DLR researchers achieve high-temperature electrolysis with solar-thermal steam for the first time

- DLR researchers have successfully operated high-temperature electrolysis using solar-thermal steam for the first time

- They have shown that this combination of technologies is technically feasible with the help of sophisticated control technology

- This is a promising approach to produce hydrogen efficiently and in a renewable way

- Focus: Energy, future fuels, electrolysis, solar-thermal power

The production of hydrogen using renewable resources plays a key role in the sustainable transformation of the energy and mobility systems. This is because it is a multi-use energy carrier that can be used directly for clean mobility in fuel-cell vehicles, as a store for variable renewable energy sources, or as a starting point for the production of synthetic fuels. Researchers at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have, for the first time, successfully operated high-temperature electrolysis using solar-thermal steam – thus implementing a promising laboratory scale approach to the renewable production of hydrogen.

Sophisticated control technology for successful coupling

In electrolysis, water is split into its constituent elements – hydrogen and oxygen – using electricity. "The challenge in this particular project was linking the two components – high-temperature electrolysis and solar-thermal steam generation. The demands placed on the control technology are very high, which is why this combination has not previously been realised," summarised Günter Schiller, a researcher at the DLR Institute of Engineering Thermodynamics in Stuttgart.

High-temperature electrolysis has a very high efficiency – more than 90 percent. It is thus the most efficient type of hydrogen production, but requires temperatures of between 700 and 900 degrees Celsius. Processes at this temperature level are difficult to manage. Low-temperature electrolysis, on the other hand, operates at around 70 to 100 degrees Celsius and is already commercially available. However, it is characterised by a lower efficiency – between 60 and 80 percent.

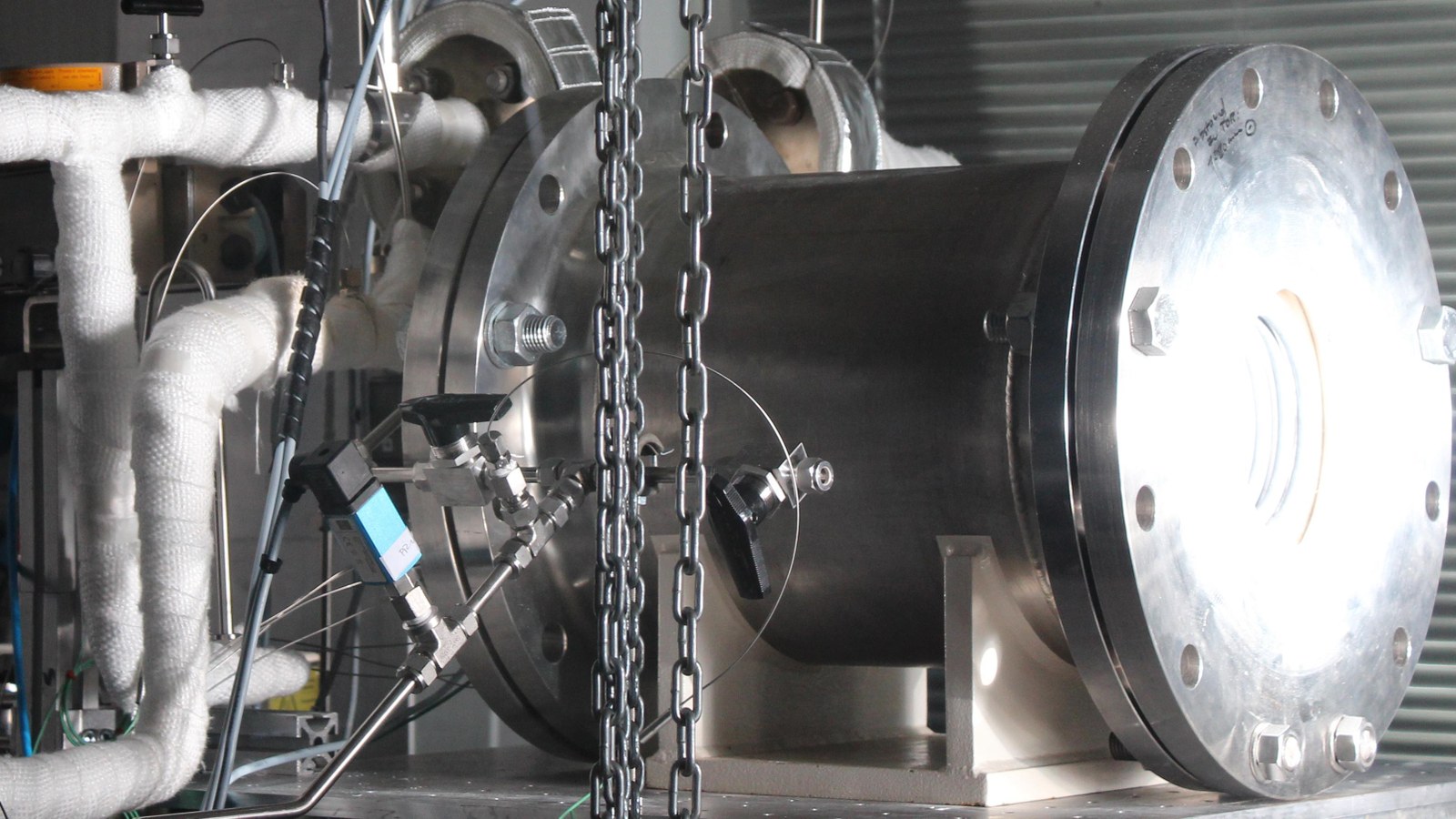

To generate the steam required for electrolysis at approximately 750 degrees Celsius, researchers primarily used solar heat and the heat of the high-temperature electrolysis unit. To this end, a special solar heat absorber – the technical term being a receiver – captured the radiation from an artificial Sun in the solar simulator at the DLR Institute of Solar Research in DLR site Cologne, Headquarters. Water passing through the receiver turned into steam. 'The most difficult part was generating a steam supply that was as constant and stable as possible, because high-temperature electrolysis does not tolerate fluctuations in pressure. Changes in steam pressure can damage the cells in the electrolysis stack," explained Henrik von Storch from the Institute of Solar Research. Control technology was also required at this point, so that the miniature hydrogen power plant could be assembled and tested in an experiment.

From miniature power plant in the laboratory to application concepts

To guarantee a reliable supply of steam even when the Sun either does not shine or does not shine with sufficient intensity, the DLR energy researchers from the Institute of Engineering Thermodynamics also developed a concept for a suitable thermal store, and implemented this on a separate test stand.

Initial simulations have shown that hydrogen can be generated in a renewable manner at an overall efficiency of between 20 and 25 percent if high-temperature electrolysis and solar-thermal energy are combined. The size of solar-thermal installations can be scaled up relatively easily; electrolysis systems can be expanded in a modular manner. Therefore, the researchers have concluded that very large installations with capacities of more than 100 megawatts are feasible. In the long term, these may represent an environment-friendly alternative for the renewable production of fuels.