Optical Deformation Analysis

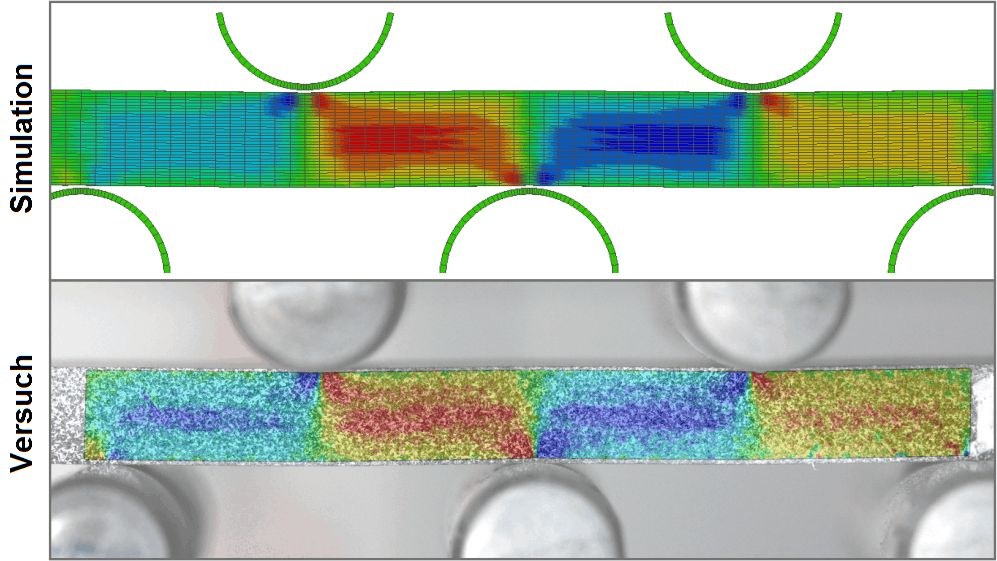

Optical deformation analysis using digital image correlation allows non-contact measurements of strains and displacements both in 2D and 3D.

It can be used in quasi-static as well as dynamic tests to determine the plastic strain of material samples. It directly determines the true strains required for numerical simulations.

Using optical deformation analysis from high-speed film pictures also enables the investigation of dynamic processes in crash/impact tests. Since the optical system operates contactlessly, it has no influence on the test itself and allows a much higher spatial resolution than mechanical sensors.

The system is also very flexible. It can measure both very small (~5 mm) and very large objects (~5 m). The entire system is portable and comprises up to four cameras to capture deformations of complex structures from multiple sides.

LIMESS, TEMA and GOM products are used in the institute.