NATURE – Sustainable Helicopter Structures for Environmentally Friendly Aviation

DLR

DLR

Holistic reduction of CO₂ emissions in aviation

The NATURE (NachhAlTige HUbschRaubErstruktur) research project aims to make a significant contribution to the decarbonisation of the aviation industry, with a focus on the holistic reduction of CO₂ emissions throughout the entire life cycle of helicopter structures.

The project partners consider all phases – from material production to manufacturing technologies, construction methods, operation, and end-of-life processes. This cradle-to-grave approach avoids counterproductive effects that could arise from the isolated optimisation of individual process steps. The aim is to establish sustainable design principles and manufacturing processes that contribute to a significant reduction in the ecological footprint.

Lightweight construction through thin-walled surface structures and innovative joining technologies

The manufacturing of modern CFRP (carbon fibre-reinforced plastic) components for aviation involves several energy-intensive process steps, particularly when drilling and joining to different materials such as metals and adhesives. Furthermore, the resulting structural weight of the final CFRP part depends heavily on the properties and material thickness of the prepreg.

As part of NATURE, the DLR Institute of Structures and Design and the DLR Centre for Lightweight Production Technologies are developing an innovative construction method based on thin-walled shell structures with pseudo-hollow profile stiffeners. This design enables significant weight savings without compromising the mechanical integrity of the structure.

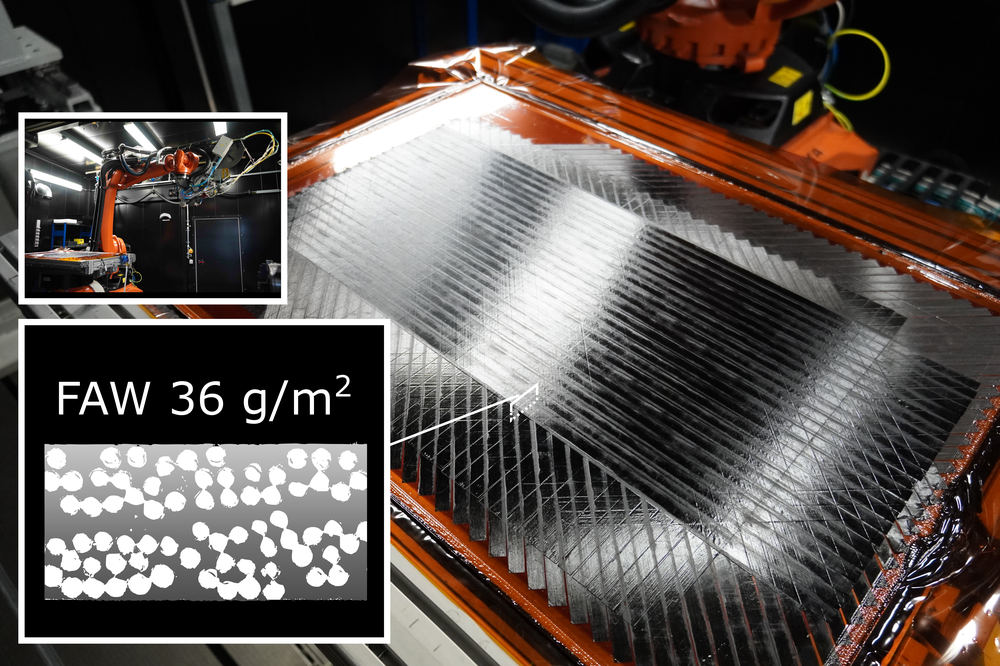

The focus is on the further development of thermoplastic manufacturing technologies in order to make layup and joining processes more efficient. The thermoplastic AFP process is being adapted so that thin, double-curved geometries can be manufactured reliably. In addition, existing thermoplastic joining processes are being evaluated with regard to their suitability for bio-based and recycled materials.

Process automation and material efficiency through SMC technologies

Another field of research in the NATURE project is the automated production of SMC (sheet moulding compound) structures. The use of process simulations is intended to significantly reduce process development time and energy consumption.

This technology enables the economical production of complex structural components that are otherwise made from solid metal. The SMC process can be fully automated and offers a high potential for functional integration. This opens up new possibilities for lightweight construction that offer both ecological and economic advantages.

Interdisciplinary collaboration for sustainable aviation

The NATURE project is funded by the Federal Ministry for Economic Affairs and Climate Protection (BMWK).

The partners involved are:

- Airbus Helicopters

- Fraunhofer IGCV

- Dresden University of Technology (TU Dresden)

- German Aerospace Center (DLR)

Close cooperation between these research institutions and industry partners enables the interdisciplinary development of sustainable aviation technologies. The aim is to establish innovative design and manufacturing methods that make a measurable contribution to reducing CO₂ emissions in aviation.