Development of a holistic Design for Circularity (DfC) methodology for the circular design of vehicle components

As part of the MaTiC-M project, the research project is developing a holistic DfC methodology for analysing and designing vehicle components in a circular way. The basis is the evaluation of economic, ecological and strategic criteria, taking into account technical feasibility. The methodology enables the transparency of different circular paths and serves as a decision-making tool for evaluating the influence of design decisions on circularity.

Uniqueness of the service

The uniqueness of the developed methodology lies in its holistic trade-off approach. By simultaneously considering economic, ecological, strategic and technical aspects, it enables an integrated evaluation of design decisions. Users can compare criteria and set priorities, allowing the methodology to be flexibly adapted to specific development goals, products or sustainability strategies.

Technical details (methodology)

The methodology combines a data-based evaluation logic with a digital analysis and decision support tool. A holistic trade-off analysis makes the impacts transparent. Among other things, LCA, LCC, circularity, joining technologies, material and alloy compatibility for recycling processes and material criticality are analysed. At the same time, hotspots that are crucial for the recyclability of a component are identified at the technical design level.

The integrated matching process makes it possible to output alternative design options - such as material selection or joining technologies - based on the defined user priorities.

Use cases implemented

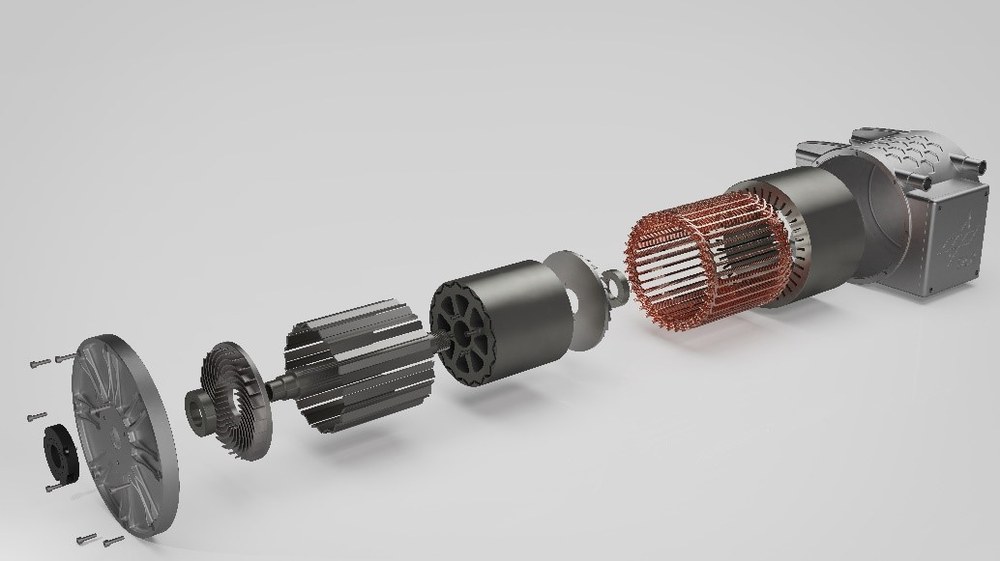

The methodology was developed using several products, including the battery housing of an electric vehicle and an electric drive motor. Additional use cases from the aerospace and energy sectors were also included to ensure transferability to different requirements, materials, joining technologies and utilisation scenarios. This diversity strengthens the robustness of the methodology and ensures its applicability to a wide range of industrial contexts.

Collaboration and industry

The methodology was developed using several products, including the battery housing of an electric vehicle and an electric drive motor. Additional use cases from the aerospace and energy sectors were also included to ensure transferability to different requirements, materials, joining technologies and utilisation scenarios. This diversity strengthens the robustness of the methodology and ensures its applicability to a wide range of industrial contexts.