Flight physics modeling and simulation of rotary-wing aircraft

The modelling and simulation of rotorcraft is an essential area of research that is driven by the highly modular research code MAECOsim®. This code enables precise aeromechanical analyses of classic and innovative rotor configurations and meets the increasing demands for predictive accuracy in aviation. The close co-operation between research institutions and industrial partners promotes advances in rotor technology and supports the development of efficient design concepts.

Modelling and simulation of rotorcraft

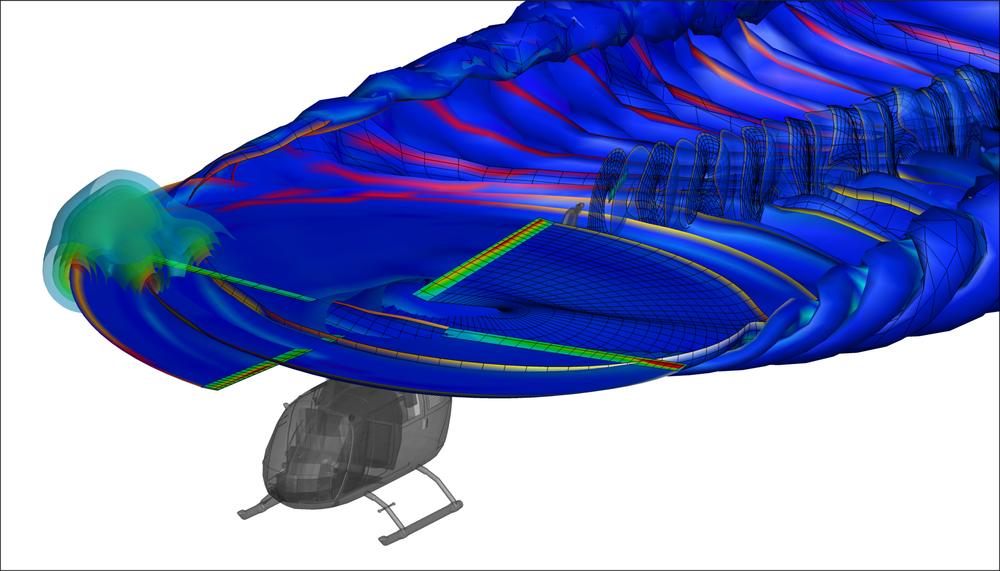

For the simulation and evaluation of rotorcraft, the helicopter department is developing the highly modular MAECOsim® research code, which can be used to aeromechanically simulate classic helicopter configurations with main and tail rotors, as well as unusual configurations with multiple rotors for lift and propulsion and wind turbines. The development, in which several DLR institutes and now also some universities are involved, is being carried out in close co-operation with the industrial partner Airbus Helicopters Deutschland in order to meet the constantly growing demand for high predictive accuracy in the field of simulation and to extend the limits of the current comprehensive simulation of rotorcraft. MAECOsim® implies a variety of disciplines such as flight mechanics, structural dynamics incl. multi-body simulation, aerodynamics, etc. and is designed for a wide range of accuracy for e.g. conceptual and preliminary designs, real-time flight simulators, coupling with high-fidelity methods or detailed aeromechanical simulations.

Rotor technology

When helicopters began to be developed in the first half of the last century, a wide variety of rotor systems and technologies were devised and put into the air. Starting with rotor blades made of wood or metal hinged to the rotor head in order to control the immense forces and moments acting in the rotating system, the hingeless and later the bearingless rotor system of modern rotors with blades made of fibre-reinforced plastics was developed as technological development in the field of materials research progressed. In order to be able to simulate and evaluate the various rotor technologies, models for the different rotor systems are required for aeromechanical simulation which, in addition to the dynamic vibration behaviour of the elastic blades and the primary control of the helicopter, also cover secondary controls such as active rotor control for influencing vibration and/or noise. All models are usually validated with the help of results from tests (wind tunnel, flight test).

Integrated Design of Rotorcraft

Within the integrated design a model generation of a rotorcraft is conducted, in order to meet with specific performance and mission requirements. The Institute of Flight Systems is hereby responsible for two tasks. The first is the flight mechanics modelling, computation and rule-based build-up of an arbitrary virtual configuration inside the processes. This implies the further development of the DLR simulation tools. The second task is the overall architecture and the integration of the several disciplines. Besides of the flight mechanics and modelling the applications also include aerodynamics, propulsion technology (combustion and electric), structural integrity and cabin concepts. The design configurations range from conventional rescue helicopters, over progressive multirotor configurations to highly performant high-speed rotorcraft.