Institute of Structures and Design

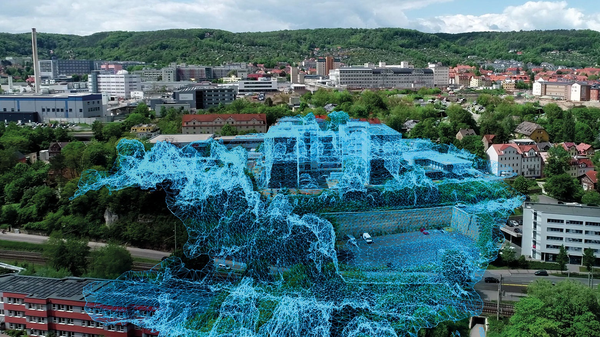

The research activities in the Institute of Structures and Design are concerned with the development and implementation of composite materials with polymer and ceramic matrix in innovative, high performance structures.