CALyPSOL

Calcium oxide looping through solar energy

Duration: 1.8.2018 – 31.7.2021

Calcium oxid looping means the transformation of lime (CaO) into limestone (CaCO3) and vice versa. It is a conventional, energy intensive process for the sequestration of carbon dioxide (CO2) from industrial exhaust gases. CALyPSOL tries to operate this process with solar energy. A reactor for the calcination (the endothermic transformation of CaCO3 into CaO und CO2) will be developed for operation with concentrated solar radiation. The complete process will be demonstrated in the High-Flux Solar Furnace of DLR in Cologne-Porz.

The main objective of this project is the separation of CO2 from exhaust gases of industrial processes via a well-known chemical process, which will be operated with concentrated solar energy. As a first step, the process will be demonstrated in lab-scale experimentally. Then a theoretical study on a possible Scale-Up and integration into existing industrial plants will follow. The experimental part comprises a material analysis as well as the design, the construction and the operation of the reactors for carbonations and calcination.

The behaviour of CaO/CaCO3-particles is studied by thermodynamic models and thermo-gravimetric experiments. To avoid degradation various metals will be employed for doping. The reaction kinetics of calcination and carbonation is investigated at various gas compositions according to the configuration of real industrial exhaust gases. For every composition of gases appropriate conditions and achievable efficiencies will be determined.

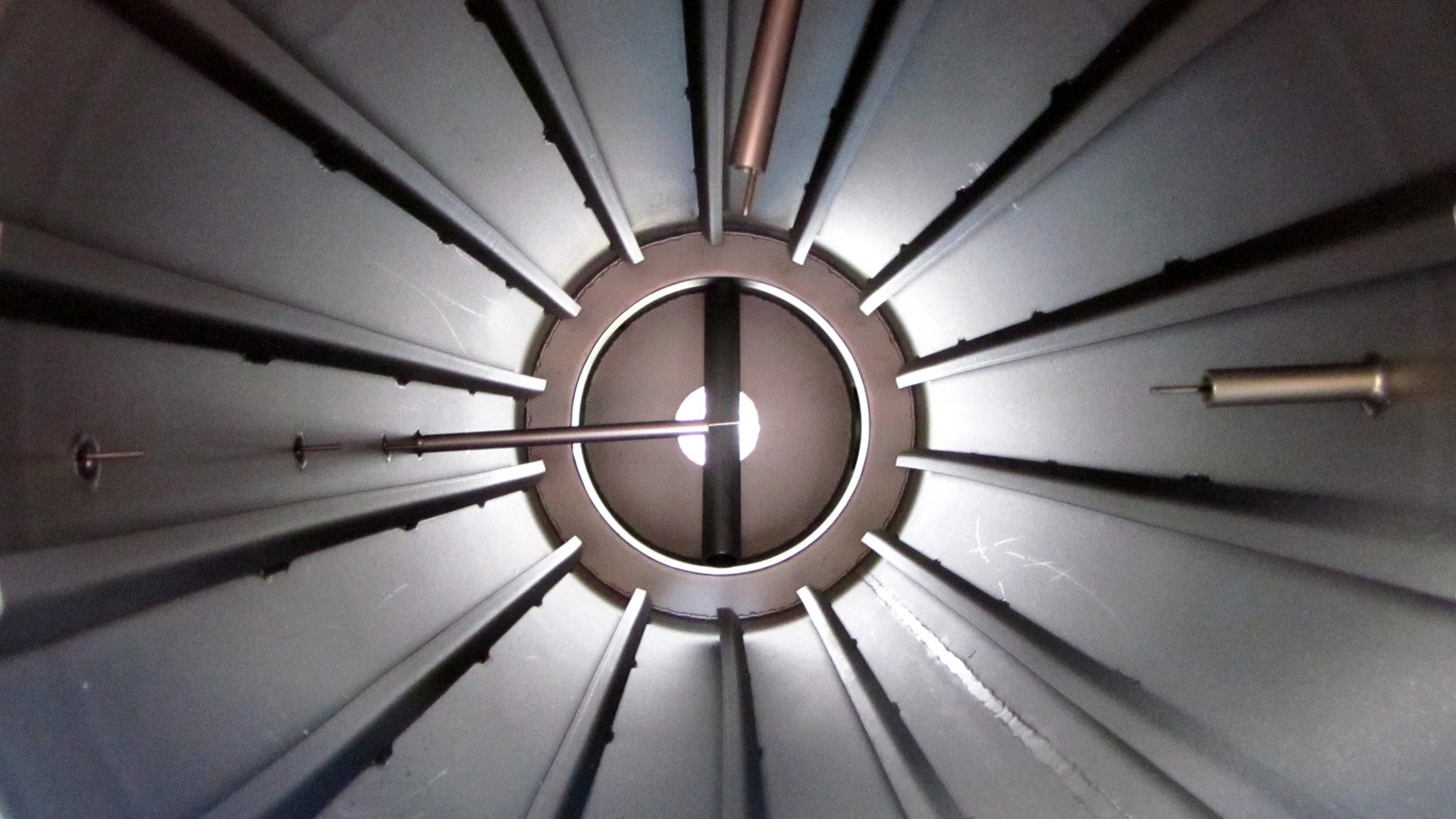

Two reactors are developed. For the endothermic calcination, temperatures of up to 1,000 degrees Celsius are needed. In this reactor, which will be a rotary kiln, limestone particles of various sizes will be heated up to reaction temperature by direct concentrated solar radiation. After that the calcination reaction will be maintained by isothermal heat supply. Particles are completely converted into CaO and leave the reactor via an exit pipe.

The second reactor is for carbonation. Its lay-out is depending of the application considered. If for example the particles are stored in a hot state after calcination and the industrial exhaust-gas employed is hot as well, the reaction enthalpy can be re-used completely. If the particles or the gas are cold, part of the reaction enthalpy must be used for heat-up the raw materials to reaction temperature. If large gas mass flows occur and the reaction enthalpy is not sufficient for heating it up, an external solar heat source is needed.

For the Scale-Up, firstly a study of the application processes will be carried out. Data on various industrial plants will be acquired. Additionally, the possibility to separate application and energy source (24h operation) will be investigated. In a comparative study, the most promising industrial processes for application will be determined. For those, an entire process analysis (flowsheeting) including specification and dimensioning of the components will be carried, which finally is completed by an economic study.

Project | CALyPSOL |

|---|---|

Duration | 1.8.2018 - 31.7.2021 |

Project participants |

|

Funding | Die Landesregierung NRW European Regional Development Fund (ERDF) "Investitionen in Wachstum und Beschäftigung" in the framework of the Leitmarktwettbewerb ErneuerbareEnergien.NRW |