Coating laboratory

The DLR Coating laboratory in Oldenburg is a research facility of the Institute of Solar Research. Here, researcher work closely together to develop innovative materials and coatings for various energy applications.

This research facility involves applications in the fields of energy conversion, novel photovoltaics (PV), radiative cooling, hydrogen technologies and concentrating solar power. Coating technologies are resource-efficient, flexible, cost-effective and lightweight, which makes them attractive for many applications.

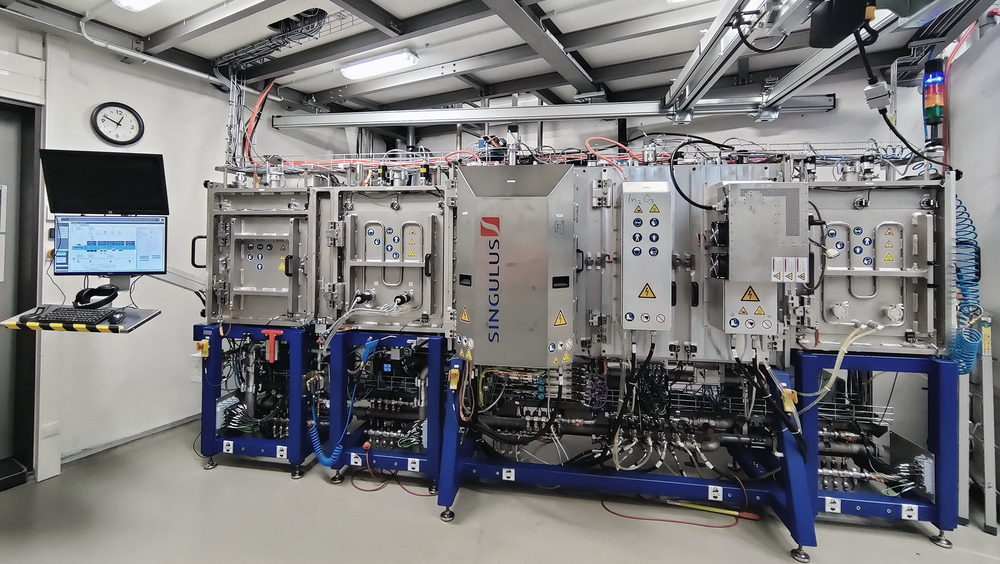

The laboratory plays a decisive role in the development and analysis of coatings and functional surfaces. It offers a variety of coating tools, front-end and back-end systems as well as various characterisation methods to produce thin-film technologies. These can be seamlessly integrated into prototype devices such as PV windows, photoelectrochemical cells, fuel cells and mirrors for solar thermal power plant heliostats. The laboratory is geared towards the reliable and reproducible production of prototypes with a high degree of technological maturity and meets industrial standards. It has state-of-the-art coating machines that can implement manufacturing processes that industrial partners use for mass production.

Research infrastructure in detail

The combination of inline systems supports substrate sizes of up to 30 x 30 square centimetres. These are tailored to the development of processes and prototypes on an almost industrial scale.

The most important components include:

- An industrial glass cleaning system

- A magnetron sputtering system for the deposition of transparent conductive oxides (TCO), metals, metal nitrides, oxides and oxynitrides using pulsed DC, RF, HiPIMS and bipolar MF processes on planar and rotatable targets

- A lamination unit and an ultrasonic soldering station for bonding and contacting coated substrates for prototyping

In addition to the R&D (research and development) production line, the institute has a well-equipped characterisation laboratory that supports numerous methods. These include a combined system of scanning electron microscopy (SEM) and focussed ion beam (FIB), an ellipsometer, a Hall sensor, various spectrometers (UV/VIS/NIR, Raman, FTIR) and a wide range of electrical and optical measurement methods for the thin-film technology demonstrators produced.