DLR, JAXA and AIST sign cooperation in energy research

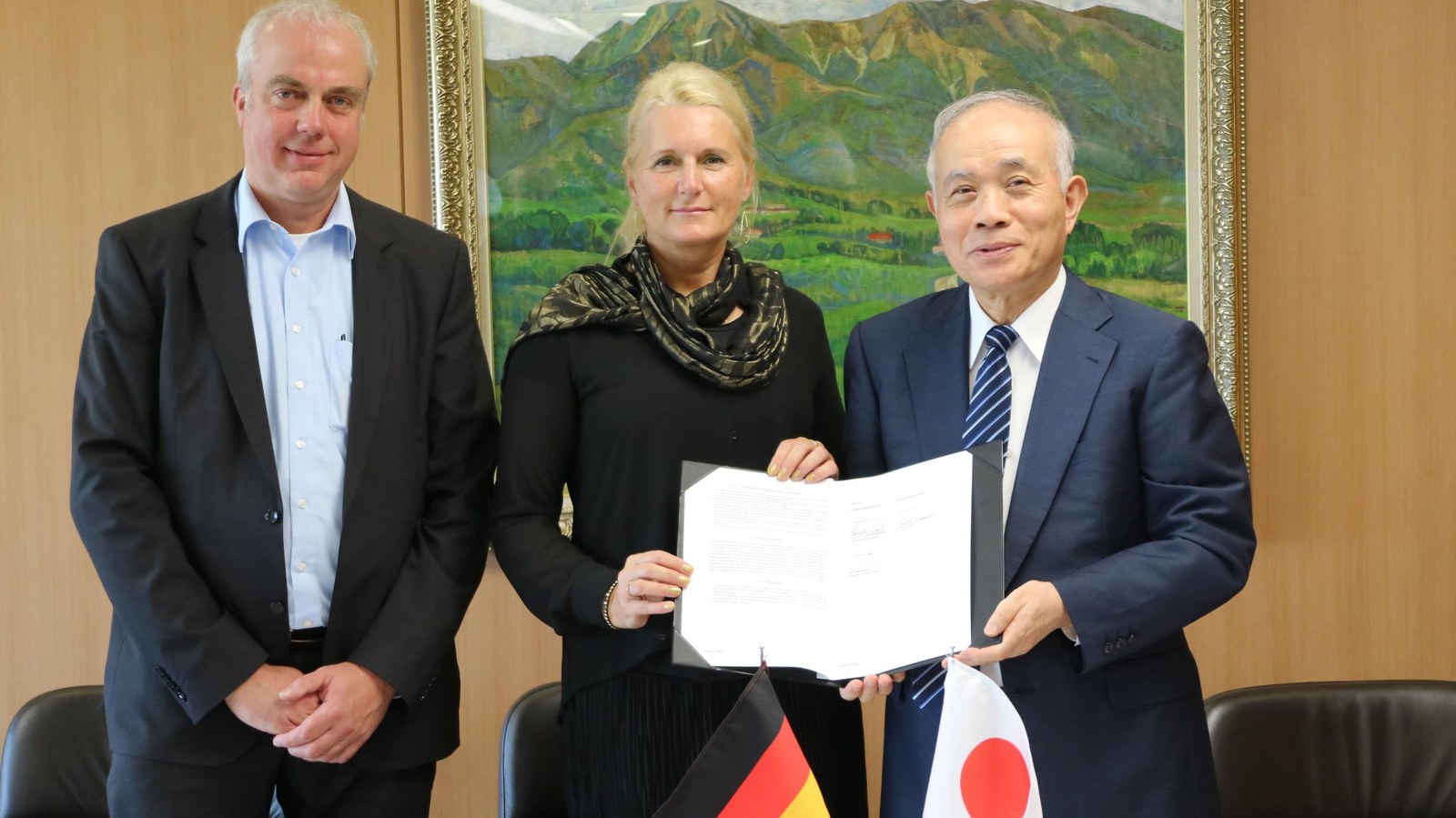

The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), the Japanese space agency, JAXA, and the Nationale Institute of Advanced Industrial Science and Technology in Japan (AIST) signed two cooperation agreements on 21 September 2017 in Tokyo. The research institutes will collaborate in future on the development of high-performance and durable batteries for space missions. The scientists will also conduct research to develop thermoelectric generators, as well as standards to measure the efficiency of their performance.

"In AIST and JAXA, DLR has found two research institutes that are highly regarded on the international stage and with whom it can explore extremely topical issues of batteries and thermoelectric energy generators. This opens up many opportunities to pool competencies and will likely produce rapid progress in joint developments," said Pascale Ehrenfreund, Chair of the DLR Executive Board, during the signing of the cooperation agreements in Tokyo.

More durable batteries for space missions

In the coming years, the Department of Computational Electrochemistry at the DLR Institute of Engineering Thermodynamics will collaborate with Japanese researchers on the development of high-performance and durable batteries for space missions. Among other things, their research in this field will focus on the Japanese satellite mission REIMEI. This satellite was equipped with one of the first modern lithium-ion batteries that has been operating for over 10 years already in space and will continue to do so for several years. Data on its battery performance has been collected since REIMEI's launch. This unique database will allow the DLR scientists to continue optimising their highly precise battery simulation. The aim is to develop a simulation method and to acquire data with which the battery condition can be predicted and influenced exactly.

The Department of Computational Electrochemistry is among the world's leading research facilities that is able to investigate and create 3D simulations of the processes at play inside a battery down to the microscale of the electrode structure. The researchers are therefore in a position to detect signs of ageing and fatigue and to identify their causes. The cycle life of the battery can be increased by means of improved design and optimised charging and discharging cycles. The research is highly relevant for electromobility and terrestrial applications as well, given the spiralling importance of batteries as energy storage units. This cooperation with AIST and JAXA is an outstanding opportunity to deploy the competencies and resources of the participating institutions in a more targeted form.

Faster development based on international standards for thermoelectric generators

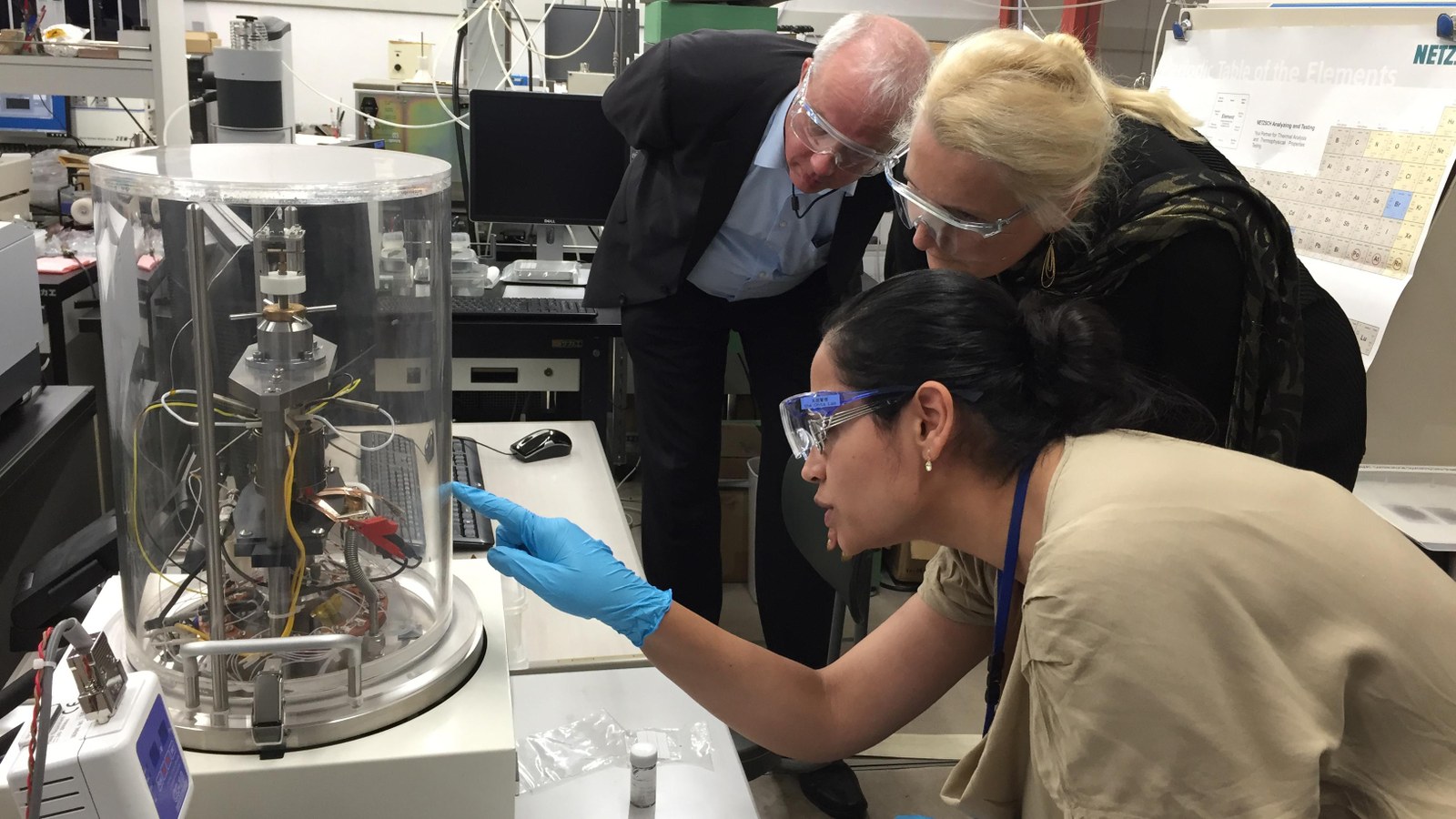

Thermoelectric generators (TEGs) convert waste heat from combustion processes into electrical energy. They can be used to increase energy efficiency in automobiles, aircraft and in stationary applications, and are suitable as independent, mobile electricity sources as well. In automobiles, for instance, converting the waste heat in exhaust fumes into electrical energy for the vehicle is expected to reduce fuel consumption by up to five percent. Laboratories worldwide are creating increasingly efficient modules – a precondition for the development of many new applications. In addition to solutions for industrial integration, another requirement for smooth transfer into the practical arena is the definition of standardised measurement procedures to determine the efficiency and performance of the TEG modules, which so far has not been done either at a national or international level. Measurement uncertainties of more than 15 percent continue to occur regularly with current measurement techniques. This is inadequate for scientific investigations and industrial developments and is delaying the market penetration of thermoelectric systems across all areas of application. Joint performance of more realistic testing will narrow the gap to the successful roll-out of a technology that has the potential to significantly reduce emissions and greenhouse gases, for instance in passenger and freight transport.

In future, the DLR Institute of Materials Research, the To the Institute's website and AIST will work on precise measurement procedures to obtain more meaningful measurement results. First, this will advance standardisation of these methods to enable reproducible and comparable findings that are in line with scientific requirements. Second, the thermoelectric generators will be measured more realistically when integrated into a motor vehicle and their efficiency can thus be improved. Intense research of thermoelectric materials and systems is currently ongoing in Japan and in Germany – both by the scientific community and in industry. Defined standards should enable the faster developments of TEGs in future. The partners will therefore be able to offer crucial support to manufacturers of thermoelectric generators and measurement systems in the market introduction of their products.