SESAM

DLR / Unsplash

Synergy effects in the solar production of ammonia and fertilisers

Duration: 01.12.2019 – 31.03.2023

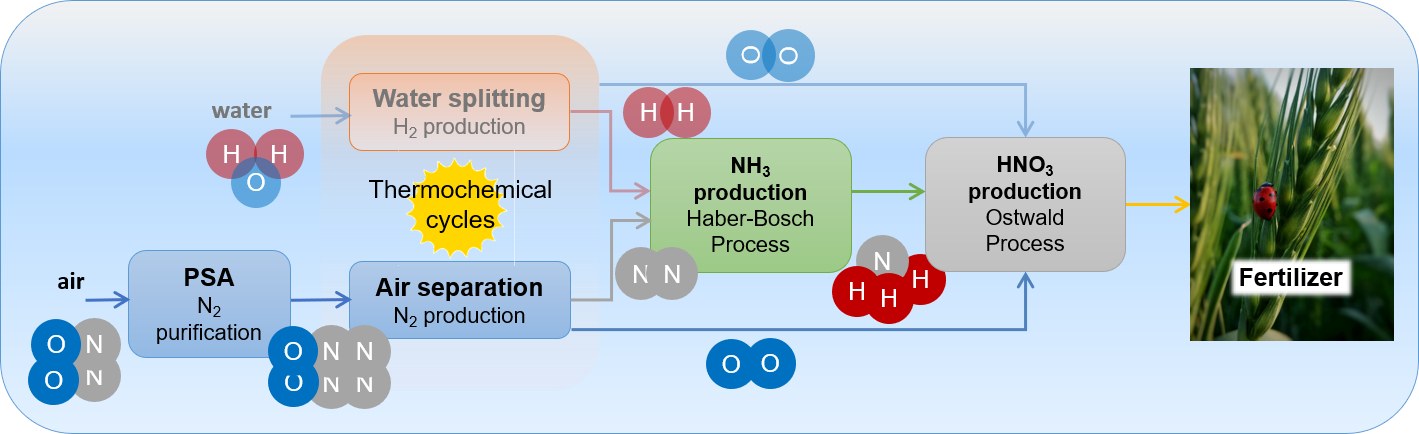

The state of the technology is the production of nitrogen by means of cryogenic air separation. However, this releases large amounts of CO2. An alternative production option is thermochemical air separation, which can be operated in a CO2-neutral manner due to the use of solar heat. In a previous project (Düsol), the feasibility of solar thermochemical air separation using perovskites as redox material was demonstrated.

The profitability calculations showed that the efficiency of the process can be increased by coupling the thermochemical air separation with pressure swing adsorption (PSA). In the proposed two-stage air separation, the PSA plant produces nitrogen of low purity and then most of the residual oxygen is removed in the thermochemical cycle, so that very low oxygen partial pressures are achieved.

In the SESAM project, this process is to be demonstrated in a pilot plant in order to further increase the efficiency of the overall process and to demonstrate industrial feasibility. The nitrogen gas product should achieve the purity of less than 10 ppm oxygen contamination required for the Haber-Bosch process.

The by-product of air separation is either oxygen-enriched air or pure oxygen in the thermochemical stage, which has the potential to be used for more efficient nitric acid production. Nitric acid is the starting material for the fertiliser synthesis of ammonium nitrate. This synergy effect between air separation and nitric acid production is to be investigated and demonstrated on a laboratory scale.

Through the intensive involvement of industrial partners and a continuous profitability analysis during the entire project period, SESAM places a clear focus on application orientation.

The role of the associated partner is focused on providing advice and sharing knowledge, as these have experience in industrial ammonia and nitric acid.

Project | SESAM |

|---|---|

Duration | 01.12.2019 – 31.03.2023 |

Project participants | |

Funding |

News from the project

Multimedia

Video: DLR project SESAM – producing high-purity nitrogen with solar energy (in German)

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.