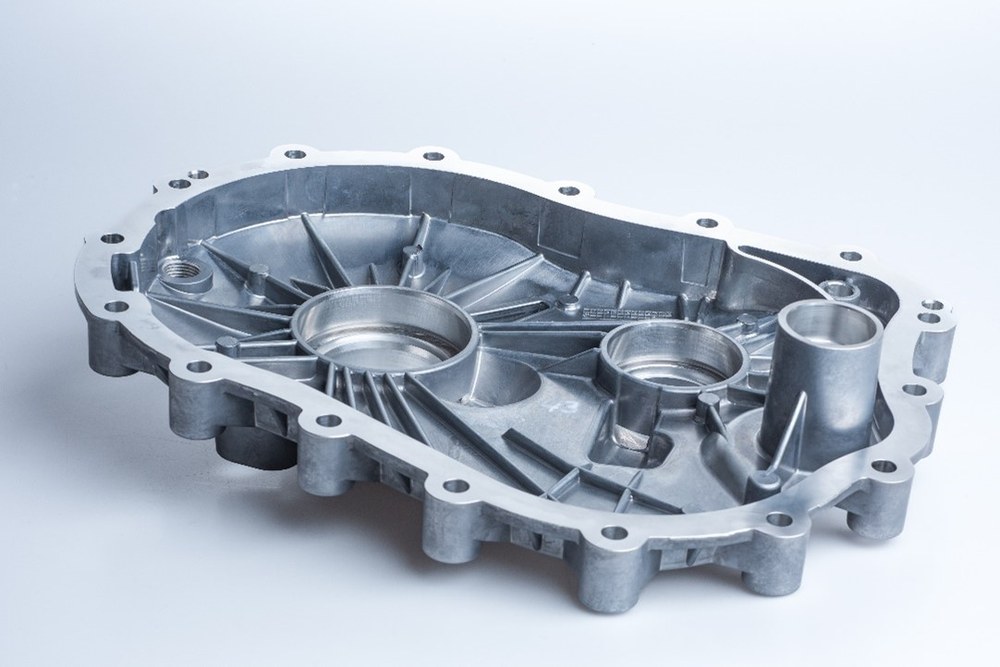

Innovative die-cast components and technologies for vehicle applications

The institute offers comprehensive research and development services for the efficient design of particularly lightweight cast components, for example for electromobility and vehicle structures.

The focus here is on lightweight structures made of aluminium and magnesium alloys, where we contribute to reducing weight, CO₂ emissions and manufacturing costs through targeted design and process design. Our work generally results in components with the same function that weigh significantly less than comparable state-of-the-art cast components.

Our methods combine engineering analyses with practical implementation, from the early concept phase to the prototype. In this way, we support industrial partners in utilising the advantages of modern die-casting technologies particularly efficiently and integrating them into electric drive systems and chassis structures, for example.

Innovative design methodology

With our specially developed design method for complex cast components, we combine proven lightweight construction principles with a systematic, force flow-orientated design.

Instead of conventional approaches, in which bearing points and functional elements are first defined and then covered with close-fitting enveloping surfaces, we rely on an upstream analysis of the main operating loads.

A detailed load analysis contributes to the optimisation of the component at an early concept phase - a decisive step in order to use material specifically where it is structurally effective. Only once the analysis has been completed is the concept transferred to a CAD design, guaranteeing a design that is appropriate for the flow of forces.

Analysis and simulation

In a further analysis step, we visualise the mechanical load paths within the component. This allows us to identify the main loads, for example in the drive and recuperation phases, and derive suitable structural principles.

This approach allows design flaws to be recognised and avoided at an early stage. The result is improved material utilisation, increased component performance and reduced mass without compromising on mechanical stability.

Technological advantages and fields of application

The use of this method results in lightweight components with high efficiency potential for a wide range of applications, e.g. in electromobility - from housings for electric drives to load-bearing chassis components.

The advantages at a glance:

- Weight reduction through optimised geometries and targeted use of materials

- Increased strength and service life due to reduced stress levels

- Improved casting quality thanks to uniform wall thicknesses and minimised material accumulation

- Process stability and cost efficiency due to reduced susceptibility to defects

Our services

We support industrial and research partners in all phases of casting development from concept analysis to production-ready implementation. This includes

- Force flow analysis and visualisation of the main operating loads

- Derivation and application of load-optimised design principles

- Detailed and production-orientated design taking into account

- Topology and structural optimisation

- Validation through simulation and component-specific test procedures

Contact

Elmar Beeh