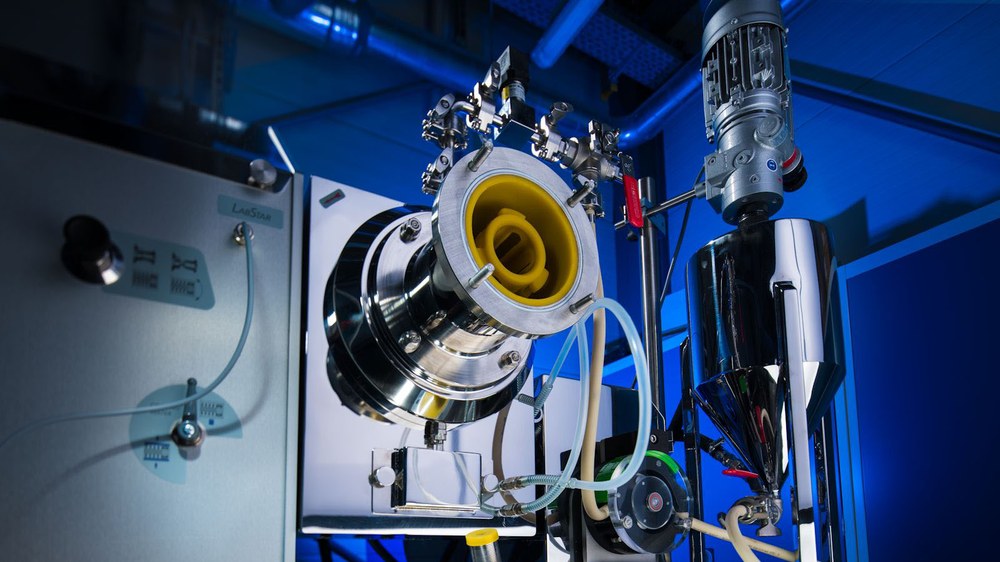

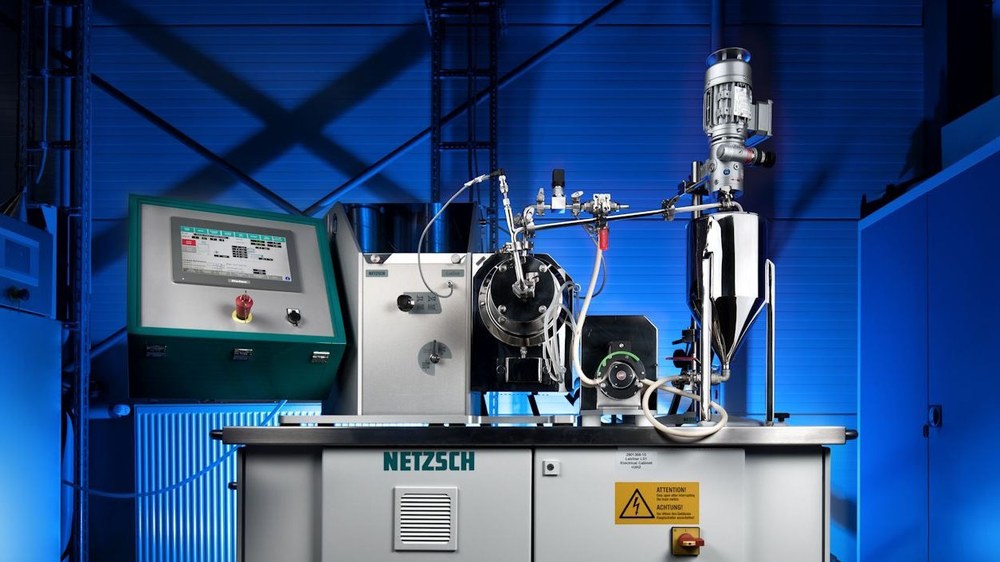

Agitator Ball Mill LabStar

We use the agitator ball mill to develop and produce ceramic particle dispersions, usually called “slips”. Thanks to a modular structure, we have several grinding chamber sizes available made from different materials. For this purpose, grinding balls are specified and selected in diameter and material for the respective application. The RWK thus enables fast, flexible, reproducible and resource-efficient material development from laboratory to prototype scale.

Range of services & functions

The RWK is currently equipped with two grinding chamber linings (polyurethane and zirconium dioxide), the PU version is available in two sizes, so that quantities between approx. 250 and 7000 ml can be processed. For process monitoring, all important parameters such as temperatures and pressures are clearly displayed on a screen, recorded and made available for reading via a digital interface. During development, many parameters can be changed independently of one another and adapted depending on the task. For both process development and quality assurance, parameters can be saved as a recipe and retrieved again when necessary, ensuring reproducible production.

Application examples:

We use the agitator ball mill primarily for the development of ceramic slips for high-temperature stable and damage-tolerant oxide ceramic fiber composite materials (oxCMC) for use in aerospace and energy technology.

System characteristics

- Currently available grinding chamber linings made of PU and ZrO2

- Grinding chamber sizes: 0.24 liters (PU and ZrO2) and 0.66 liters (PU lining only)

- Possible grinding media sizes: approx. 0.5 mm to 2 mm diameter

- Grinding media materials: Al2O3 and ZrO2 (other materials possible)

- Agitator speed 1000 – 4500 rpm

- Measurement data acquisition

- Processing options: single operation, multi-pass operation or batch operation

If you would like to find out more about the possible uses of our system, don't hesitate to contact us!