The project is funded by the Ministry of Economic Affairs, Innovation, Digitalisation and Energy of the State of North Rhine-Westphalia. To the study

There are currently around 2,700 diesel locomotives still in active shunting service throughout Germany. Some of these locomotives were built before 1972 without emissions regulation. In addition to greenhouse gas emissions, this leads to adverse effects on air quality at the place of use. In addition to a basic feasibility study, the aim of the investigation was to analyse the requirements and possible solutions for retrofitting or building a new vehicle.

Procedure

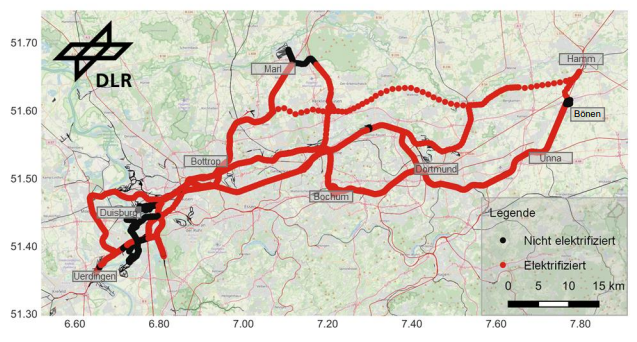

The energy and performance requirements for the fuel cell hybrid drive were determined by analysing the measurement data of a shunting locomotive, type Vossloh Locomotives DE 18, operated by duisport Rail GmbH (dpr). As a result, in addition to the field of application of shunting-heavy mixed traffic, regional line haulage was also identified, most of which was carried out on sections with overhead line availability.

FC hybrid drives (FCH) for the existing MaK G 1206 and Vossloh DE 18 diesel locomotives were dimensioned for both application profile categories. As mainline operation is characterised by high performance requirements, but in the dpr application area this also takes place under overhead contact wire, the suitability of a bi-mode fuel cell locomotive with overhead contact line unit was also included in the investigations (BZH-OL).

Design results

The installation space available on a typical four-axle centre-cab shunting locomotive for the assemblies of a FC-hybrid drivetrain is limited, particularly with regard to the hydrogen that can be carried and thus the achievable range. Particularly in line operation without overhead line availability with FCH drive, refuelling must be carried out more frequently due to the high hydrogen requirement, which must be taken into account when planning locomotive deployment. By integrating an additional overhead line unit for the BZH-OL-BiMode, it is possible to carry additional hydrogen tank capacities due to the smaller dimensions of the BZH unit compared to a pure BZH, which increases the refuelling intervals in shunting operation. Furthermore, the traction energy costs are lower when utilising the electrical energy from the overhead line than when using hydrogen.

The BZH-OL-BiMode variant is best suited for regional lines with a high proportion of overhead lines. On the harbour railway areas of duisport (200 km track length) that are not equipped with overhead lines, a powerful and long-range catenary-independent drive is required in any case. As the shunting-heavy mixed operation does not usually take place under contact wire and a high level of autonomy is required, BZH drives are more suitable here than BiMode vehicles.

Comparison of new construction vs. convertibility of existing locomotives

In principle, it is possible to convert existing locomotives to fuel cell drive, although the cost of conversion varies in individual cases depending on the existing locomotive architecture. However, the greatest flexibility for both the BZH and the BZH-OL is generally offered by a new vehicle optimised for the drive system. Furthermore, the transfer of the conversion to other series was evaluated on the basis of the assessment aspects of range of use, type of power transmission, age of the vehicle, mass, installation space, modular basis, vehicle authorisation, conversion costs and expenditure costs.

Subsequent implementation project

With regard to an implementation project, industry workshops are currently being held with other rail transport companies (RUs) in order to harmonise the duisport-specific requirements for the vehicle design. In order to put together a consortium, exploratory talks are being held in parallel with the rail vehicle industry in order to push ahead with a funded realisation project.

Client

- Duisburger Hafen AG (duisport)

- Funded by the progres.nrw programme of the Ministry of Economic Affairs, Innovation, Digitalisation and Energy of North Rhine-Westphalia (MWIDE)

Project partners

- Duisburger Hafen AG

- DLR Institut für Fahrzeugkonzepte (DLR-FK)

- Zentrum für Brennstoffzellen-Technik (ZBT)

Project duration

- 03/2021 until 12/2022