MoSeRoS

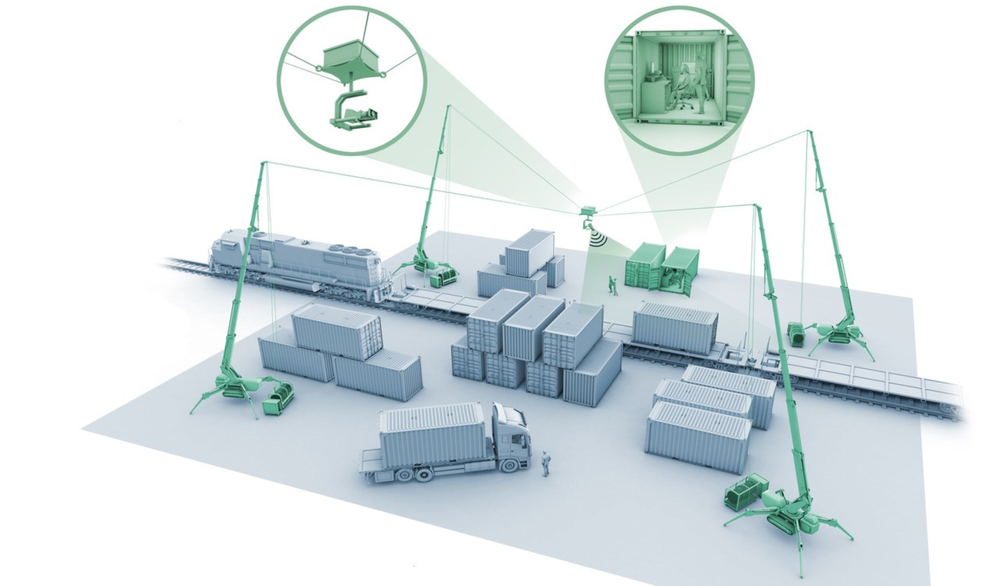

The MoSeRoS system makes it easy to monitor large areas or test new technology. Thanks to the crawler chassis, the cranes can also be used in difficult terrain.

The MoSeRoS system is a mobile, cable-suspended robotic sensor testing platform designed to evaluate and carry various detection systems. It is based on the „Spidercam“ cable camera system known from sport arenas. Unlike fixed installations in arenas, MoSeRoS is fully mobile and can be equipped with more than just simple cameras.

Four mobile cranes, together with four precisely controlled cable winches, create the system's operational workspace. The diagonal of this workspace can span up to 300 meters. The cables carry a highly versatile platform that can be freely maneuvered at a maximum flight height of 14 meters—without downwash and nearly silent. All components of the system are weatherproof, waterproof, and temperature-resistant.

The system is powered by three-phase alternating current (400 V). For autonomous operation, an integrated diesel generator can be used when necessary. To ensure usability in difficult terrain, the cranes are equipped with a crawler drive. Depending on the location, two operators can set up the system within approximately half a day.

Uninterruptible Power Supply and High Payload Capacity

A unique feature of the system is the carrier platform, which has been specially developed for the German Aerospace Center (DLR). It provides a stable power supply (230 V, 2.7 kW) to the attached payload via cables integrated into the winches. Alternatively, battery operation is possible to achieve a greater workspace; however, this requires regular landings for battery replacement.

The system allows payloads of up to 35 kg to be positioned three-dimensionally within the operational workspace. A gimbal ensures that sensitive payloads (up to 15 kg), such as laser emitters or cameras, can be operated stabilized and vibration-free beneath the platform. This enables the testing of sensitive detectors at an early development stage without the need for complex adaptations, such as those required for drone deployment. Additionally, robust computers can be integrated to enable on-platform, sensor-near data processing and reduction.

Data Transmission and System Control

The carrier platform enables data retrieval from installed detection systems via a 10 Gb Ethernet connection. Communication with the ground station is reliable and interference-free, thanks to fiber optic cables woven into the support cables.

The carrier platform enables data retrieval from installed detection systems via a 10 Gb Ethernet connection. Communication with the ground station is reliable and interference-free, thanks to fiber optic cables woven into the support cables.

MoSeRoS at a glance

• Diagonal up to 120 m (394 ft) (300 m / 984 ft in battery operation of the carrier platform)

• Flight altitude up to 14 m (46 ft) (depending on payload)

• Payload of up to 35 kg (77 lbs) (15 kg / 33 lbs vibration-free and motion-decoupled)

• Integrated diesel generator for self-sufficient energy supply in the field

• Downwash-free and low-noise operation

• Fast and robust communication with carrier platform (10 GbE fiber optic)

• Manual and programmable control possible

• Weatherproof and robust against temperature fluctuations

• No ascent permit required for Germany

• Transport using two 20-foot sea containers

• Can be set up in less than half a day (depending on terrain and infrastructure)