DLR Prescreening of new fuel candidates

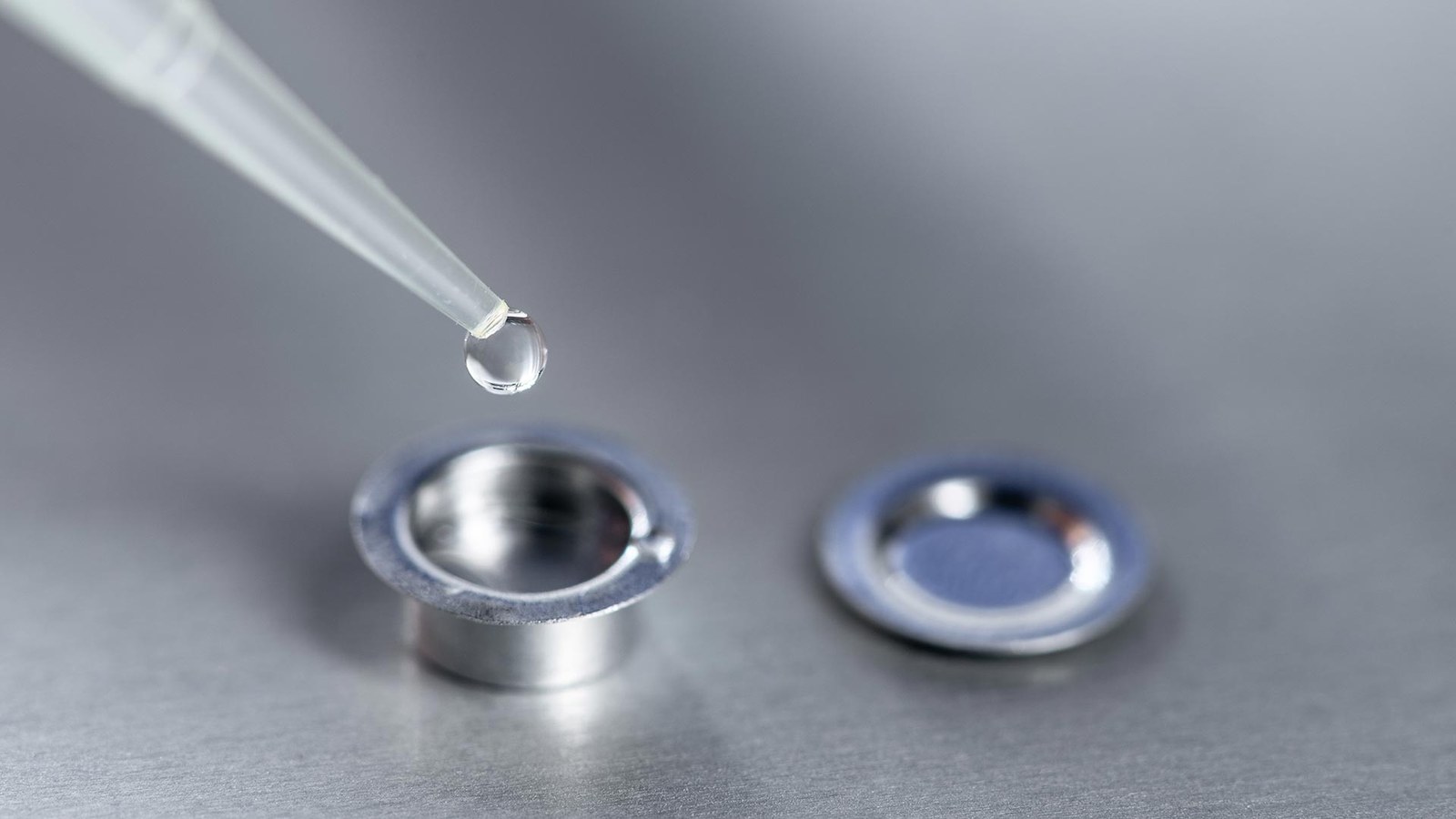

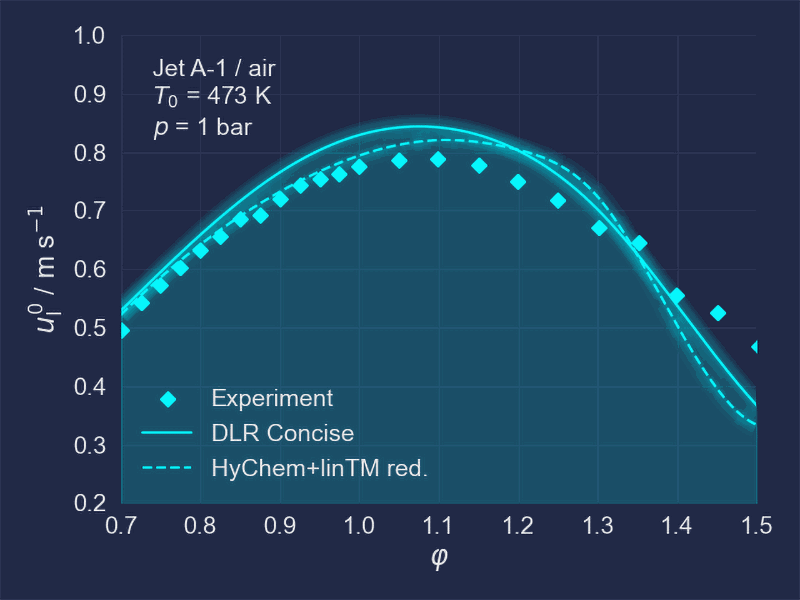

The introduction of alternative fuels for civil aviation is associated with major challenges for manufacturers, even though the demand for sustainable aviation fuels (SAF) is now increasing - not least due to the new legal requirements for blending quotas in the EU and the USA. With prescreening, we offer an opportunity to test and characterise the properties even before approval and with small quantities.