Virtual Design and Testing of Flight Control Systems

The development of aircraft and their associated flight control systems follows a stringent process, often illustrated by the V-Model. The increasing demands for validation and verification of increasingly complex products present growing challenges for the aviation industry.

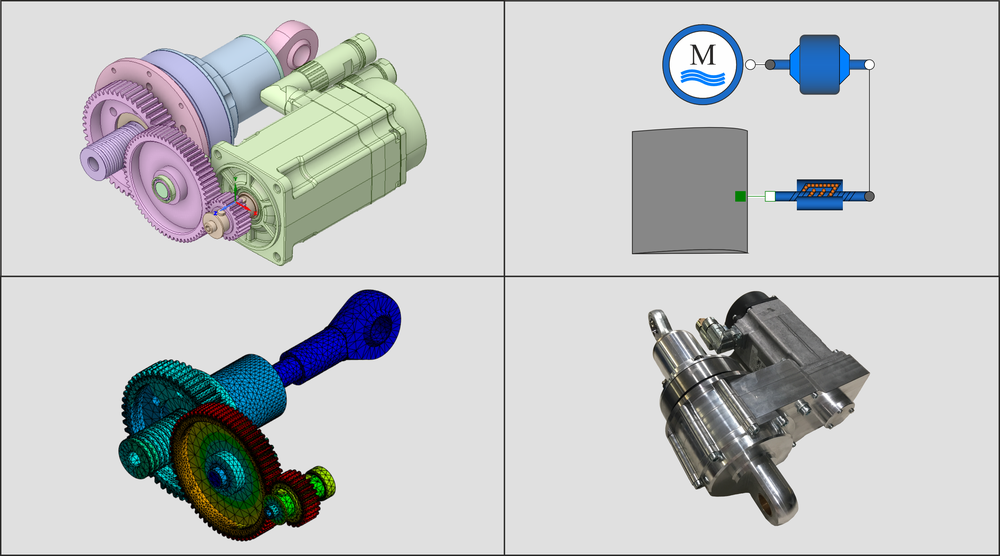

We are working on the seamless integration of virtual design and testing methods into the development process of new aviation technologies to significantly reduce physical testing efforts. The focus areas include flight control and actuation systems, as well as the avionics of modern aircraft. Through model simulations, designs can be optimized, and errors can be identified and addressed early on. For this purpose, we leverage state-of-the-art simulation tools and conduct virtual tests on our real-time simulation platforms. Verification and validation tests are replaced or supplemented by high-quality simulations whenever possible. Hardware-in-the-loop testing on our actuator test benches increases confidence in the simulation results.

Failure Analysis and Tolerance of Electric Drives

The electrification of aviation requires the advancement of increasingly powerful electric drives, including inverters operated by pulse-width modulation. Due to their heightened potential for interference, qualification regulations in aviation must be further developed. The institute investigates the conducted disturbances of high-performance inverter-motor combinations, not only during normal operation but also under electrical fault conditions, as it may be necessary to continue operating the engines despite faults during critical flight phases. To study such fault cases, the institute operates a test stand. Electric motors are also increasingly being used in actuators for controlling control surfaces. The institute explores robust methods for monitoring and diagnosing failures in electromechanical actuators. Fault-tolerant control algorithms enable safe continued operation even after (partial) failures of safety-critical components. These algorithms are developed in virtual simulation environments and validated on test stands.