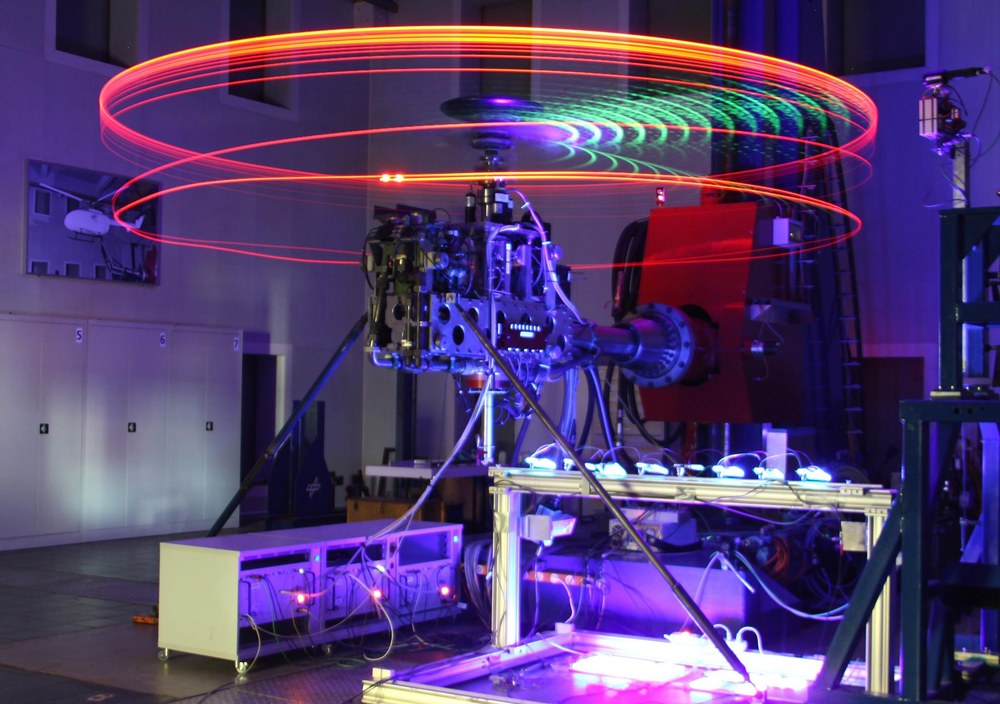

Rotor test rig

The rotor test rig (RVS) operated by the Institute of Flight Systems Technology has a wide range of applications and is an important and globally unique tool. With a total of four different test rigs of different sizes, wind tunnel tests can be carried out with helicopter models, with isolated main and tail rotors, fuselages and overall configurations. The wind tunnel tests with the large models (up to 4.2 m rotor diameter) take place in the DNW-LLF (German-Dutch Wind Tunnels - Large Low-speed Facility) in the Netherlands. Tests with smaller models are carried out in the DNW-NWB (Low-Speed Wind Tunnel Braunschweig).

The rotor test rig group ensures the technical readiness of the various systems. It is also responsible for the further development of the test rigs, prepares the models for the wind tunnel tests and carries them out.

On the one hand, the group consists of employees in the area of mechanical design / production. They are responsible for all tasks relating to the design of new components using CAD systems (Computer-Aided Design and Drafting), including the associated strength calculations, as well as the production of components or production support for external orders.

On the other hand, experts in the field of electronics are responsible for all measurement technology and model instrumentation tasks. A large part of the RVS measurement technology (multi-channel measurement systems, miniature amplifier systems, instrumentation with strain gauges and other sensor types) is developed in-house.

The software required for model control for electric and hydraulic drives, actuators, adjustment devices etc. is also developed by the RVS Group and optimised for its own requirements. Software for data recording is also developed within the group and can therefore be quickly and easily customised to the respective requirements.

Furthermore, research topics in the field of helicopters and rotorcraft, such as new control and regulation technologies for rotors and multi-rotor configurations, are supported by aerospace engineers.

The RVS group also operates an icing test rig, which can be used for the investigation of icing processes on rotors and the rotary testing of de-icing systems. In addition to DLR basic research, the rotor system and flight system technology tasks are usually carried out in close national, European and international co-operation with industry, research institutes and universities.