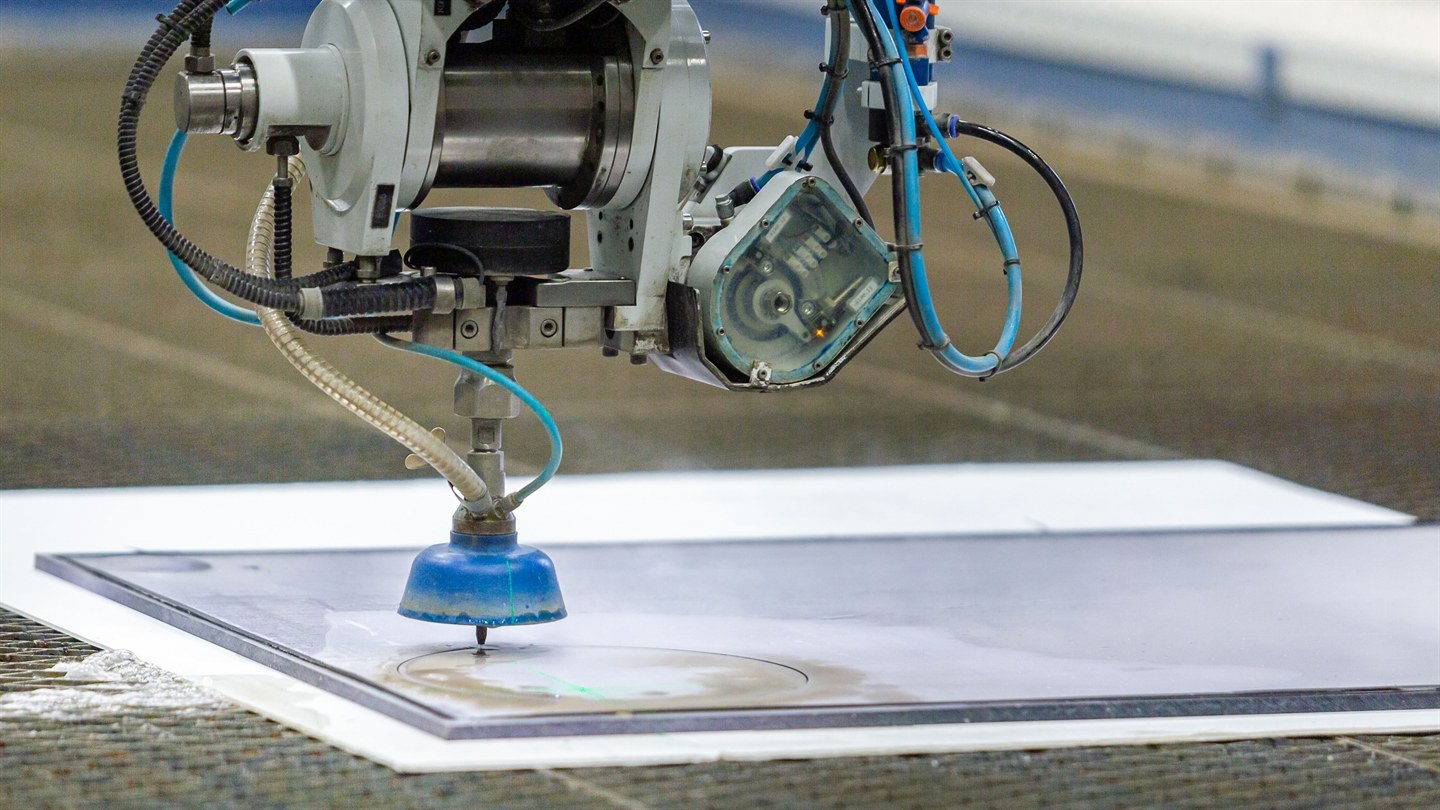

Water Jet Cutting Facility

For the process of reaping special materials, like fibre-reinforced composite, ceramics, foam, hybrid layered materials from metal and non-metallic materials, the reaping with a high-pressure jet of water up to 6,000 bar with pure water or with an abrasive water jet has become a standard procedure. With the abrasive water jet, erosive quartz sand particles are added by a special mixing nozzle that then cuts the material like a diamond wire saw.

The development of the cutting programmes as well as the supply of manifold parameters for the special materials permit reliable near shape or precise dividing cuts. Special experiences are necessary to define the starting point of holes in components if the cuttings do not touch a body edge. Here special shooting or drilling procedures that allow careful material cuttings are used.

In the field of subtractive processing of various materials, water jet technology has become essential. Various materials such as fiber composite materials, ductile metals as well as highly brittle and hybrid materials with thicknesses of up to 200 mm can be cut with a very fine water jet under low process forces and without heat input to an accuracy of less than 1/10 mm.

With the help of 3D CAM software, in addition to the creation of complex machining sequences, the corresponding support devices for the exact positioning of the components to be machined are also programmed and cut. For composite and hybrid materials, a pre-drilling unit is mounted on the 3D cutter, which prevents damage to the part when a direct type of shot is not possible.

Machine data:

CNC High-Pressure Water Jet Cutting Systems WARICUT HWE-P6040/1

Properties:

- 3D cut

- pure and abrasive water

- working area: 1,500 x 2,000 mm

- pressure up to 6,000 bar

- 80 or 120 Mesh abrasive material

Depending on the material properties, thicknesses up to 100 mm may be cut.