Department Structural and Functional Ceramics

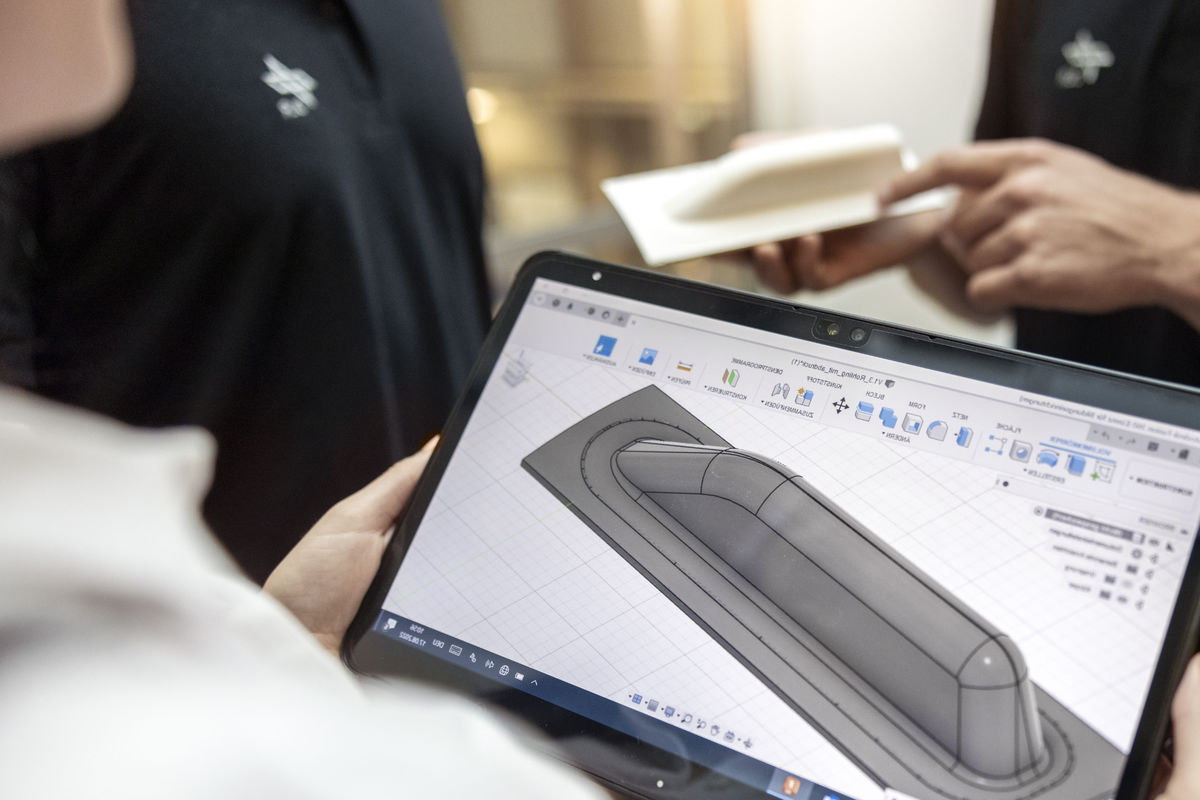

Our R&D portfolio extends from the synthesis of starting materials, semi-finished products, the production of laboratory samples to the production of prototypes and components. This process chain is accompanied by comprehensive and diverse characterization methods. By setting up and developing research data management, the work is digitally integrated in order to accelerate material developments in the future.

Materials and technologies

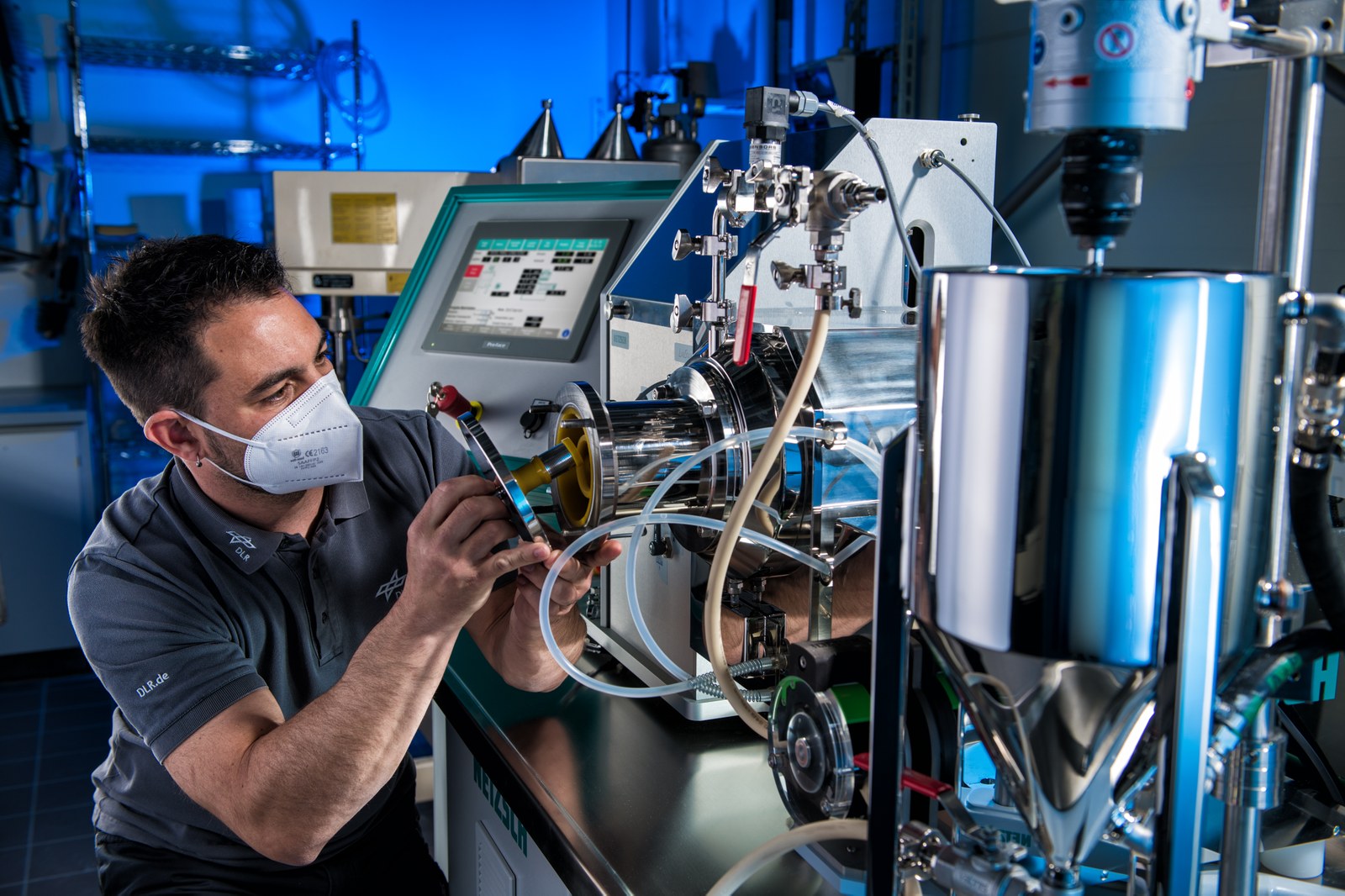

In the OCMC area, we work with powders and fibers based on oxides, which are processed using state-of-the-art equipment such as an agitator ball mill and processed into composite materials using two different processes. Material development is accompanied and accelerated by modern destructive and non-destructive testing methods. The OCMC material we developed under the name WHIPOX® is produced by winding a continuous fiber bundle. Our newly developed OCMC material IFOX® is manufactured using a pressure/vacuum-assisted infusion of ceramic textiles in a closed mold. Depending on the application or shape, components can be manufactured using the optimal process. Both OCMC technologies were or are being brought to industrial maturity and commercialization with the support of DLR technology transfer - WHIPOX by the company WPX-Faserkeramik GmbH (Troisdorf), which was spun off by former colleagues in 2012, and IFOX by the spin-off FOX Composites, which is currently being founded.

In the field of functional ceramics, we deal with oxidic ceramics and the components or coatings made from them, which are used in solar thermal processes at temperatures between 500 and 1500°C. Ceramic particles with high temperature stability and high absorption of sunlight are produced and optimized for point-focusing solar absorbers. So-called redox ceramics are used for high-temperature processes in which particles heated by solar radiation enable targeted chemical reactions, such as the splitting of water into hydrogen and oxygen via cerium oxide. In addition to high-temperature processes, we also develop new materials for heat storage at temperatures of 500 to 1000°C. Here our focus is on cost-effective but sustainable materials, which preferably come from secondary raw materials, e.g. from metal smelting.

Application examples for structural and functional ceramics

The areas of aviation, space travel and energy are the domain of structural and functional ceramics.

Typical areas of application for structural and functional ceramics are:

- Hot gas or exhaust gas routing from gas turbines

- Reusable thermal protection systems for spacecraft

- Thermal insulation and fire protection systems

- Particles and components for the absorption, transport and storage of solar heat

- Particles and components for solar thermochemistry

However, due to the extremely high variability of their material properties and the diverse manufacturing process development options, applications that go far beyond this are conceivable.

If you would like to find out more about our structural and functional ceramics or discuss possible new areas of application, please contact us!

Contact

Dr. rer. nat. Peter Mechnich