Technologies for flight simulation

Flight simulations make a significant contribution to the development and assessment of new aircraft systems. The Institute of Flight Systems uses specialised simulation methods to realistically model systems, test concepts, and reliably support technological innovations.

Real-time simulation of flight systems

Dynamic real-time simulation plays a central role in the maturation of new aircraft systems and components. These simulations allow innovative system designs to be validated in the early phases of development while revealing complex interactions between systems.

The Institute of Flight Systems is equipped with powerful computer platforms capable of conducting even the most demanding multidisciplinary system simulations. These simulations benefit from the ability to run in hard real-time across multiple cores, processors, and FPGAs (Field Programmable Gate Arrays) in parallel.

A wide range of virtual testing methods is covered, from model-in-the-loop (MIL) to software-in-the-loop (SIL) and hardware-in-the-loop (HIL). The focus is particularly on safety-critical onboard systems in areas such as flight control, actuation, avionics, and the simulation of data busses and their electrical or hydraulic power supply.

Thanks to standardised interfaces, seamless integration of models from adjacent domains, such as aircraft structures or aerodynamics, is made possible. This holistic approach significantly enhances the efficiency and safety of developing innovative aircraft systems.

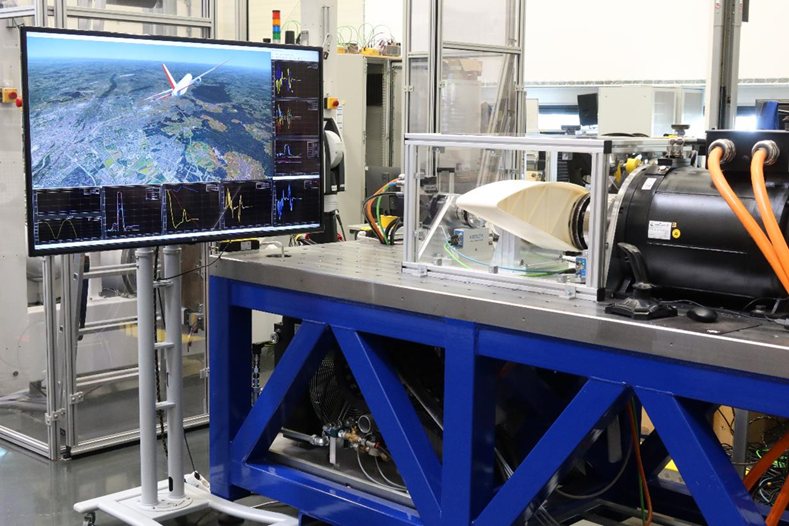

Hardware-in-the-loop simulation of actuators

The development and testing of novel actuator-centered control concepts such as torque-based flight control is supported by hardware-in-the-loop simulation. This involves the coupling of a real rudder actuator, for example installed on a test bench, with a flight dynamics simulation model that represents a so-called hardware-in-the-loop simulation. The interactively controllable, real-time capable flight dynamics model sends position or torque commands to the real rudder actuator. The aerodynamic load calculated by the flight dynamics model is applied to the rudder actuator with the aid of a loading device. The feedback of the current rudder position and rate to the flight dynamics model closes the loop so that the rudder actuator, including its control, is embedded as real hardware in a simulation of its environment represented by the flight dynamics model. This means that tests and evaluations of the influence of new flight control or actuator control concepts on the overall aircraft dynamics can already be carried out on the ground. In this way, flight tests can be prepared or the scope of required flight tests can be reduced.

Passenger comfort evaluation using DLR’s AVES motion simulator

At the Institute of Flight Systems, researchers investigate how novel aircraft technologies affect passenger comfort. For this purpose, the Air Vehicle Simulator (AVES) is used in combination with the Advanced Future Cabin (AFC) to simulate the dynamic behaviour of innovative aircraft configurations. The aim is to systematically analyse how these technologies influence passengers' perceived comfort.

Previous studies have investigated the impact of virtual windows and the use of virtual reality headsets during the flight on motion sickness. Virtual windows are display screens which replace the cabin windows. Virtual reality headsets could be used in combination with future in-flight entertainment systems.

Future aircraft designs present new challenges for passenger comfort. More flexible aircraft or novel concepts such as flying wing configurations give rise to unfamiliar motion spectrums and patterns—for example, combined roll, yaw and heave motions. These are simulated using the AFC to measure and gain deeper insight into how physiological responses are triggered and evolve over time.

The AFC and its associated research methods are continuously being developed further to increase the precision of the measurements and the validity of the drawn conclusions.

Flight testing of new configurations

To evaluate the performance and handling characteristics of novel aircraft configurations, the institute conducts unmanned flight tests controlled from a ground station. These tests allow the exploration of flight dynamic limits without endangering onboard personnel. Key objectives include extremely short take-off manoeuvres and steep approaches in confined areas. The research focuses on new approaches to distributed electric propulsion for propellers and rotors, as well as advanced flight control functionalities.

For this purpose, an electrically powered gyroplane prototype with a take-off mass of 400 kilograms has been specially outfitted. It is equipped with three electric motors delivering a combined output of 70 kilowatts and features a dedicated flight control system. A comprehensive data acquisition setup records all critical parameters, providing a robust basis for assessing flight performance, dynamic behaviour, and overall system safety.