Icing and de-icing in Aviation Research

Ice formation on aircraft poses a significant safety risk – for both helicopters and fixed-wing aircraft. It can severely affect aerodynamics, controllability, and system functionality. To address these challenges, the DLR Institute of Flight Systems develops and tests innovative icing and de-icing technologies. In this field, the Institute is conducting research into practical solutions for the detection, analysis, and removal of ice.

Monitoring aircraft icing during flight

Icing of fixed-wing aircraft – especially caused by supercooled large droplets (SLD) – can pose a significant safety risk in flight. For years, the Institute of Flight Systems has been involved in international research on this topic and has explored various approaches for simulating and analysing flight dynamics under icing conditions affecting different aircraft surfaces.

Most recently, the institute coordinated the EU project SENS4ICE (SENSors and certifiable hybrid architectures for safer aviation in ICing Environment), in which novel technologies for the detection of SLD were investigated in collaboration with 16 other project partners. As part of this effort, the institute developed an innovative aircraft-based approach for ice detection: a performance-monitoring software capable of reliably identifying icing on the aircraft in an indirect manner. This approach was successfully demonstrated in flight tests and is considered a promising technology by both industry and certification authorities.

De-icing of rotor blades

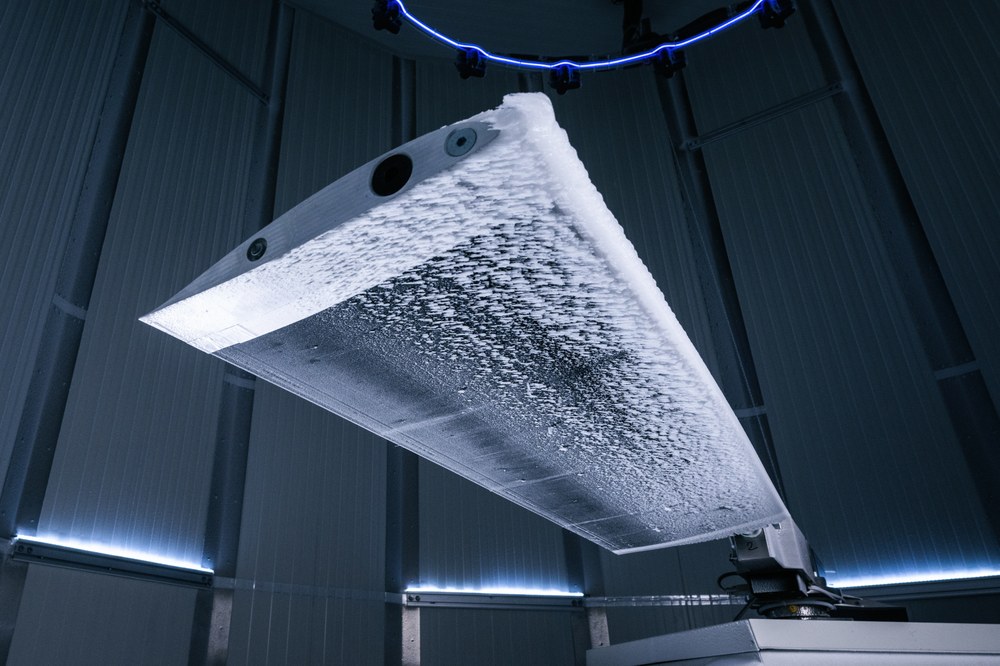

De-icing systems for rotor blades must meet stringent requirements in terms of weight, size, and power consumption, especially for small and medium-sized helicopters. The rotor tower at the DLR Institute of Flight Systems houses a test rig that allows the testing of rotors with a diameter of up to 4.2 metres. This facility has been expanded into a test stand specifically for the icing and de-icing of rotor blades.

To this end, a deep-freeze chamber was installed in the tower, enabling experimental investigation of de-icing technologies for rotor blades under realistic atmospheric icing conditions at temperatures as low as -25°C. A spray system mounted below the ceiling can disperse a water-air mixture, which leads to controlled icing conditions.

This test stand – unique in Europe – marks a departure from the conventional method of testing de-icing systems on non-rotating profiles in wind tunnels. It introduces centrifugal loads into the process, allowing the influence of centrifugal force on the energy requirements for de-icing to be taken into account. This enables the development of more efficient and energy-saving systems.