Institute of Solar Research

The Institute of Solar Research develops concentrating solar systems for the generation of heat, power and fuel.

Duration: 1.10.2018 – 31.7.2022

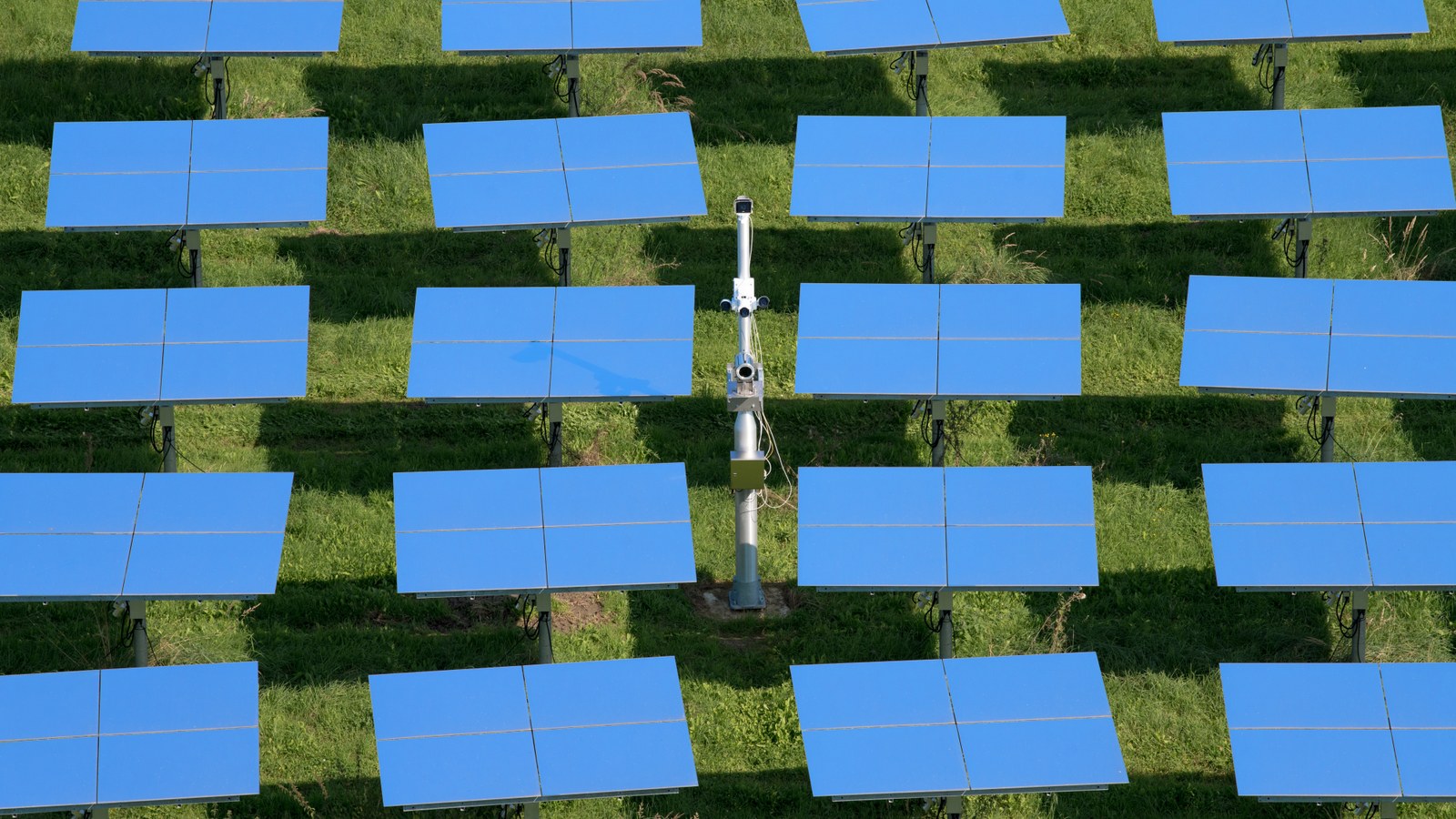

Thermochemical redox cycle processes for producing hydrogen, which take place on a solar tower, require higher temperatures than processes for generating electricity. In addition, these processes sometimes require the process parameters, such as the temperature, to be adjusted over time. This results in special requirements for the heliostat field: the mirrors must concentrate the solar radiation to a higher degree and must therefore be manufactured more precisely and be able to track the sun more accurately.

The H2Loop project addresses this. Researchers are developing a fully automated control system using a heliostat field for the process temperature in such a solar-chemical multi-chamber reactor. The novel, quasi-closed loop control concept (H2Loop) is based on several innovations: a model-based optimisation tool, a real-time communication network, an online calibration process for the heliostats and a new high-focus heliostat.

In the model-based optimisation tool developed by DLR, the future state (temperatures, degrees of reaction and partial pressures) of the solar receiver consisting of several reactor chambers is to be calculated and optimised in such a way that as much hydrogen as possible is produced and safe operation is ensured at the same time. To this end, the tool should suggest which reactors the heliostats should target and when, i.e. how the available solar power should be distributed to the individual reactors.

A new high-focus heliostat is being developed by Hilger GmbH in order to come as close as possible to the distribution of solar radiation on the solar panel required by the optimisation tool. Improvements, including in drive technology and production engineering, are intended to increase accuracy and reduce costs.

Synhelion Germany GmbH is in charge of developing a real-time communication network between the individual heliostats in the field and the power plant's control centre. To this end, the researchers are harmonising the communication hardware on the heliostats and the network protocol so that they transmit the information reliably in both directions and with only minimal and acceptable delays.

The online calibration process developed by the Solar Institute Jülich (SIJ) is intended to enable alignment errors in the heliostats to be recognised and corrected directly during operation. Several methods are being evaluated and tested, including a laser-based and a camera-based method. Online calibration will further improve the tracking accuracy.

The innovations mentioned are intended to enable control of the hydrogen production process and increase its yield. Together with the cost reduction of the individual components, this should increase the economic efficiency of solar hydrogen production.

Project | H2Loop |

|---|---|

Duration | 1.10.2018 - 31.7.2022 |

Project participants |

|

Funding | European Regional Development Fund (ERDF) "Investments in Growth and Employment" as part of the Lead Market Competition Energieumweltwirtschaft.NRW |