Predictive Maintenance

Predictive maintenance is a method for minimizing downtime, reducing maintenance costs, and enhancing vehicle safety and reliability.

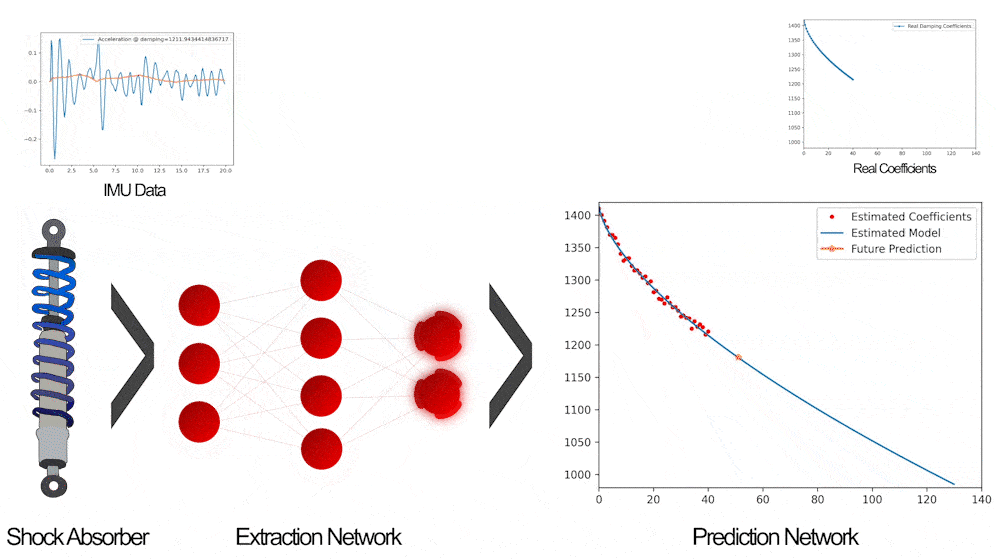

Predictive maintenance of shock absorbers

A shock absorber is predestined for predictive maintenance, as it is vital not only for a comfortable driving experience but also for ensuring vehicle safety. This becomes even more critical in automated driving, where vehicles need to self-monitor and schedule maintenance before any component failure occurs.

We have developed a machine learning-based methodology to predict the degradation of shock absorbers and provide predictive maintenance recommendations. By leveraging intelligent techniques to analyze vehicle dynamics, we can extract system health information and forecast its future state. To achieve this, we utilize operational design domains* to define the threshold until vehicle functionality remains unrestricted and safety is uncompromised.

*The Operational Design Domain describes the specific operational environment in which an automated vehicle or driving function can be safely operated.

The use of AI-based predictive maintenance will benefit the automotive industry by reducing unexpected breakdowns and extending component lifespan, particularly in automated vehicles. Vehicle manufacturers can enhance vehicle reliability and safety, reducing repair costs and improving customer trust. This proactive approach strengthens trust in the safety and reliability of automated driving systems.