The chassis has one of the most important tasks in a vehicle, as it must ensure a safe and predictable journey on the road. As a result of increased comfort and the higher speeds at which we travel, chassis concepts have become increasingly complex and heavy. Electromobility now offers the opportunity to break down existing ways of thinking and break new ground in chassis development.

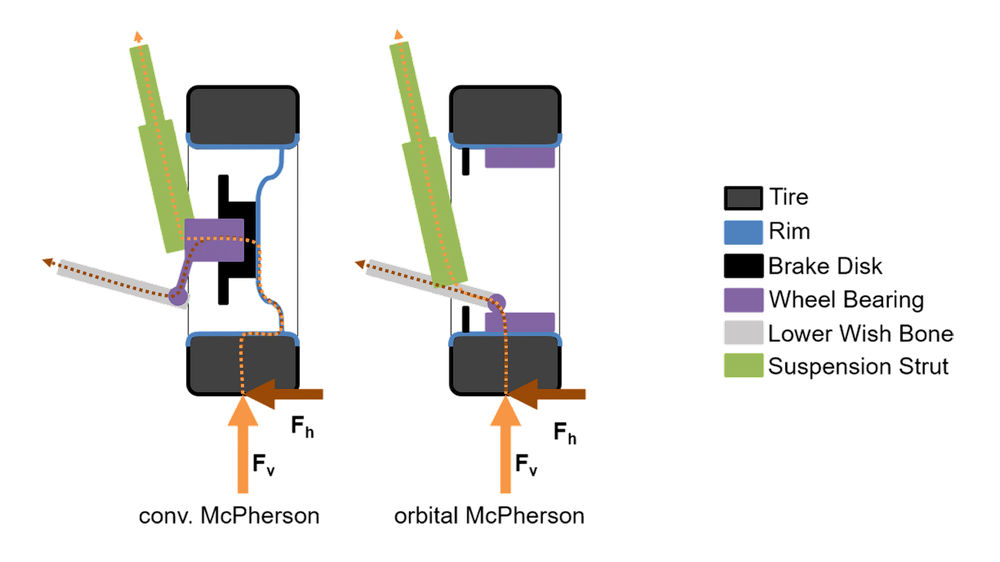

A wheel hub motor offers the possibility of safely designing the vehicle structure independently of the drive. Integrating the electric motor into the wheel rim bed frees up additional installation space for the chassis components. For this purpose, an orbital bearing is used in the rim bed. This makes it possible to transfer the forces to the vehicle structure without detours, close to the wheel contact point.

If all the chassis forces converge at one point, the wheel can be rotated around two axles by means of an active cardan joint. The dual-axle steering actuator therefore not only changes direction, but the wheel can also lean into the bend to absorb higher lateral forces. This promotes stability and safety when cornering or performing evasive manoeuvres.

The third central component of the patented chassis concept is the wheel-guiding transverse leaf spring made of fibre composite plastic. This replaces the steel springs, wishbones and stabiliser bar with a single component, which saves weight and costs. The design of this central safety component is carried out using a semi-automated development process.