Urban Rescue – Interdisciplinary, crash-proof structural design considering manufacturing and production aspects

Duration: 2020-2024

In the Urban Rescue project, the most diverse aspects of rotorcraft, such as the eVTOL configuration, were being investigated for airborne urban rescue operations.

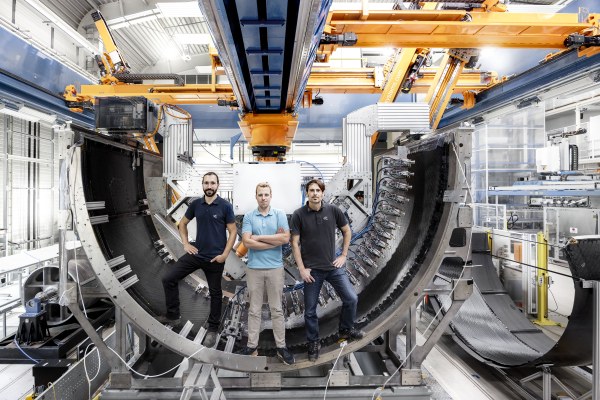

The participating departments of the Institute of Structures and Design in Stuttgart are Component Design and Manufacturing Technologies and Structural Integrity, and at the Augsburg site the Department of Automation and Quality Assurance in Production Technology, which is also the Augsburg Center for Lightweight Production Technology.

Crashworthy eVTOL structural design with a focus on the underbody structure

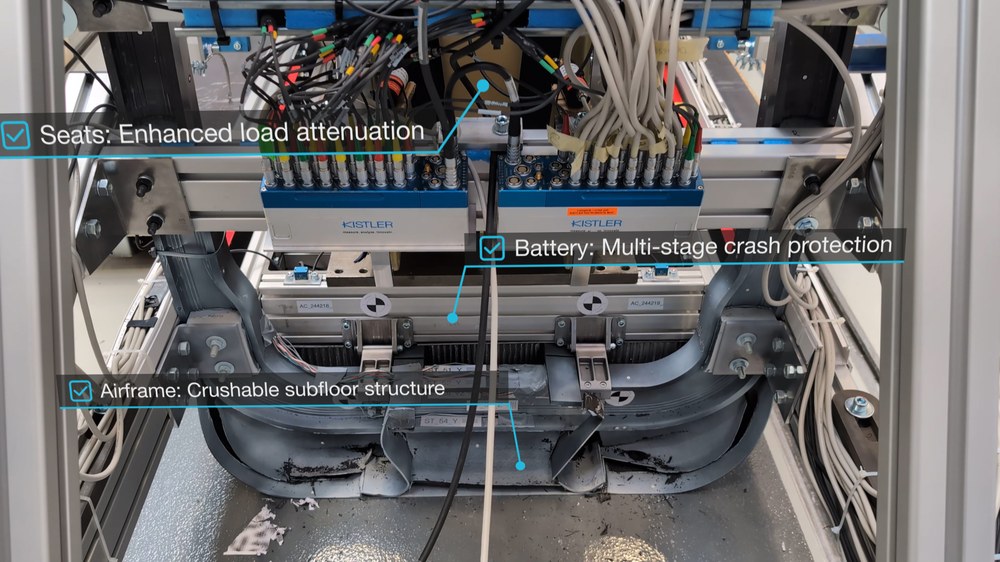

Together, they took an interdisciplinary approach to the structural design of an eVTOL configuration, specifically a two-seater of an airborne emergency doctor deployment vehicle. The design focussed in particular on the underbody structure. This was cooperatively developed, designed and built up to a testable demonstrator in a continuous interdisciplinary exchange. In parallel to the classic structural design, a crashworthy design and the consideration of manufacturing and production aspects were also implemented and analysed in all design phases. The crash design developed includes the airframe structure, safe battery integration and crash-absorbing seats. The aim of linking structural design, crash design and production was to develop an underbody that combines an optimised, crash-safe structural design with innovative production processes. A demonstrator structure of the medical personnel deployment eVTOL, consisting of the central underbody structure and the two main frames, was manufactured at the Center for Lightweight Production Technology in Augsburg in accordance with the results of the design process.

Manufacturing using modern fibre composite technologies

Various fibre-reinforced composite technologies were used to produce the demonstrator structure. Dry fibre placement, resin transfer moulding and the out-of-autoclave prepreg process were used. The processes were selected depending on the respective structural requirements and served to realise reliable, lightweight component production.

Full-scale crash test validates the safety of the eVTOL underbody

The demonstrator was installed at the institute in Stuttgart with a test rig structure, crash-optimised seats and crash-proof battery integration. The crash concept was successfully proven in a full-scale crash test under realistic, combined horizontal-vertical impact conditions (vz = 7.4 m/s, vx = 4.3 m/s).

The findings of the Urban Rescue project will be incorporated into future research projects on the design of eVTOL and helicopter structures.

Video: Project Urban Rescue: Developoing a Crash-Tested eVTOL Demonstrator for Airborne Emergency Response

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.