DiCADeMa - Digital Cabin Architectures and Design for Manufacturing

DLR

DLR

DLR

Digital cabin architecture: Efficient aircraft assembly with DiCADeMa

Why cabin design is crucial for airlines

Modern airlines no longer decide on an aircraft solely on the basis of range, number of seats or operating costs - because the models from major manufacturers are similar in these areas. Instead, the focus is increasingly on cabin design as a unique selling point to increase passenger experience and customer loyalty.

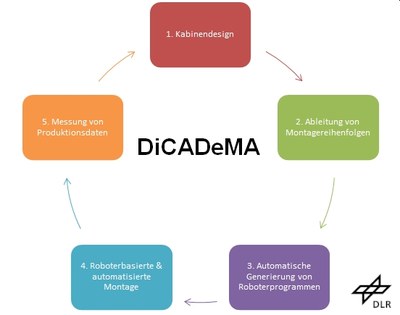

The DLR project DiCADeMa: end-to-end digitalisation of cabin processes

As part of the DiCADeMa (Digital Cabin Architectures and Design for Manufacturing) project, the German Aerospace Centre (DLR) has developed a fully digital process chain - from the design to the automated assembly of cabin components. The aim is to design and produce cabins faster, more flexibly and more economically.

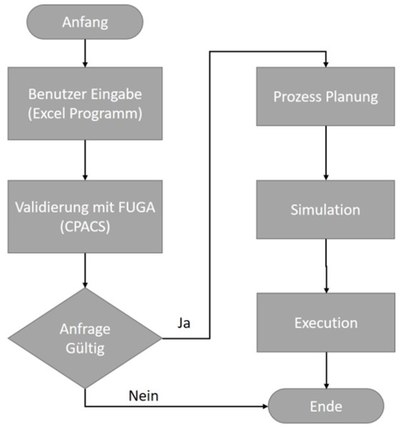

Digital process chain from design to production

By using digital tools and automation technologies, the project demonstrated how cabin design (e.g. hatrack configuration) can be transferred directly to production planning:

- Design phase: Configuration of hatracks and monuments (e.g. galleys)

- Simulation & testing: validation of the cabin configuration (CPACS), calculation of suspension points (FUGA)

- Assembly planning: generation and simulation of the production steps in 3DExperience

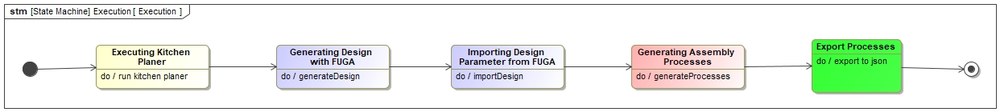

- Execution: Control of a lightweight robot on an AGV for precise marking of the hatrack positions

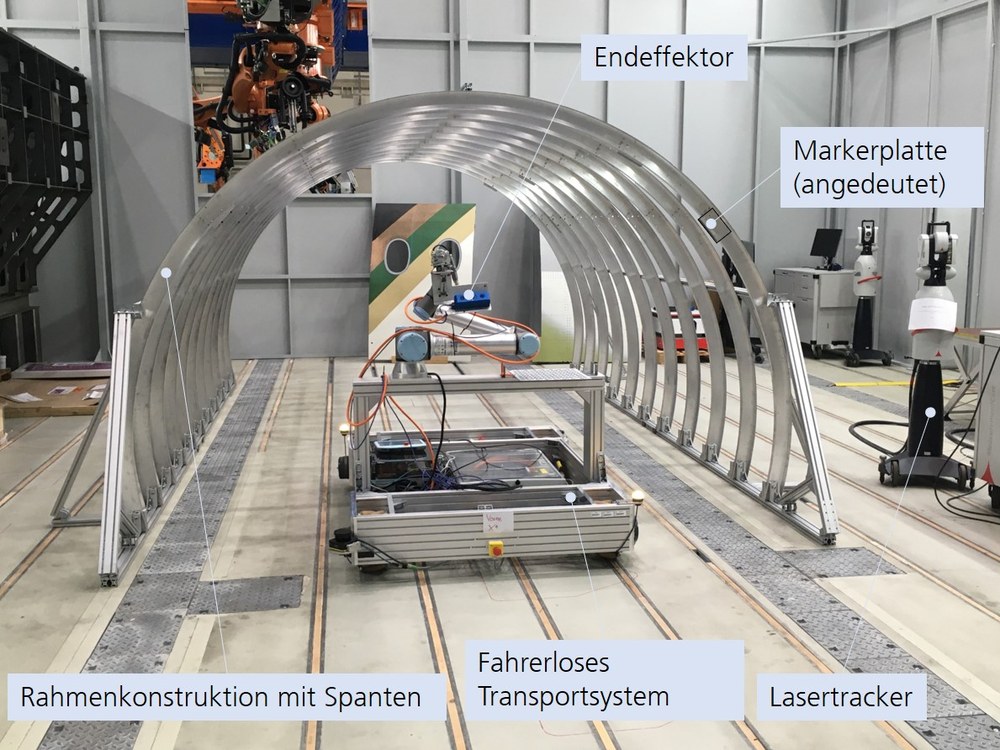

Automated assembly with AGV & lightweight robots

A highlight of the project was the demonstration on the realistic mock-up:

An autonomous guided vehicle (AGV) with a lightweight robot took over the marking of the assembly points. A 3D camera was used to compare CAD data with real structures - this made it possible to mark with an accuracy of approx. 1 mm. The pre-drilling for subsequent assembly can then be carried out by the maintenance personnel.

Advantages for the aviation industry

Digital consistency brings clear advantages:

- Faster cycle times in production

- Reduced production costs

- Increased process reliability and quality

- Customisable cabin concepts ("last-minute customisation")

- Seamless integration into Industry 4.0 environments

These developments secure competitive advantages for the German aviation industry and strengthen Germany as a business location.

Outlook: DiCADeMORe starts in 2026

The follow-up project DiCADeMORe will start in 2026. It is aimed at flexible large-scale production and scaling of processes at factory and supply chain level - with a new use case and extended automation options.

DLR