Biofilters designed for space convert liquid manure into high-quality fertilisers

- The C.R.O.P.® method can make nutrient cycles sustainable and environmentally friendly.

- Biologically produced fertiliser solutions help to protect soil and water.

- The biofilter was originally developed for astronauts to ensure the supply of fresh food on long-duration missions.

- Focus: Space, technology transfer, environment, sustainability

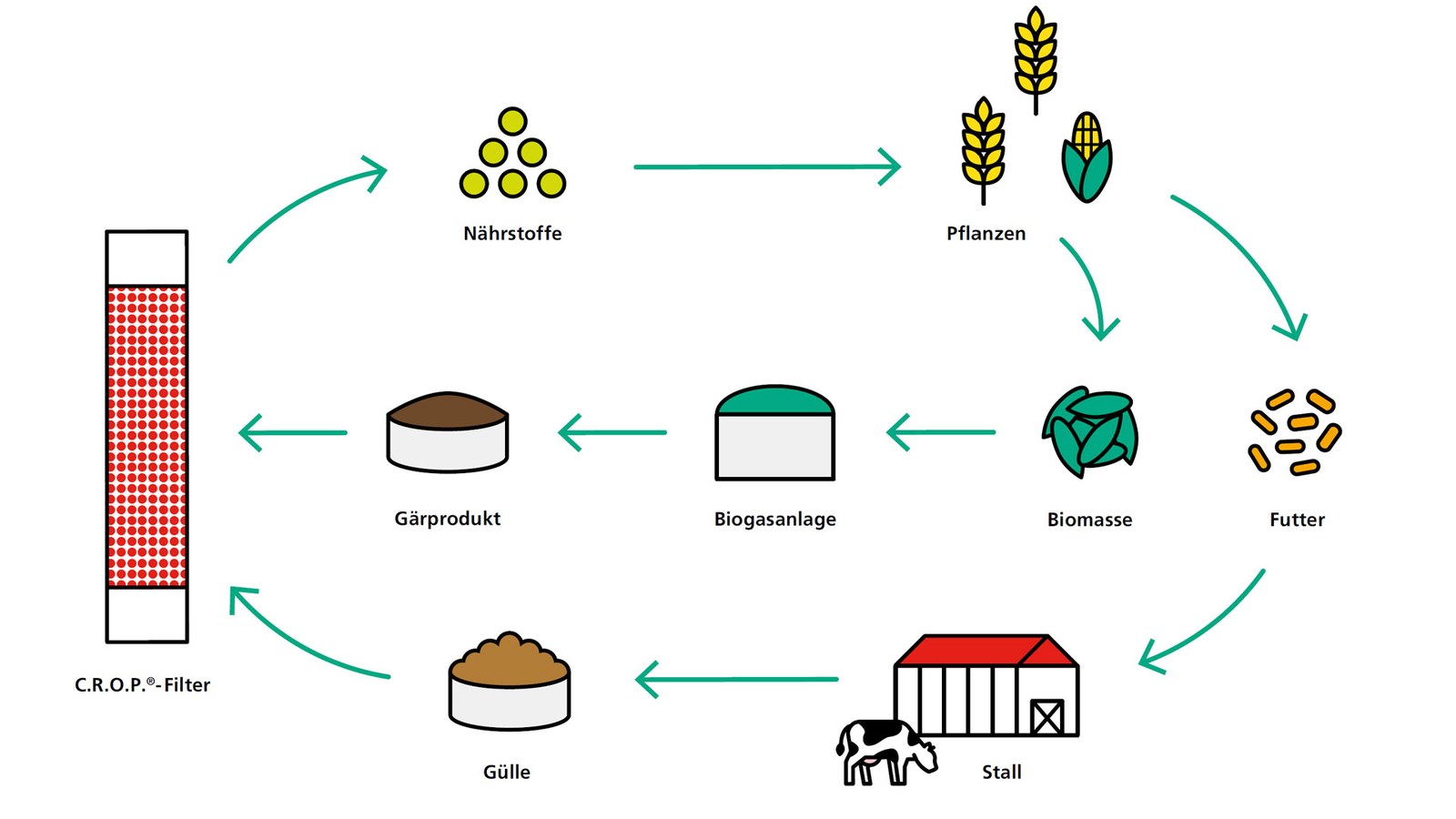

The technology was originally designed for space: urine and waste are used to create a fertiliser that can help astronauts grow produce like tomatoes or lettuce. Now, this technology, made possible by the Combined Regenerative Organic food Production (C.R.O.P.®) biofilter – developed at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) – is proving useful on Earth in organic manure processing. A market study involving farmers is currently underway. At the same time, the biofilter is being further adapted and scaled. The first field test in the BiG C.R.O.P® project will start in late autumn 2021.

"C.R.O.P.® is a purely organic method of processing nitrogen-containing wastewater into a fertiliser solution," explains Project Manager Tim Paulke of the DLR Institute of Aerospace Medicine in Cologne. "The principle does not just apply to urine, either. It can also be used to treat farm slurry such as cattle manure or the products of fermentation without any issues." This could lead to a reduction in the use of mineral fertilisers in mainstream agriculture. The system prevents excess nitrogen from entering ecosystems in the air, water or soil.

Microorganisms process nitrogen in the 'reaction chamber'

The C.R.O.P® method does not require any artificial chemicals or hazardous substances, but instead relies on natural metabolic processes. The system consists of a tank and a 'reaction chamber', which contains a large number of microorganisms. Bacteria, fungi and protozoa form an adaptable ecosystem that can process all sorts of substances, from nitrogen to phosphorus. "In the process, we see the propagation of the organisms that serve as a nutritional basis for the respective substances," says gravitational biologist Jens Hauslage. The idea of biofilters is far from new – the Institute of Aerospace Medicine has been researching scenarios for specific habitats and applications since 2011. It is also conceivable that C.R.O.P.® could be used in cities: the filter system could clean sewage in residential areas and be accommodated within houses to save space. It is also capable of treating wastewater that is contaminated with medicines or drugs.

Possible application for greenhouses on the Moon or Mars

C.R.O.P.® was originally developed for missions in space. Astronauts on long-duration missions need closed life support systems. This would also apply to stations on Mars or the Moon, where people would require a supply of breathing air, water and food that would need to be recycled wherever possible. Researchers could, for example, operate a greenhouse with treated wastewater.

Market study

Market study and field testing boost the potential for technology transfer from space to agriculture. Provided that the local conditions are right, interested farmers can deploy a pilot system on their land for a specific period of time. Slurry and fermentation products from a biogas facility can be processed into a higher-quality fertiliser on site using a C.R.O.P.® system. The fertiliser solution can be used directly on plants and does not emit any unpleasant odours.