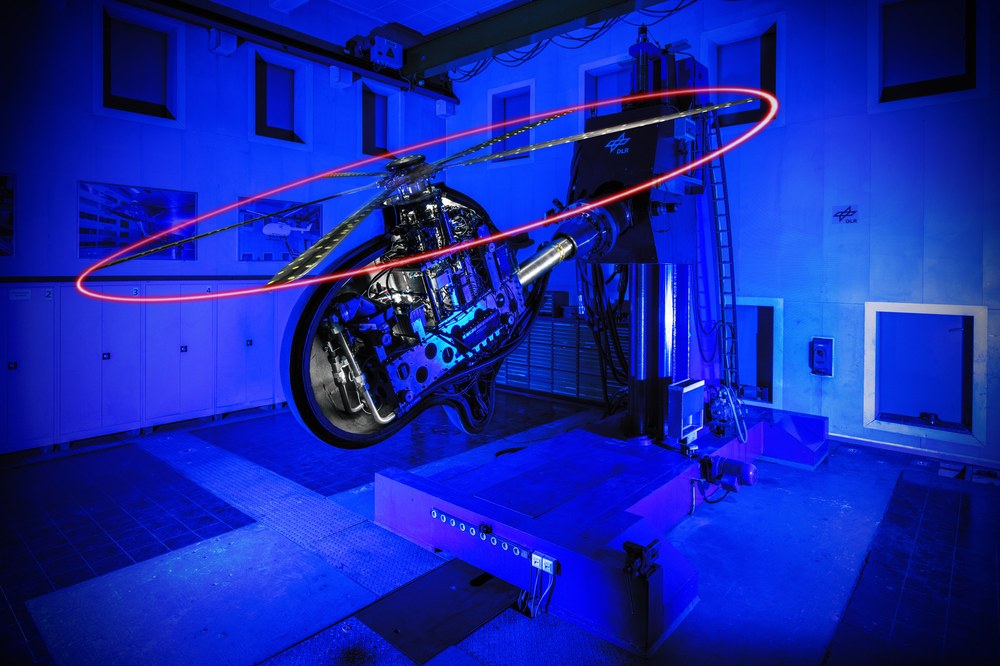

Wind tunnel tests with rotorcraft

Nowadays, modern simulation methods play a key role in the development of aircraft. They make it possible to calculate the aerodynamics and dynamics of the overall system or of individual components even before the individual parts of the device are manufactured. Wind tunnel tests are carried out to support the simulation processes, either to validate the assumptions in a simulation or to gain new insights that lead to extended simulation capabilities by means of modelling.

Wind tunnel tests with rotorcraft are a specialized field with the highest demands on the model, the wind tunnel and the measurement technology. The fast spinning rotors are aerodynamically and often dynamically scaled. They are subject to very high loads and the models must be controlled by a "model pilot" during the tests.

With by now three rotor test rigs for different model and wind tunnel sizes, DLR has been operating highly complex facilities for carrying out wind tunnel tests with rotorcraft for over 50 years. The measurements include loads, deformations and pressure distributions on the fuselage and rotor blades, flow fields in the rotor and noise propagation in space. Main goals are to determine and optimise the performance, vibration and noise behaviour of rotors or complete helicopters and to test new control technologies to support industry and science worldwide, often within the framework of international cooperation.