The race to zero with ZEDU

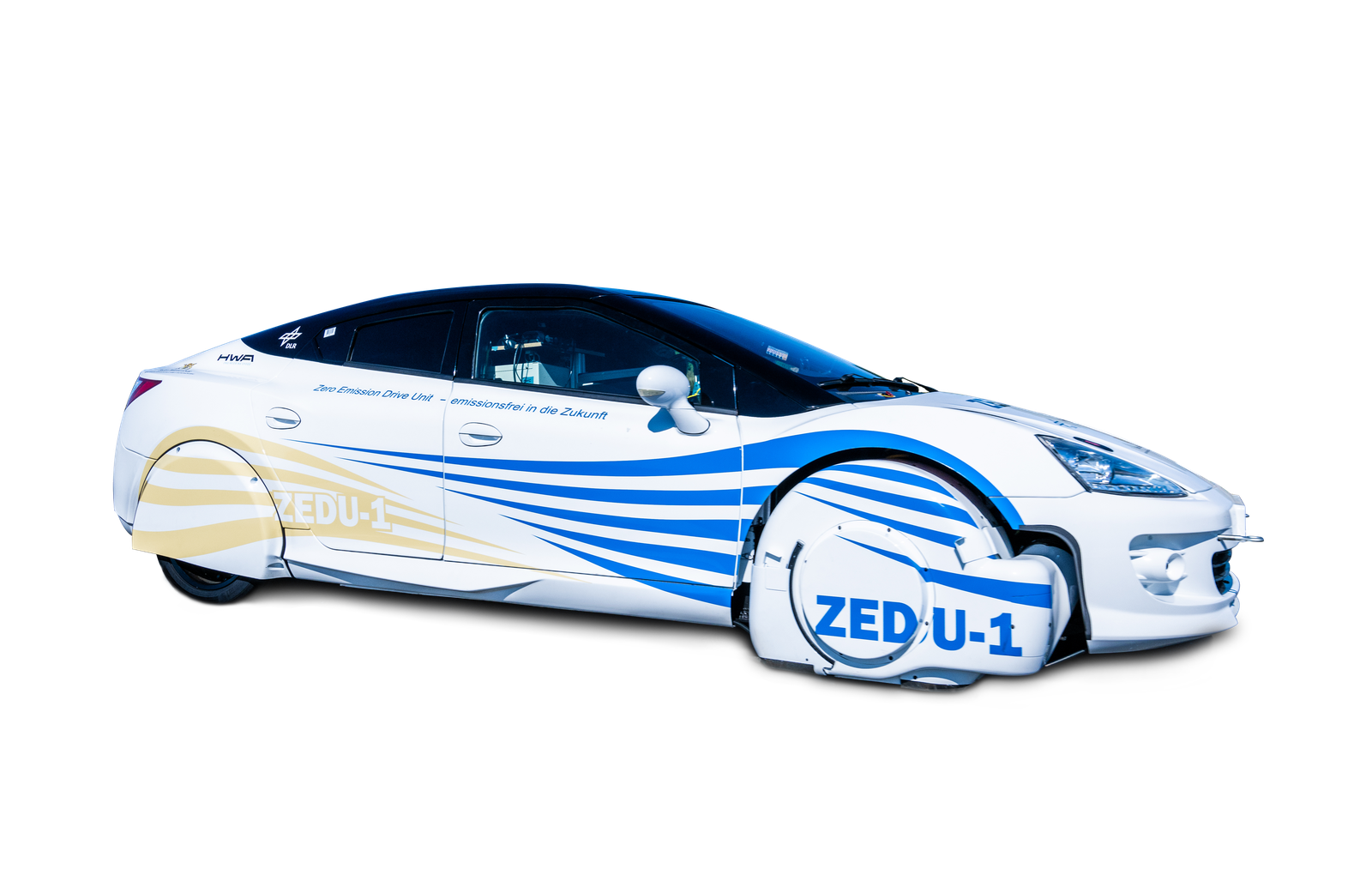

Electric drive systems powered by batteries or fuel cells are an essential part of the scientific advance towards environmentally friendly road transport. However, they do not yet enable completely emission-free driving. Abrasion from brakes and tyres produces particulate matter and microplastics. DLR's ZEDU test car, a world first, aims to eliminate these pollutants using an innovative braking system and a redesigned wheel housing.

Stuttgart, the capital of Baden-Württemberg, is considered one of the birthplaces of the automobile. But for a long time, the Swabian metropolis held the rather inglorious distinction of having the highest levels of fine dust pollution of any city in Germany. Stuttgart breached the European threshold values introduced in the 2000s more frequently than anywhere else in the country. Particulate matter is invisible to the human eye. It consists of particles that float in the air for a long time before falling to the ground. The smallest of these particles can enter the lungs via the respiratory tract and, from there, enter the bloodstream. When deposited in the blood, they can pose a health risk. Traffic causes about half of the particulate matter. It is generated during combustion processes in the engine and through the abrasion of brakes and tyres. A similar situation exists for plastics: every year, road traffic generates between 133,000 and 165,000 tonnes of plastic matter that is left in the surrounding environment, primarily as a result of tyre wear. Particles smaller than five millimetres, known as microplastics, are exceptionally problematic. They have now been detected almost everywhere on Earth and can take several hundred years to decompose.

"A car that you can sit in and drive makes a very different impression to its individual components."

Franz Philipps, Team leader at the DLR Institute of Vehicle Concepts

Driving without particulate matter and microplastic emissions

"In our advances towards zero-emission mobility, the focus has been on how to replace the internal combustion engine as a propulsion system in order to drastically reduce emissions of the greenhouse gas carbon dioxide. From 2035, the EU will only allow new cars to be registered that do not emit carbon dioxide when driven. Emissions such as particulate matter and microplastics generated from brake and tyre abrasion will then come into focus. In order to prevent them, we need new technologies and solutions, and we need to advocate for and develop them now," explains Project Lead Franz Philipps from the DLR Institute of Vehicle Concepts in Stuttgart. "That is the underlying motivation for the ZEDU-1 project." Philipps and his team have broken new scientific ground with their 'Zero-Emission Drive Unit – Generation 1' (ZEDU-1) and set themselves an ambitious challenge: to develop the most environmentally friendly car in the world.

From zero to prototype in two years

From early on, it was clear that the ZEDU-1 team and their industry partners wanted to install their newly developed technologies in a vehicle and demonstrate them in operation. They created a unique prototype with a distinctive design. "A car that you can sit in and drive makes a very different impression to its individual components," says Philipps. In addition to the increased attention from industry, policymakers and the public that such a prototype can generate, there was another factor behind the decision: "Working on an existing vehicle would have been difficult, as large manufacturers are reluctant to provide the kind of precise insights into vehicle design, central systems and the control mechanisms that we would need." The team began with a specification sheet – an understatement of a term for the vital document holding all of the vehicle's requirements and planning details.

The aim was to create a battery or fuel cellpowered car with no internal combustion and with a top speed of 150 kilometres per hour. Brake and tyre wear were to be either eliminated or reduced to the absolute minimum. The braking system was to be designed to recover energy from the braking process and reliably provide full braking power at all times. The entire vehicle, including its control systems, power electronics and all energy and heat flows was to be as efficient as possible. From the start, the team approached the design and assembly of each component in a way that would be relatively easy to scale up to series production. "No one had ever done this before. With ZEDU-1, we created a blueprint for future projects and set standards. That was both an incentive and a challenge for the whole team," recalls Philipps. The car manufacturer HWA from Affalterbach in Swabia joined the project as the primary industry partner. With their origins in racing, high-quality, innovative braking systems and aerodynamics are part of the company's day-to-day business.

In March 2020, the project received the green light and was granted approximately six million euros in funding from the Baden-Württemberg Ministry of Economic Affairs – just as the COVID-19 pandemic first swept through Europe. Supply chains broke down, components were not available for months and only employees who were completely indispensable were allowed to work on site with the vehicle. "For us, that meant being flexible, constantly improvising and working together digitally as effectively as possible. We would often send each other pictures showing the current status of the parts and the entire vehicle, rather than being able to see and touch the technology ourselves," continues Philipps. In the summer of 2022, however, what had long seemed unlikely finally became a reality as the ZEDU-1 prototype was rolled out for extensive testing. It was unveiled to the public in September – a well-deserved reward for the team's remarkable efforts.

Braking system eliminates particulate matter

The crucial new feature of the ZEDU-1 is its braking system. The researchers developed a special multi-disc brake that is integrated into the closed unit of the electric motor and gearbox rather than installed in the wheel. This reduces the size of the brake components to a minimum and enables the drive unit to be constructed in a very compact way. In conjunction with specially developed high-performance electronics, it is now possible to almost completely recover the energy used by the brakes. This recuperation is not limited to ten percent of the braking force thanks to features such as the Electronic Stability Programme (ESP) and the Anti-lock Braking System (ABS). The result is that ZEDU-1 is a highly efficient vehicle in which 75 percent of the braking energy is recuperated on the front axle and 100 percent on the rear axle even under maximum braking energy.

The brake discs consist of seven ring plates. Every second one of them is geared to the shaft of the electric motor, with the others geared to the housing. When braking, the ring plates are pressed together by an actuator and filled with oil. In doing so, the material produced by abrasion also ends up in the oil, which is continuously pumped through a filter and cleaned. The brake is activated electrically, rather than mechanically. In technical jargon, this is known as 'brake by wire', as an electronic signal is sent to the brake to activate it.

The team also developed a hybrid induction brake for the ZEDU-1 prototype. The brake can bring the vehicle almost to a standstill entirely wear-free using magnetic forces. Generating the braking effect all the way to a standstill requires the installation of an additional friction element, which is designed to mechanically supplement the magnetic braking force automatically as it decreases. "For us, this meant redesigning not only the vehicle control system but also the entire operation of the brake and programming the corresponding software," explains DLR researcher Franz Philipps. The induction brake has not yet been integrated into the prototype. The researchers hope to achieve this further in the next step of the project.

Redesigned wheel housing siphons off microplastics

Relocating the brakes from the wheel housing to the inside of the vehicle creates space for new technological approaches to reducing tyre abrasion. The basis for this is the enclosure of the The DLR researchers first generated a baseline dataset for a standard electric vehicle and determined the emissions from the brakes and tyres separately to provide a reference. To do this, they used one of the institute's standard electric vehicles, equipped it with measuring instruments and carried out initial tests on the on-site roller dynamometer and on the road. "Test routes and normal roads already have a lot of dust on them. You can't tell exactly what was produced by the wheels: the closed wheel housing of the ZEDU-1 is aerodynamically designed to create negative pressure during driving. As a result, tyre abrasion accumulates at a specific point. A fan unit at the front of the vehicle extracts the particles here and passes them through a filter system in a similar way to a vacuum cleaner. Only filtered air is allowed to exit the vehicle. This technology presented the team with a number of additional challenges. For instance, the housing had to allow for certain steering angles to ensure that the tyres did not touch the panelling when cornering. Regardless of the speed, the new solutions had to work steadily and reliably. The wheel housing also improves the aerodynamics and thus the efficiency of the vehicle.

Put to the test on the dynamometer

In parallel to the development of the ZEDU-1, the project team developed a concept to measure its particulate matter and microplastic emissions under real driving conditions. This required equipping the vehicle with special devices and sensors. "Until now, it has only been possible to measure brake and tyre wear to a limited extent, and it has tended to be restricted to individual components in a laboratory environment. We had to come up with some new techniques to conduct measurements on a moving car," says Philipps. The DLR researchers first generated a baseline dataset for a standard electric vehicle and determined the emissions from the brakes and tyres separately to provide a reference. To do this, they used one of the institute's standard electric vehicles, equipped it with measuring instruments and carried out initial tests on the on-site roller dynamometer and on the road. "Test routes and normal roads already have a lot of dust on them. You can't tell exactly what was produced by the test vehicle and what was already there. That's why tests under controlled conditions on the roller dynamometer are so important," says Philipps.

The researchers then began to explore other questions, including the behaviour of the air flowing around the car – around the tyres and brakes in particular – the strength of these air currents, the distribution of the abrasion particles and how temperature affects the measurements. They moved systematically, evaluating the collected data after each round of tests and honing the measurement concepts and technology. The ZEDU-1 team received support from the DLR Institute of Combustion Technology, also based in Stuttgart, which is equipped with state-of-the-art measuring devices and sensors and staff with plenty of experience measuring particle concentrations, emissions and ambient air. With this equipment and expertise, the institute can detect and gauge particulate matter down to an ultrafine level. Together, the researchers determined the total particulate matter emissions and the size distribution of the particles.

An important aspect of this measurement work was that it built upon the worldwide harmonised light vehicle test cycles (WLTC), an internationally standardised process for measuring vehicle emissions. The DLR team also defined its own standard-compliant real drive emission (RDE) test cycle using city, interurban and motorway route sections in the Stuttgart region. They also carried out special braking manoeuvres at different speeds and temperatures and recorded the resulting emissions.

"Our main focus was on making the best possible use of the opportunity to carry out extensive measurements and come away with a treasure trove of data for evaluation, but of course, that didn't stop us enjoying the driving itself."

Franz Philipps, Team leader at the DLR Institute of Vehicle Concepts

Boxberg test route – a debut excursion on tarmac

For the team, the big moment finally arrived at the beginning of August 2022 when they were able to watch their creation put through its paces for a week at the Boxberg test centre. The centre is usually a facility used by car manufactures for vehicle testing, driver safety training courses or thrill-seeking amateur racers. This was where ZEDU-1 completed its first tests away from home. Although all of the team members were itching to be in the driving seat, only two were lucky enough to get behind the wheel. This is because drivers required a special training to use the test site in north-eastern Baden-Württemberg and an extra briefing specific to ZEDU-1, as the DLR prototype differs significantly from the standard vehicle. This covered topics such as how the steering reacts to certain manoeuvres, the meanings of the various warning lights and how the vehicle behaves at higher speeds. It was an exciting, adrenaline-fuelled experience.

"Our main focus was on making the best possible use of the opportunity to carry out extensive measurements and come away with a treasure trove of data for evaluation," recalls Philipps. "But of course, that didn't stop us enjoying the driving itself." As on the roller dynamometer, ZEDU-1 tackled different driving profiles and cycles, and repeatedly carried out specific braking manoeuvres. Unlike in the laboratory, however, the vehicle could now test its cornering. Researchers from the DLR Institute of Combustion Technology also attended the event. With their mobile measuring vehicle on site, they were able to evaluate the initial data from the test drives in real time.

No brake wear and significantly less tyre wear

Having evaluated the data, the ZEDU-1 team is convinced of their findings. "Our figures show that our approach can avoid brake wear altogether. As predicted by our simulations, the tyres expelled virtually no abrasion emissions into the environment up to a speed of 60 kilometres per hour. Even at higher speeds of up to 120 kilometres per hour, we were able to reduce them by 80 to 90 percent," summarises project manager Franz Philipps. The team also generated a large amount of data during the measurement campaigns and developed new measurement concepts. Both have the potential to drive major advances in research and industryrelated development toward climate-friendly mobility, whether in terms of tyre compounds, new brake systems or filter concepts. The media coverage of ZEDU-1 reached far beyond Germany and demonstrates that the project has struck a chord. Companies in the supply industry and brake and tyre manufacturers have also expressed an interest. The introduction of the Euro 7 standard for passenger cars and light commercial vehicles planned for 2025 will address the entire size spectrum of ultrafine dust and define threshold values for emissions from brakes and tyres. The issue of particulate matter and microplastic emissions isn't likely to disappear from the political agenda any time soon.

All-wheel roller dynamometer with climate chamber

The 'roller' is one of the DLR's unique large-scale research facilities and is located at the Institute of Vehicle Concepts in Stuttgart. Future vehicle drives are developed and tested here using the latest equipment and techniques. For this purpose, test vehicles are permanently mounted on the roller test bench and, for example, road travel is simulated. When driving, the wheels turn on rollers in the floor of the facility. This replicates specific driving cycles and route profiles under controlled conditions and allows energy consumption and emissions to be measured. The dynamometer is housed in a climate chamber which can maintain temperatures from negative 40 to positive 60 degrees Celsius and humidity between zero and 80 percent. The maximum speed at which vehicles can be tested is 200 kilometres per hour. The facility can be air-conditioned and is also suitable for testing hydrogen vehicles. It is used both for research projects and for tests by industrial companies.

An article by Denise Nüssle from the DLRmagazine 172