Aero Engine Structures

Our driving force: conserve resources – increase safety

More than ever, the aerospace industry is faced with the question of how to combine cost-effective, efficient and safe air travel with the stringent requirements of sustainability and environmental protection. Alongside constant research into new propulsion concepts, the consistent enhancement of our current aircraft propulsion systems is a key part of the answer.

With its wide-ranging expertise, the research field “Aero Engine Structures” at the Institute of Structures and Design is making a significant contribution to propulsion research at DLR – and has done so for many decades. Innovative types of fibre composite construction methods for engine blades were already being developed in the late 1970s. Since then, new designs and methods have been developed and applied here around the conventional aero engine and also for the propulsion concepts of the future.

Today, we are focusing on the following fields:

- Developing numerical methods that encompass everything from materials and component design to overall system assessment.

- Multidisciplinary design and optimisation of aeronautical propulsion structures, from preliminary designs to detailed analysis.

- Developing construction methods and manufacturing processes for highly stressed structures in every field of aeronautical propulsion, such as compressors, combustion chambers and turbines. This applies to structures made of metal, fibre-reinforced materials (plastics or ceramics) and hybrid designs, including the production, quality assurance and testing of these structures themselves.

Our task is to find an ideal solution for a defined structural requirement, taking into account materials, construction methods and manufacturing processes, and to evaluate component designs from other disciplines or partners.

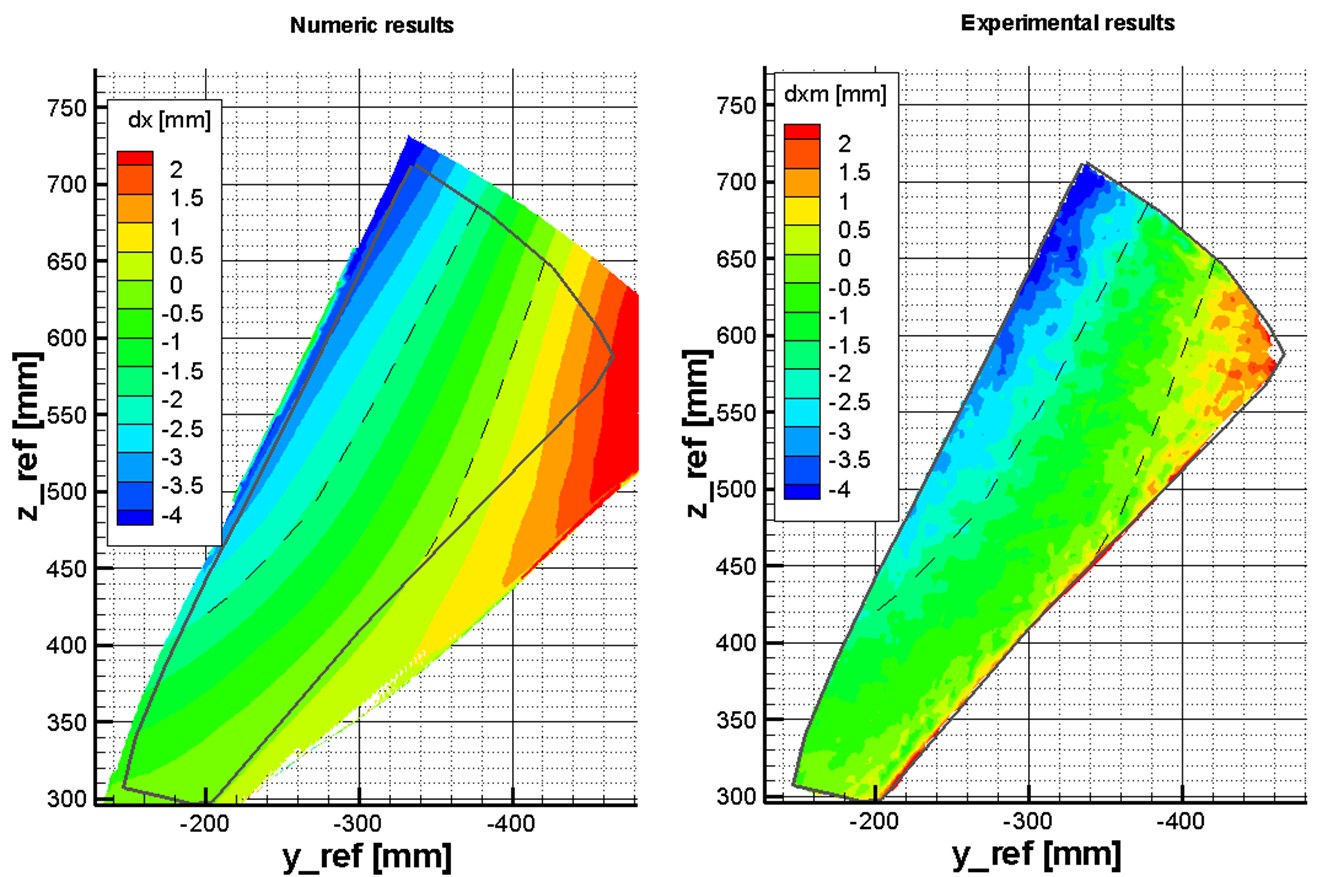

In order to validate and refine our designs and methods, we rely on a sophisticated combination of prediction by means of simulation and the experimental testing of real components.

All our activities, from structural analysis as part of preliminary engine design to the experimental testing of demonstrators, are closely integrated in an internal DLR network of institutes that deal with propulsion research issues. This network also enjoys a high level of visibility beyond DLR and is actively involved in industrial collaborations on both a national and an international scale.

By bringing together all simulation methods across various disciplines, we at DLR are jointly developing the “Virtual Engine Platform”. Going forward, the platform will be used to describe engines and their components as well as the accompanying test benches on the basis of simulation and data in order to provide fast, efficient and reliable answers to all engine-specific questions using digital tools.