SysDamp

Innovative methods to determine damping for realistic service life predictions of new wind turbines

SysDamp

In SysDamp, different experimental and numerical methods will be pursued with the aim of developing a strategy for future prototypes of wind turbines to determine damping parameters from field measurements that can be transferred to the design process of new turbines.

Motivation and background

Current wind turbine rotors have increased flexibility due to longer and slender rotor blades, which leads to higher bending and an increased tendency to vibrate at high wind speeds. These vibrations induce dynamic loads that influence the service life of the turbine, which is why precise knowledge of the damping and system responses is crucial for the design and service life analysis of the wind turbines in order to limit the amplitudes of the vibrations and accelerate their decay.

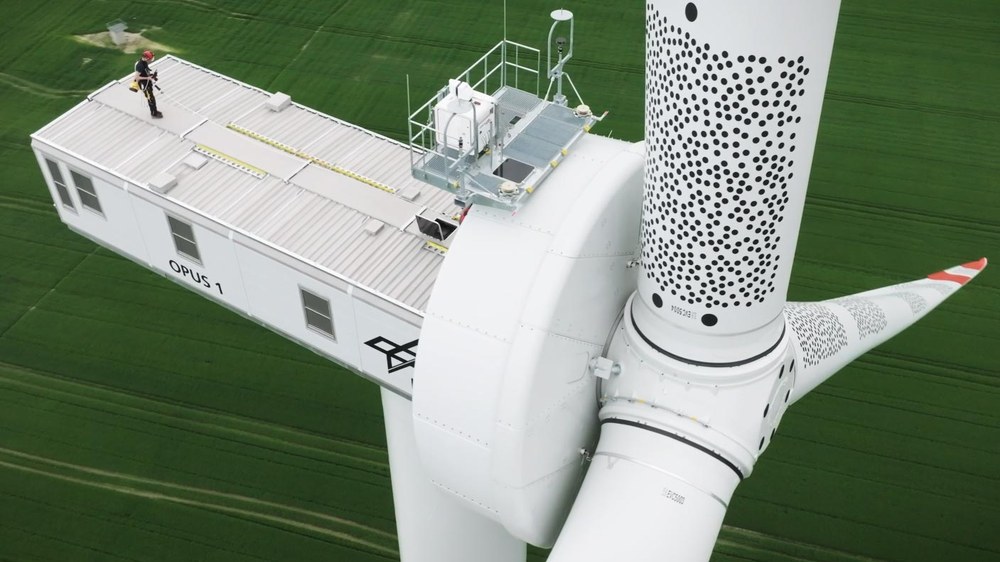

The WiValdi research wind farm in Krummendeich, with its comprehensive instrumentation of acceleration and strain sensors for wind turbines, offers an excellent basis for determining damping from experimental data without having to integrate additional complex sensor technology into an existing turbine.

Challenges

In SysDamp, different methods are investigated with the aim of developing a strategy for future prototypes, determining damping parameters from field measurements and transferring them to new systems to be developed. There are currently no guidelines for this. The attenuation of the overall system is to be identified and evaluated using innovative artificial excitation as well as classic ambient excitation from wind and microseismics with different identification algorithms and by different users. By comparing the numerical models, the damping models for the design of new wind turbines can be raised to a new level. This enables more precise load analyses.

Objectives

-

Generation of measurement data with sensors already installed on a wind turbine in the WiValdi research wind farm to determine the modal damping of the entire turbine.

- Generation of measurement data with already installed sensors on a wind turbine in operation under specifically controlled operating modes, some of which are also in the off-design.

- Development of methods to determine the damping values of the tower and blade modes of the entire wind turbine from measurement data using accelerated, fully automated approximation algorithms in the time and frequency domain with the aim of being able to track more than 15 modes.

- The model and result validation of the aeroelastic simulation of the wind turbine is carried out with the damping parameters identified from the field test, whereby component (section) loads in various load cases are compared with the test data and a comparison is made with conventional models.

- Automated comparison of the damping of measurement and simulation with an increase in model quality and prediction accuracy.

- Determination of the influence of fuzzy damping parameters by means of sensitivity analysis.

Project | SysDamp - Innovative methods for determining damping for realistic service life predictions of new wind turbines |

|---|

Duration | 01/2024 - 12/2026 |

Partners | - Wobben Research and Development GmbH (WRD)

- SPEKTRA Schwingungstechnik und Akustik GmbH

- Leibniz Universität Hannover (LUH)

- DLR Institute of Aeroelasticity (Project management)

- DLR Wind Energy Experiments

- DLR Institute of Flight Systems

|

Type of project | Research project |

Funding organisations | Federal Ministry for Economic Affairs and Climate Action (BMWK) over Projektträger Jülich (PTJ) |