Progressive missiles technologies (FFT)

Duration: 2006-2009

Thrust chamber structure

The need for light-weight missile components requires structures based on ceramics. State of the art for rocket motors is metallic structures being protected by the solid fuel in the combustion chamber and layers of silica phenol in the blast tube and nozzle area. These layers serve as ablative protection of the metallic structure from thermal and erosive attack. Due to uneven degradation geometry of the nozzle, flow as well as the performance of the rocket motor are changed which is especially critical for small nozzle diameters. Thus, lighter structures have to be developed.

The development and testing of CMC materials for thrust chambers is based on new ceramic fibres, since C-fibres are limited to short term applications. Furthermore, new preform techniques will be adapted to component design as well as process conditions of CMC manufacture.

Plasma wind tunnel testing is performed to qualify the materials with respect to aerothermal loading. Practice-oriented testing of specimens is accomplished in a suitable combustion chamber.

Jet vanes

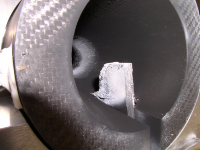

Materials and components based on C/C-SiC, developed within this project, have been tested on a suitable test bench with respect to abrasion resistance. On this test bench the conditions in a solid propellant rocket motor with a high loading of aluminium can be simulated. Testing of material specimens as well as jet vanes in original size is feasible on this versatile test facility. In contrast to a solid propellant rocket motor the time of loading can be changed. It is therefore possible to simulate loading during launch phase as well as to investigate abrasion in dependence of time of loading at lower costs compared to a complete firing test of a rocket motor.

In order to enhance the agility of missiles possible applications of jet vanes have to be expanded. Therefore, abrasion resistance and mechanical strength in the shaft area have to be improved. This shall be achieved by specific development of materials as well as application of new refractive coatings. Practice-oriented testing of specimens is accomplished in a suitable combustion chamber in order to test materials and jet vanes in original size.

Radome

In a preceding project it was demonstrated that the material OXIPOL (oxidic CMC based on polymers) is suitable as radome in principal. OXIPOL is a CMC material based on alumina silicate fibres and polysiloxane precursors. Near net-shape manufacture of complex shaped components is achieved by liquid polymer infiltration and pyrolysis. Open porosity can be tuned via reinfiltration cycles (RTM and pyrolysis). The material provides sufficient mechanical strength and successfully passed several plasma wind tunnel tests. Even at high temperatures OXIPOL showed excellent transparency for radar.

A further topic is the development of concepts for mounting of the ceramic radome to the metallic structure with respect to different materials. Thereby, the extreme differences in the coefficients of thermal expansion of all components are leading to high internal stresses, which in the extreme case can result in destruction, have to be considered.