MFFD – Production Technology for the Thermoplastic Fuselage of Tomorrow

Duration: 2019-2023

The DLR Institute of Structures and Design in Augsburg has completed the production of a full-scale fuselage half-shell for the Clean Sky 2 "Multifunctional Fuselage Demonstrator" (MFFD). Together with the partners Airbus, Premium AEROTEC and Aernnova, DLR delivered the upper shell for the eight-metre-long MFFD demonstrator in July 2023.

The full-scale multifunctional fuselage demonstrator (MFFD) is one of the most important showcase demonstrators within the European Large Passenger Aircraft (LPA) project within Clean Sky 2.

The goal of Large Passenger Aircraft is to demonstrate both best-in-class high maturity technologies and to develop disruptive technologies for '2035+' applications to achieve central ACARE objectives related to the environment, future market requirements and improved competitiveness of the European aerospace industry.

https://www.cleansky.eu/large-passenger-aircraft

In this context, DLR ZLP is involved in the development of advanced laser-based in-situ fibre placement (AFP), as well as the further development of welding technologies - in particular continuous ultrasonic and resistance welding - for dust-free assembly.

A new lightning protection film (Cetex TC1225 LSP) from Toray Industries (Nijverdal, The Netherlands) was used as the first layer for the outer skin to streamline fuselage production through functional integration.

Continuous ultrasonic welding was used to weld the stringers to the in-situ solidified thermoplastic aircraft skin - a world first.

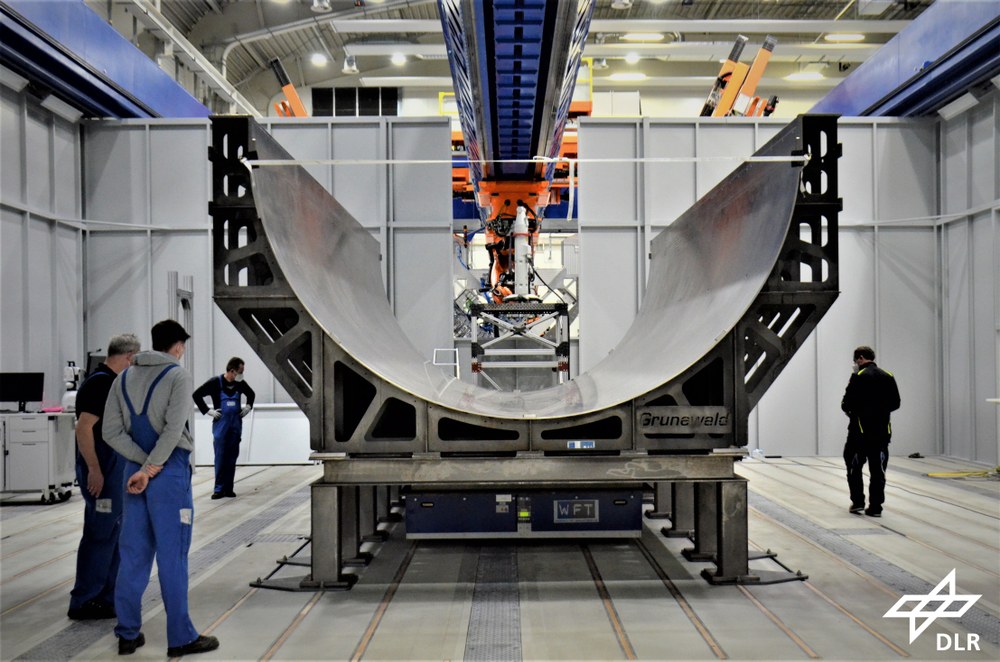

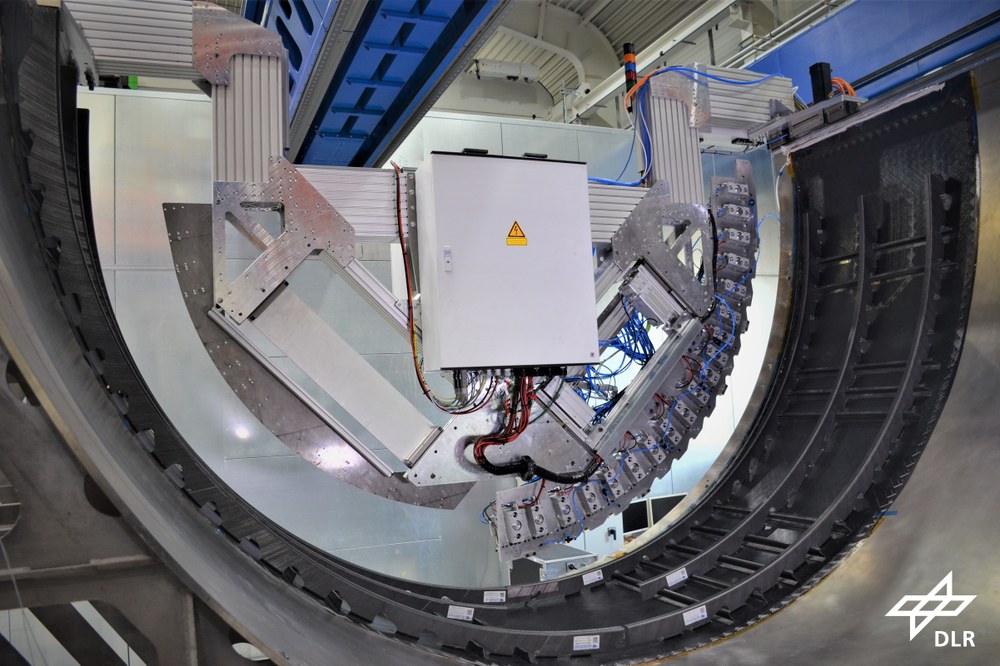

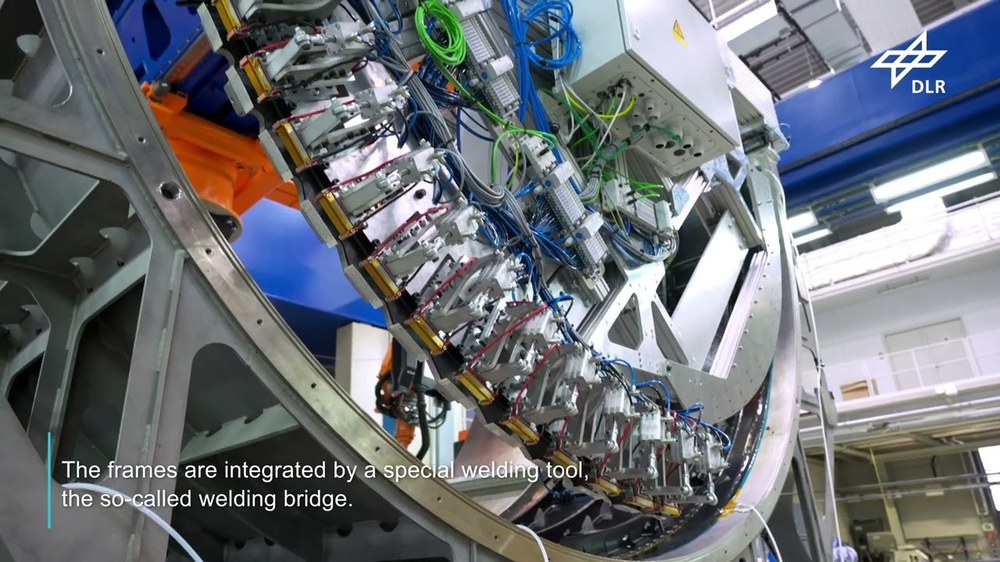

The resistance welding process, which was further developed by DLR together with Premium AEROTEC for the back pressure frame of the AIRBUS A320, joins the C-strings to the skin in the case of the upper shell. For this purpose, a special tool, the "welding bridge", was developed, which is placed on the assembly tool. With this welding technique, the fuselage frames can be joined to the skin within five minutes.

Resistance welding is also used to weld the studs to the stringers and formers in a "robot-on-robot" configuration. This allows precision and accessibility in a very limited workspace.

In this way, DLR is developing the technologies for the sustainable aeronautics of tomorrow.

JEC World

Prior to the final demonstrator, a "test shell" was produced to successfully validate all the thermoplastic composite manufacturing technologies required to produce the MFFD upper shell. The results of this important milestone in this European project were presented at the International Conference on Thermoplastic Composites (ITHEC) in Bremen in October 2022 and received the "Best Paper Award". The project also won the JEC World Innovation Award 2025 in the ‘Aerospace - Parts’ category.

Video: MFFD – Production Technology for the Thermoplastic Fuselage of Tomorrow

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.