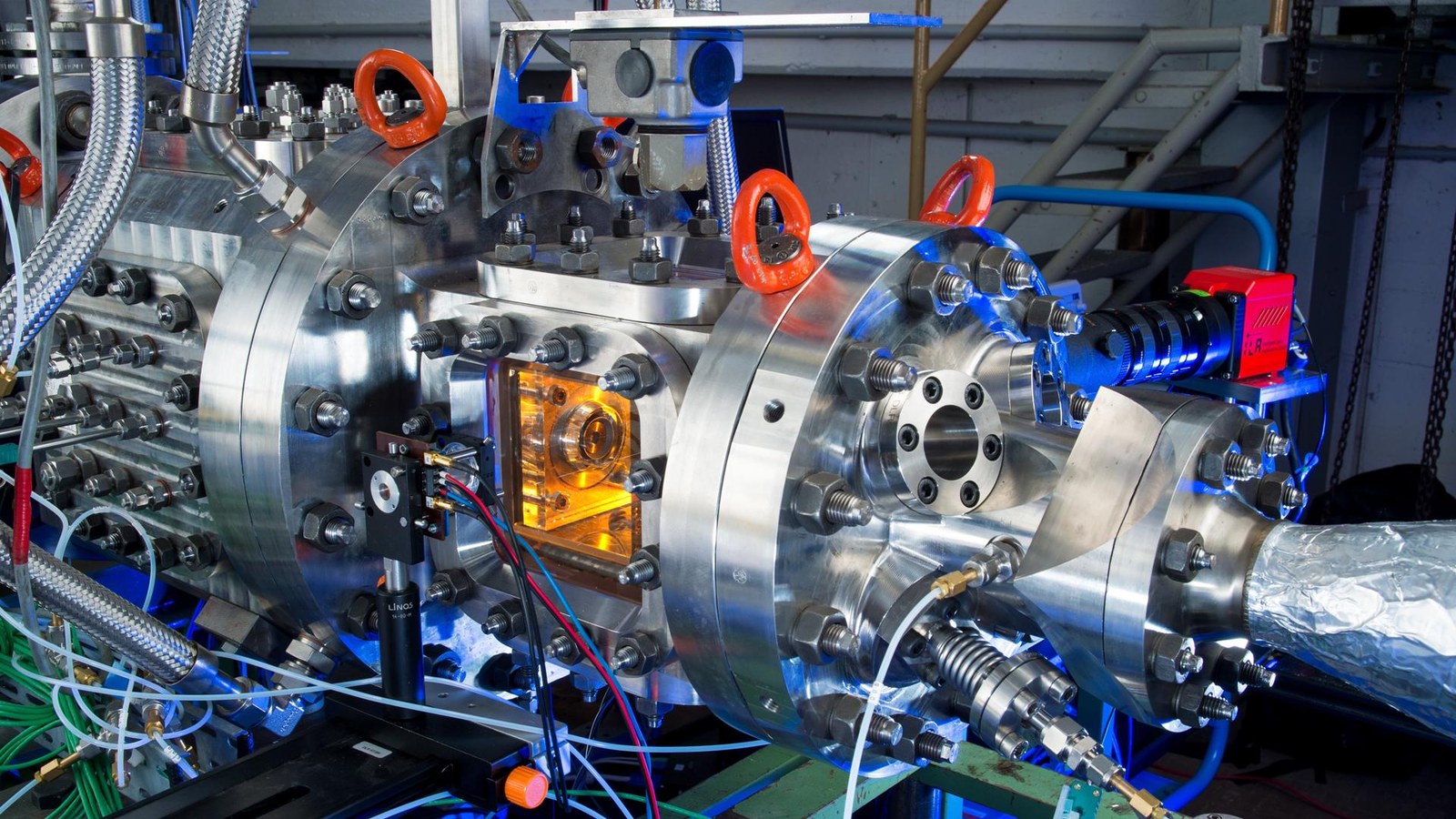

Pre-Evaporator Test Stand / Optical High-Pressure Atomiser (OHZ)

This measurement facility at the Institute of Propulsion Technology in Cologne offers the possibility of investigating the atomisation, evaporation and mixing of kerosene under realistic conditions using optical methods.

Optical investigation of fuel in gas turbines

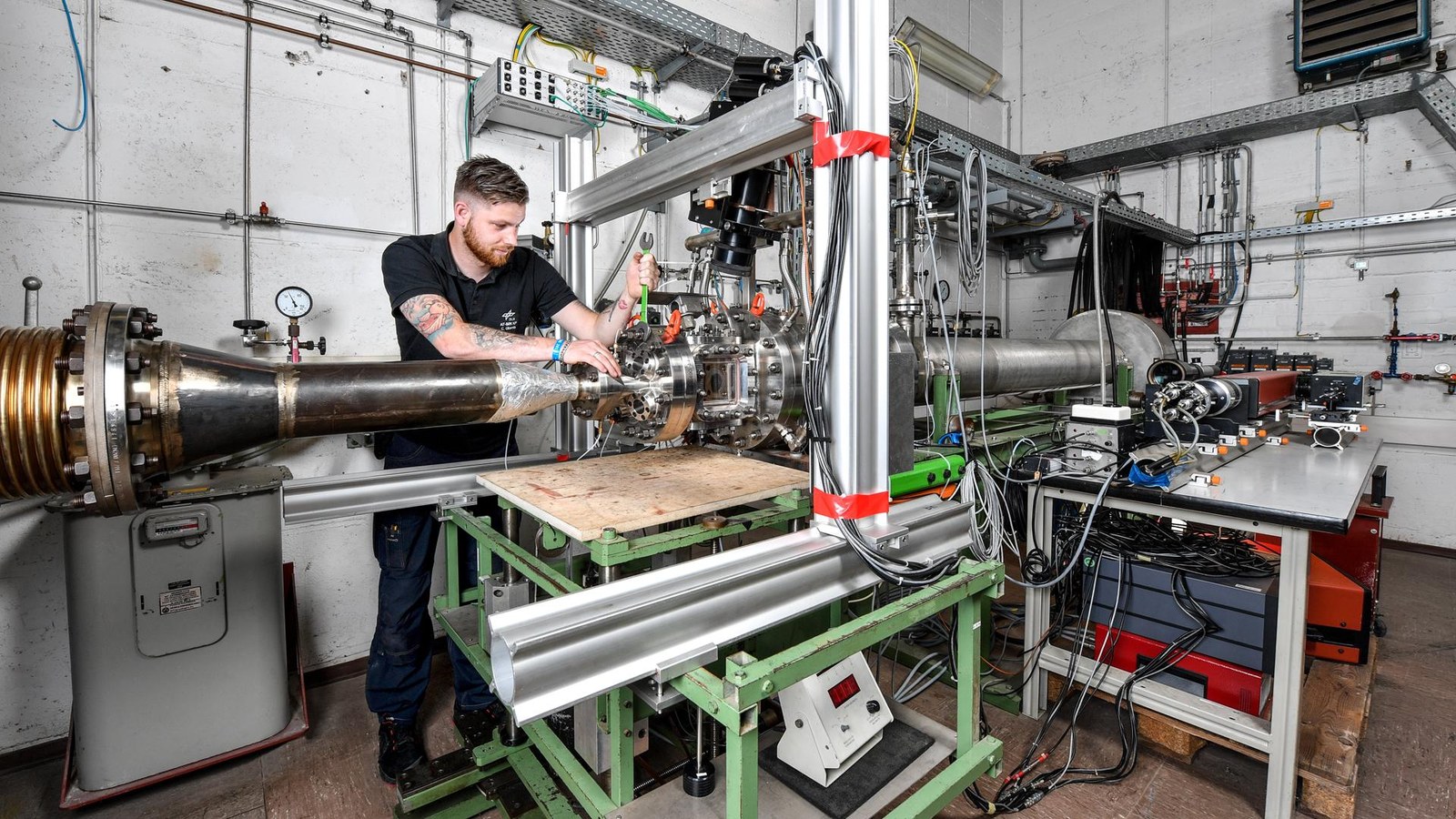

Researchers at German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) are investigating the precise processing of liquid kerosene in newly developed burners at the OHZ facility in Cologne, also referred to as the Pre-Evaporator Test Stand. Flow rate and the high operating pressures and temperatures typically found in combustion chambers have a significant influence on the atomisation, evaporation and mixing of liquid fuel.

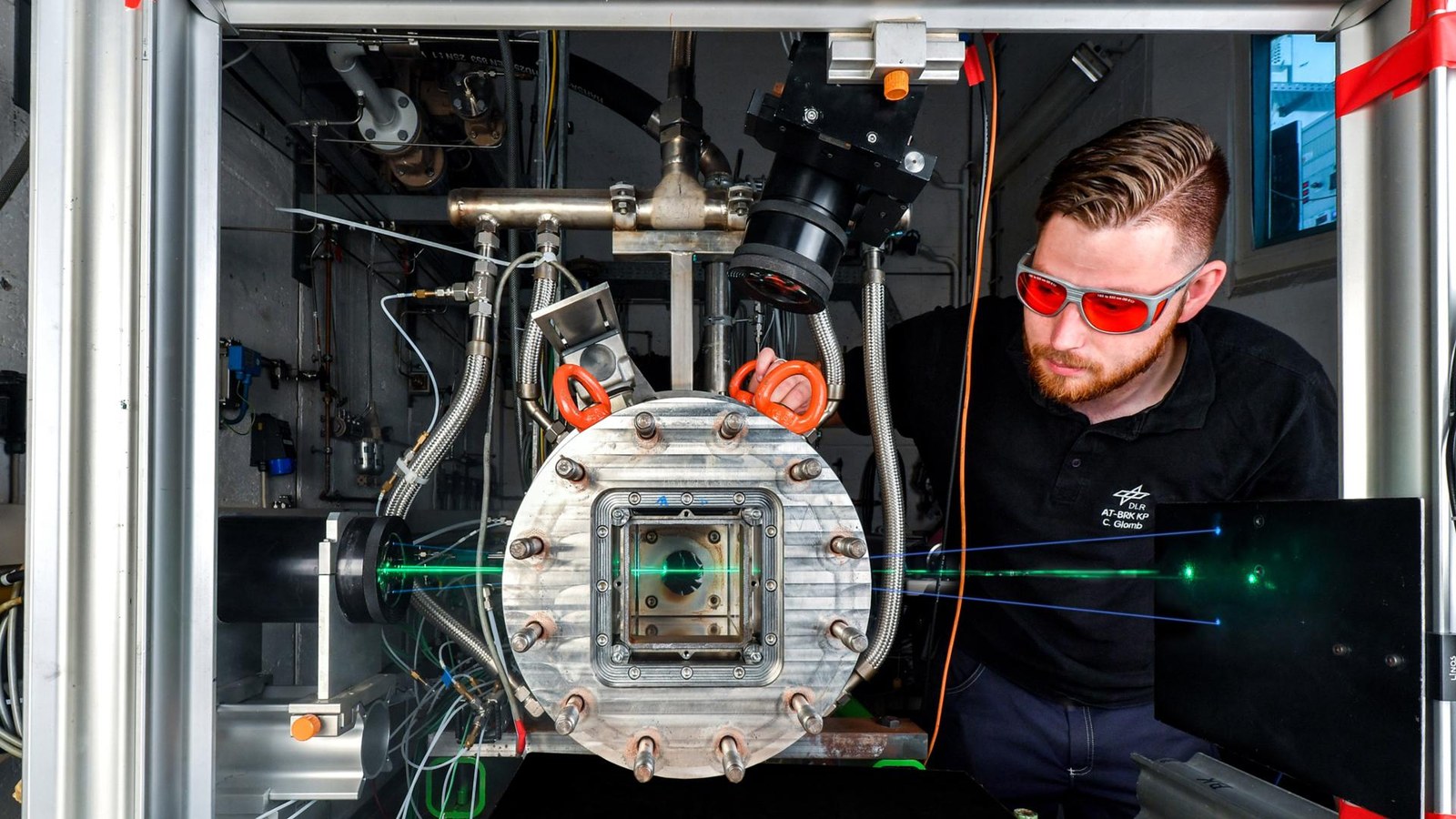

The OHZ and its Optical Swirling Spray Injector (OSSI) measuring facility were designed precisely for these areas of operation. The introduced kerosene is catalytically post-combusted in the exhaust gas system. The high-pressure windows enable the use of numerous laser-optical measurement methods. As a result, the test stand has already been used to obtain novel experimental data, which has gone on to be used in the design processes of several European engine manufacturers. In addition, data sets published by various research partners are used to validate numerical simulations.

The aim of the system is to optically investigate the fuel preparation process for gas turbine burners under realistic operating conditions and thus gain important insights into their operating behaviour and emissions.