Additive manufacturing for durable and reliable ship components

- For the maritime industry, Wire and Arc Additive Manufacturing process allows to produce customized components such as propellers, doorframes or stiffeners quickly and cost-effectively.

- Funded by the Federal Minstry for Economic Affairs and Energy, LAYER is investigating how additively manufactured ship components can become more robust using the WAAM process.

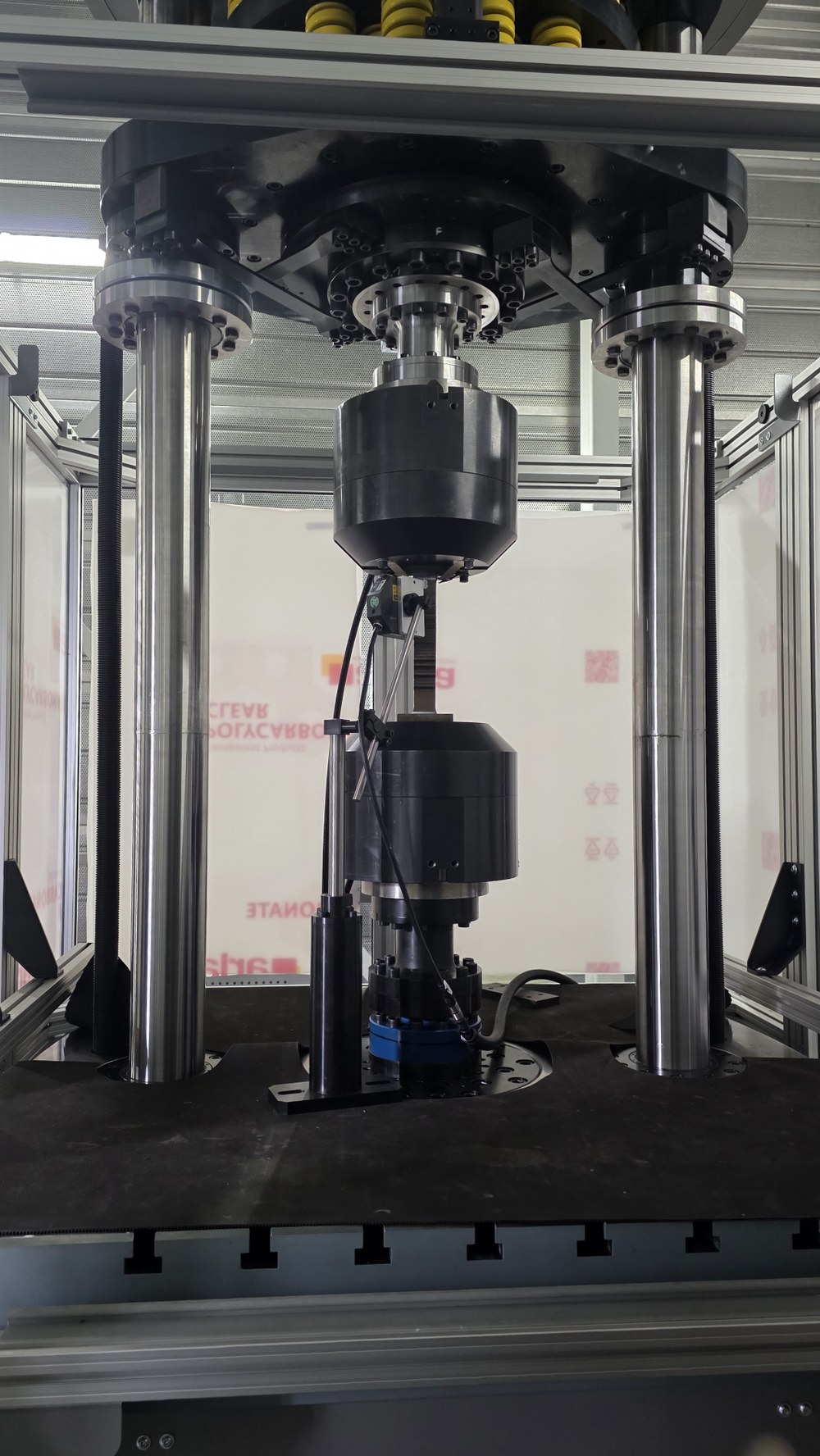

- The 150kn Resonance Machine is located in Clausthal.

How can ships remain safe and reliable even after decades at sea? This question is at the heart of our project LAYER. We are investigating how the service life of additively manufactured metallic components can be extended and how their fatigue strength can be predicted more quickly and more accurately.

At the core of our research is the Wire and Arc Additive Manufacturing (WAAM) process. In this method, metal wire is melted by an electric arc and deposited layer by layer. This makes it possible to manufacture large and complex components efficiently or to repair existing parts in a targeted way. For the maritime industry, WAAM opens up the opportunity to sustainably refurbish highly loaded components instead of replacing them.

Our research goals and first results

We are exploring how surface treatments and hybrid manufacturing strategies can improve the fatigue life of WAAM components. A key focus of our research is on accelerating fatigue-life prediction using thermo-structural numerical simulations that we validate through experiments. First results are promising. On our 150 kN resonance testing machine, we have already generated SN curves for WAAM-reinforced ship doorframes.

Our long-term goal is to establish WAAM in combination with hybrid treatments as a standard manufacturing route in shipbuilding and offshore applications. We aim to reduce costs, extend component lifetimes, increase sustainability and enable new ship designs.

Our project partners

Mecklenburger Metallguss GmbH (MMG), Meyer Werft GmbH & Co. KG, Laser Cladding Germany GmbH, Ing. Grimm Schweißtechnik GmbH, HiFIT Vertriebs GmbH, Karstens Watercut & Welding, TRIMET Aluminium SE, HAW Hamburg

BMWE

Kontakt

Dr. Moritz Braun