Assembly technologies

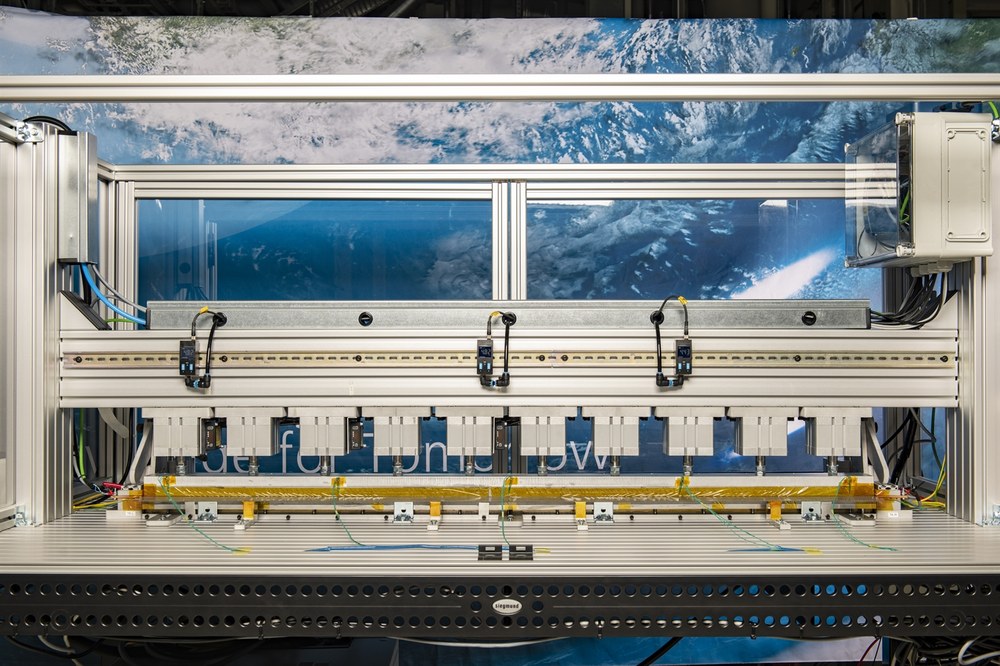

How can aerospace components be assembled automatically? The Assembly and Joining Technologies Group develops automated solutions for this purpose. The portfolio includes, for example, clamping technologies, fixture development, end effector development, robot process and automation technology, tolerance and variant management and overall process control.

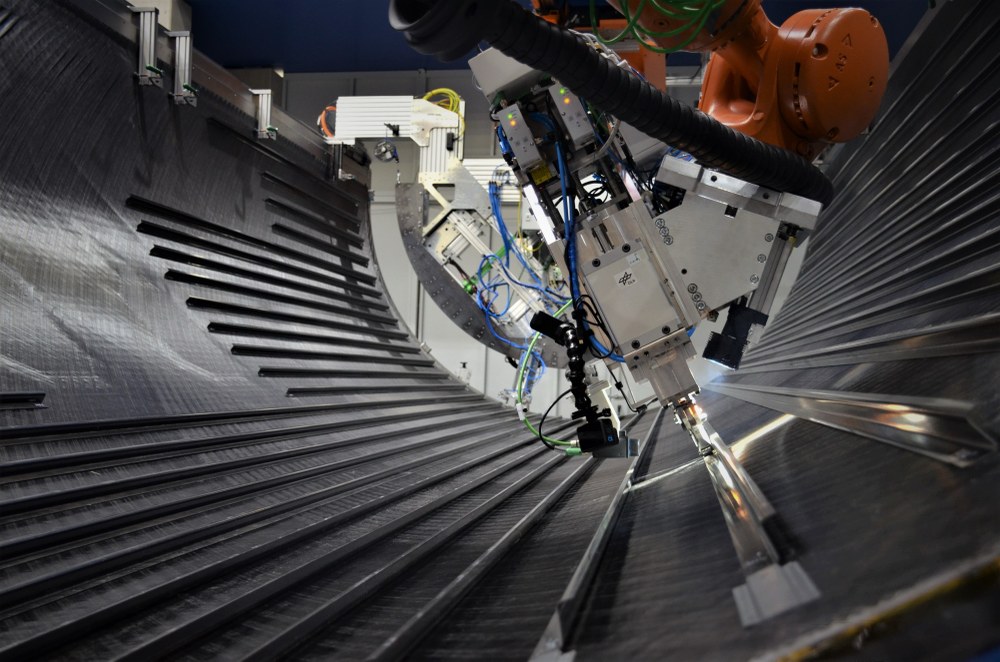

Joining technologies

The focus is on the welding of thermoplastic fibre composite components, which offer the possibility of converting assembly sequences, e.g. in aircraft production. In the metal sector, the systems are currently only integrated after the structure has been assembled, as these can be damaged by the chips produced. However, this sequence has the disadvantage that limited accessibility makes assembly considerably more difficult.

For welding the thermoplastic components, we develop industrial solutions that enable automated welding processes. Both static and continuous electric resistance welding and static and continuous ultrasonic welding are used.

Other key areas of research are riveting, bonding and shimming of component assemblies made of fibre-reinforced plastics or metal.

In the field of bonding and shimming, we are working on the automated preparation and inspection of joining surfaces and process-reliable application for various applications.

For all joining processes, we pay particular attention to inline process monitoring, which makes it possible to make a statement about the quality of the joint during the process.

Process optimisation

In addition to assembly and joining technologies, the characterisation of the overall process is one of the focal points of our research. The main focus here is on the optimisation of assembly sequences in order to save effort and costs.

Construction

Project-related development, design and procurement of mechanical engineering components for the realisation of automated production processes.

DLR

DLR

DLR