MiniFix – a Fully 3D-Printed and Highly Adaptable System for Conducting Biological Experiments in Space

- MiniFix is the world's first fully 3D-printed experiment module launched into space

- Already several successful flights on board MAPHEUS sounding rockets

- Biocompostable materials and modular hardware for microgravity research

- The hardware has been scientifically published and categorised internationally as a pioneering technological achievement

- Focus: Space

With MiniFix, the DLR Institute of Aerospace Medicine has developed a new type of experimental system that takes additive manufacturing - i.e. the layer-by-layer construction of components using 3D printing - to a new level in the space context. MiniFix is the world's first fully 3D-printed experimental module that has been developed, qualified and used several times under real space conditions as a complete system with load-bearing structure and mechanics. It has already been used on five successful flights of the MAPHEUS® programme.

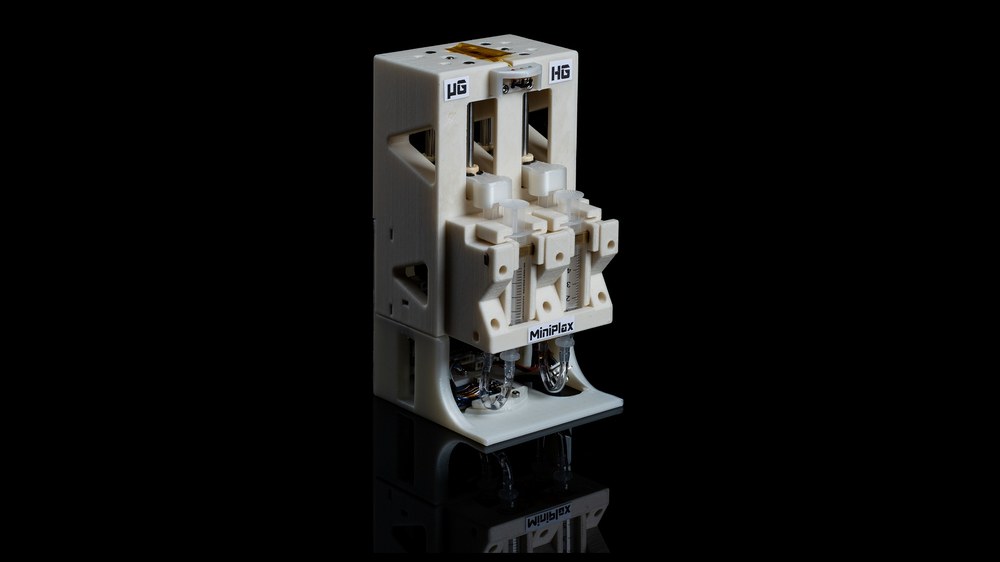

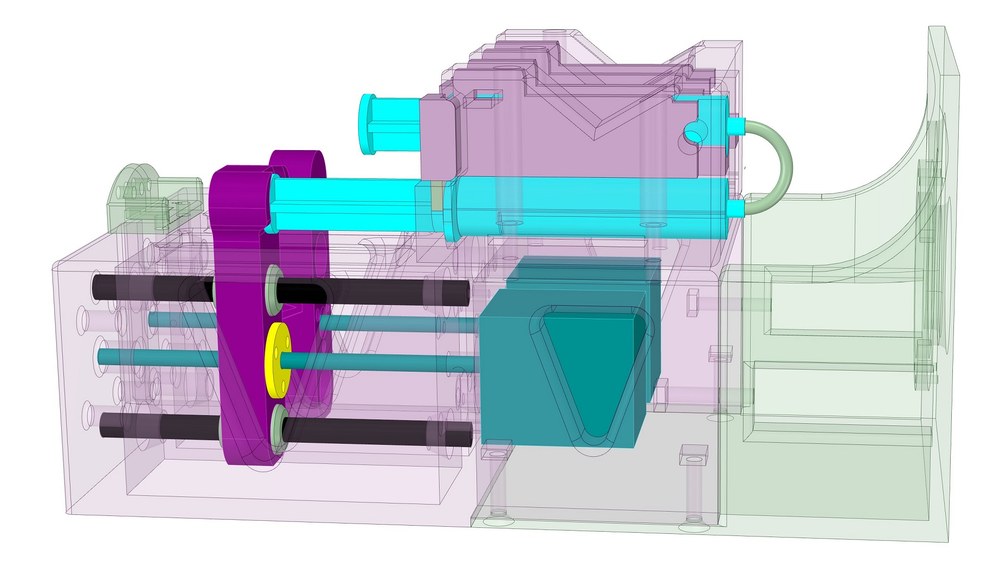

The system is used for the chemical fixation of biological samples during phases of altered gravity - e.g. immediately after take-off (hypergravity) and during microgravity in free fall. The development took place at DLR's Aeromedical FabLab in Cologne-Porz. MiniFix is based on a syringe-driven mechanism that works with high-precision stepper motors (motorised drives with precisely controllable movements), fully 3D-printed structural parts and an open microcontroller architecture. All load-bearing parts were manufactured on standard desktop 3D printers, including components made from GreenTEC Pro - a cold-compostable biopolymer that was used for the first time in a space experiment. Certified medical syringes, whose biocompatibility is covered by industrial standards, are used as sample carriers.

"MiniFix shows that scientifically resilient space hardware can be developed with limited resources, high agility and completely additively manufactured," says Sebastian Feles, technical developer at DLR. "The system has been validated several times under real flight conditions - with over 20 g acceleration, vibrations and extreme temperature changes."

Thanks to its modular design, MiniFix can be adapted to various biological experiments within a few days - e.g. for fixing cells, tissue or plants. Special configurations with integrated lighting have also already been realised. Further development for automated liquid handling for reagents or microfluidic processes is planned. MiniFix is already being used in external research projects, for example in the MiniWeed cooperation project with the University of Adelaide.

The scientific publication „Pioneering the Future of Experimental Space Hardware: MiniFix – a Fully 3D-Printed and Highly Adaptable System for Biological Fixation in Space“ has been published in Microgravity Science and Technology: https://doi.org/10.1007/s12217-025-10178-4