Innovative robot platforms for the production and joining of thermoplastic aerostructures

DLR

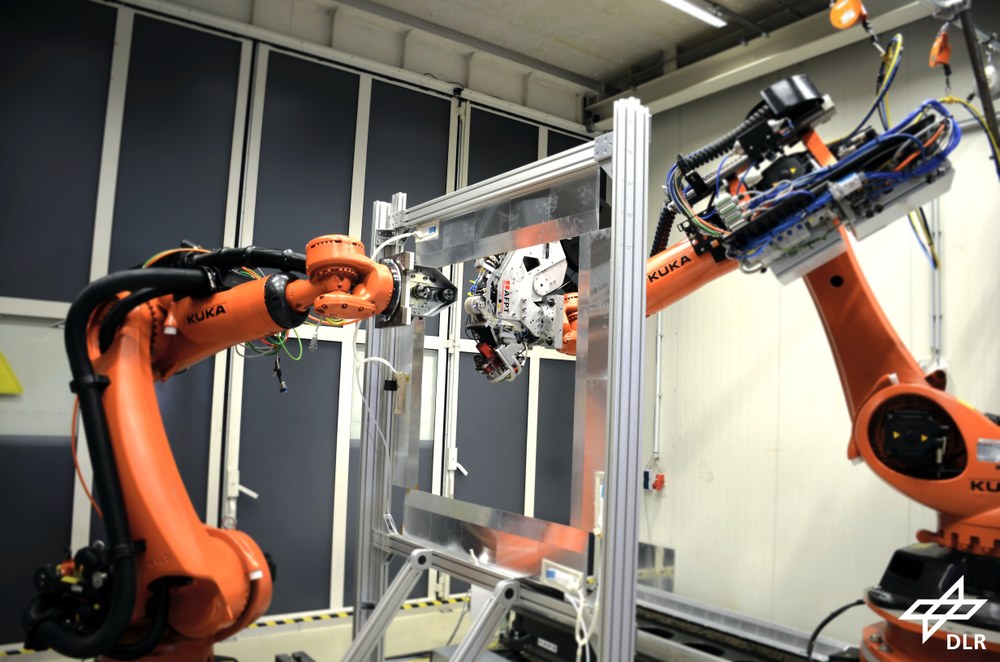

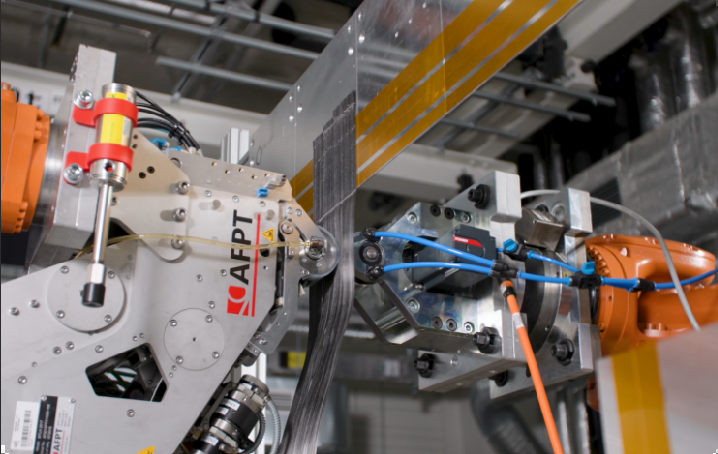

As part of the project, new manufacturing processes are being developed for the aerospace industry using industrial robots. The aim is to reduce the complexity of fixtures and moulds, thereby reducing costs and increasing design flexibility for aerospace structural parts. Multi-robot setups are used to manufacture and weld complex curved carbon fibre reinforced plastics using automatic fibre placement and ultrasonic welding. Robot accuracy is improved through dynamic parameter identification, modelling and real-time error compensation to meet the requirements of multi-robot manufacturing.

Part of this unique approach is the international collaboration between the National Research Council of Canada and the German Aerospace Centre (DLR). DLR's own Centre for Lightweight Production Technology (ZLP) will support the research with its extensive expertise in structural components for aircraft, thermoplastic CFPR manufacturing processes and automated offline robot programming. The National Research Centre will contribute its complex robot compensation models to improve the robot hardware.

Innovative Robotic Platforms: Dual-Robot AFP and Welding of Thermoplastic CFRPs

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

DLR