How hydrogen becomes a system-relevant factor

Fichtner IT Consulting

- In the SYSTOGEN100 research project, scientists from the Institute of Networked Energy Systems are simulating the interplay between electrolyser and energy system in several field test scenarios.

- As part of the project, a simulation model has been developed that considers components, operating strategies, weather data, and various other framework conditions together in order to optimise the design and operation of electrolysers.

- The goal is to store surplus energy from wind and solar power in the future under economically attractive conditions as hydrogen, rather than throttling back plants during peak periods.

- Focus: Hydrogen, Energy management, System modelling

In theory, it sounds simple: renewable energies supply us with electricity, and excess energy is used to produce hydrogen. And when our energy demand cannot be met by sun and wind alone, we use this "green" hydrogen to generate electricity again. However, in practice, it's more complicated. Electrolysers need to be dynamically controlled and integrated into existing energy systems to avoid local grid bottlenecks. This requires complex control strategies and system management. Additionally, they must be economically attractive and integrated into markets for electricity, balancing energy, and hydrogen to create investment incentives. Therefore, the system and electrolyser must be carefully matched. Against this background, the Institute of Networked Energy Systems has developed a simulation model within the SYSTOGEN100 research project that considers components, operating strategies, weather data, and various other framework conditions together. Results of this method will be presented by the institute at the H2Giga final conference in Frankfurt/Main on 2 and 3 July 2025.

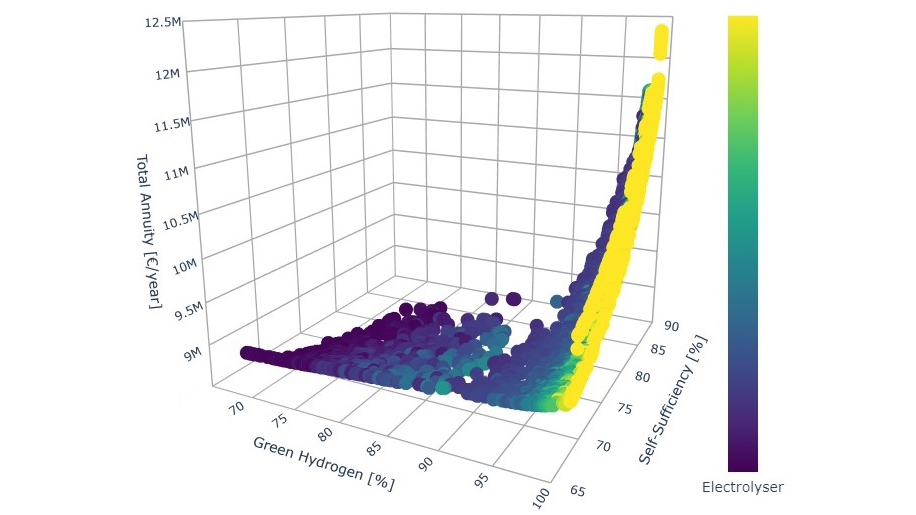

"Our results on design optimisation can be displayed as 3D plots," explains Rabea Weil, SYSTOGEN100 project leader at the Institute of Networked Energy Systems. "This allows us to illustrate directly how measurable key performance indicators – such as economic viability, hydrogen production costs, or self-sufficiency – relate to each other." The freely selectable parameters form a three-dimensional Pareto front from dozens of data points, each representing possible solution options. Simplified, there is no 'right' or 'wrong' – "it's about making an individual selection for the design, such as the size of a planned electrolyser in relation to the available investment volume". This analysis is valuable, for example, for municipal utilities or wind farm operators who plan to store high surpluses from wind and solar energy in hydrogen in the future – instead of curtailing the plants during peak times.

To analyse optimised energy systems with electrolysers, fluctuating renewable energies, and variable demand in a realistic way, the project team around Weil has three fictional use-case scenarios in the Heide region of Schleswig-Holstein available, as well as a real use-case at the Berufsbildungszentrum Heide. The first use-case scenario assumes an off-grid system that aims to produce as much green hydrogen as possible from wind and PV parks. Here, an energy system with electrolyser and battery is optimised aiming for maximum self-consumption of renewable energies but must also be economically viable.

Two further use-case scenarios include a connection to the power grid and various consumers for electricity and hydrogen. One scenario also includes feeding hydrogen into the grid, with a stronger focus on economic viability. "Here, we are looking for the optimal design of the electrolyser and battery, as well as a hydrogen storage system," says Weil. The use of the electrolyser should be grid-friendly in all scenarios, enabling maximum self-consumption and avoiding curtailment.

As soon as the optimal designs have been defined for all three variants, they will be tested using the operation optimisation model MTRESS (Model Template for Renewable Energy Supply Systems) developed at the institute. Here, the scenarios are exposed to different financial and regulatory framework conditions developed and provided by other project participants. "Based on this simulation, we can then assess how well the energy systems perform under various conditions, for example in an event of a dark doldrum," explains Weil.

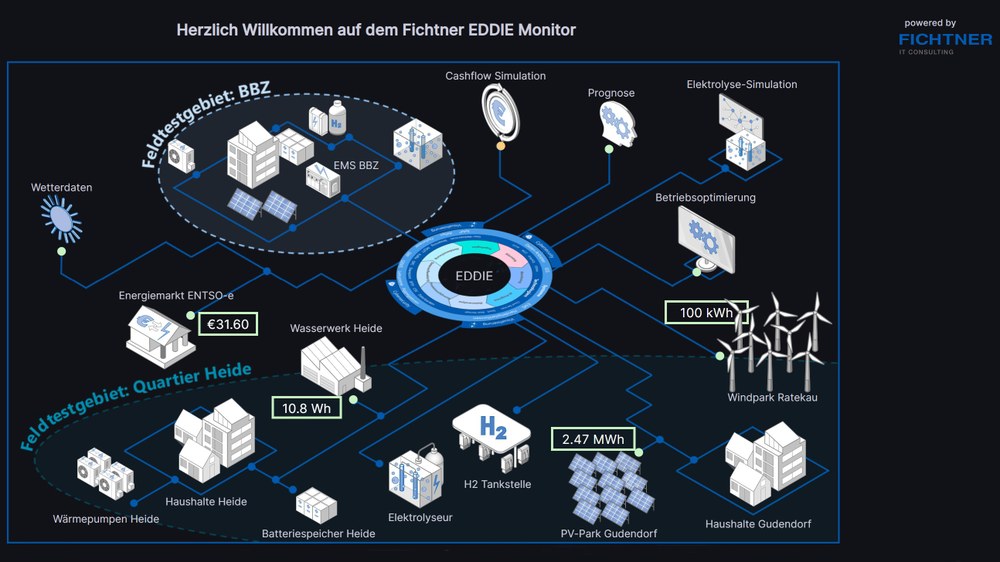

How the simulation can be applied in practice is being tested in parallel in the fourth scenario, a use-case at the Berufsbildungszentrum "Lernort Heide". This includes a PV system on the school building and an electrolyser with fuel cell. The goal is to supply the electrolyser with control commands based on real data and thus test the live application of operation optimisation. The integration platform EDDIE ("Energy Data Digitalisation – Integration – Empowerment") from the Fichtner Group, which is involved in the project, plays a role here, as Weil explains: "Using this tool, we get direct access to weather data and feed-in forecasts for the PV system. From this, we create 24-hour schedules with which we can adapt the operation of the electrolyser to the current conditions on a daily basis. In this way, we can optimise the operation of the electrolyser – and ultimately its behaviour as part of the energy system – step by step.“

More information: