Department Aeroelastic Experiments

The department Aeroelastic Experiments is committed to the planning, realization and analysis of challenging experiments in wind tunnels.

In our previous technical post from the “Article series Non-Rotating Annular Cascade Test Facility”, we explained why aeroelastic investigations in wind tunnels are crucial for understanding and preventing flutter – and how the Non-Rotating Annular Test Facility plays a central role in analyzing the aeroelastic behavior of turbomachinery blades. In this article, we focus on the practical side: How are pressures and blade movements measured? And how can we derive aerodynamic damping and flutter risks from them?

Modern CFD simulations provide detailed insights. However, especially in the transonic regime, they face physical and modeling limitations. Nonlinear interactions between shock waves and blade vibrations can occur here – and these are extremely challenging to capture computationally. Carefully designed experiments provide essential reference data – both to validate simulations and to deepen our understanding of aeroelastic phenomena.

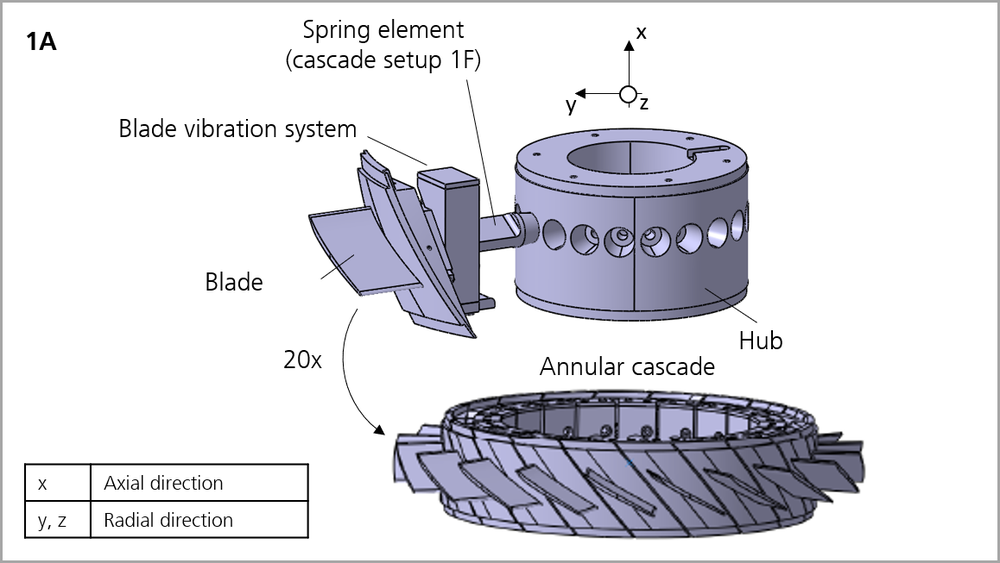

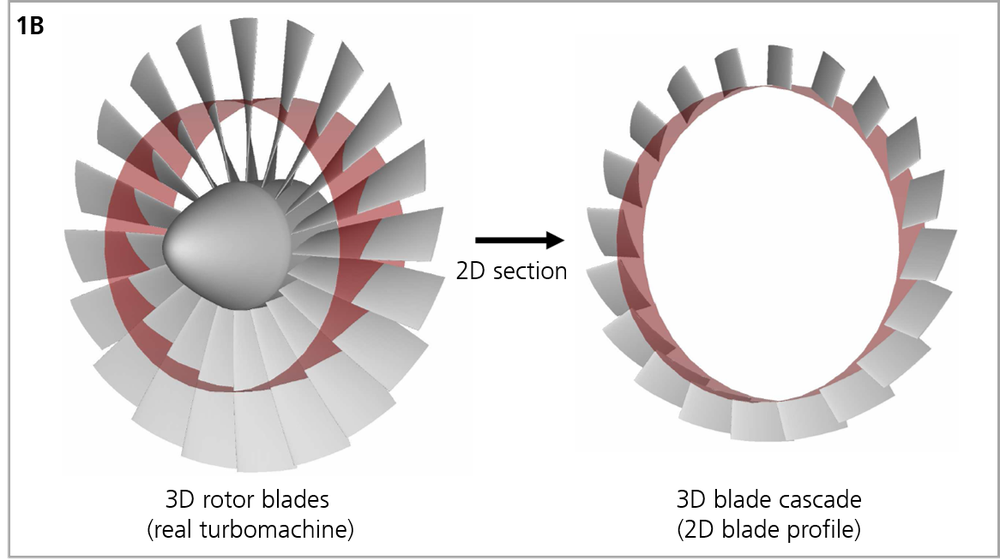

At the core of our measurement campaigns is a ring-shaped blade cascade with 20 individually excitable blade vibration systems (Fig. 1A). This test model or “annular cascade” represents a 2D blade cross-section of a rotor blade, extruded to a length of 40 mm (Fig. 1B) – essentially a representative slice of a real 3D rotor blade.

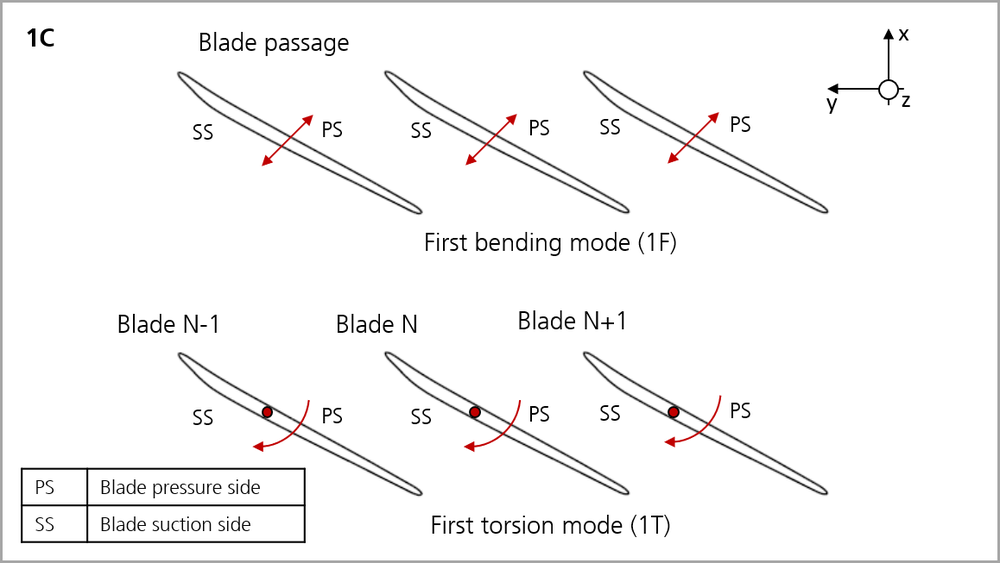

Each blade can be set to vibrate in two distinct structural modes (Fig. 1C):

These modes are achieved using custom-designed spring elements (Fig. 1B). For each mode – 1F (bending) and 1T (torsion) – a dedicated annular cascade setup is assembled. This approach ensures consistent and comparable datasets under identical flow conditions.

First, the blades are locked using a hydraulic brake. In this fixed state, we can set and measure steady-state flow conditions.

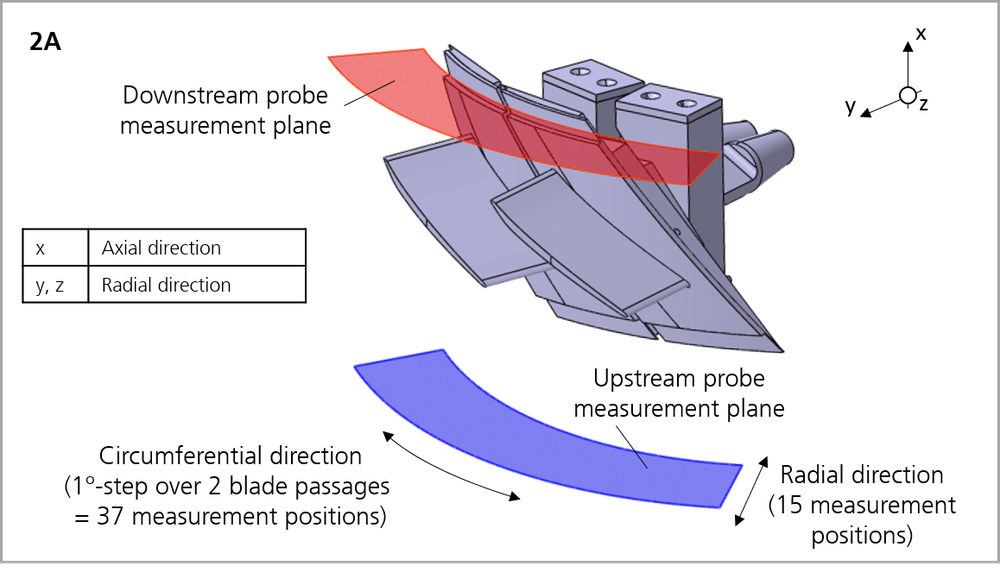

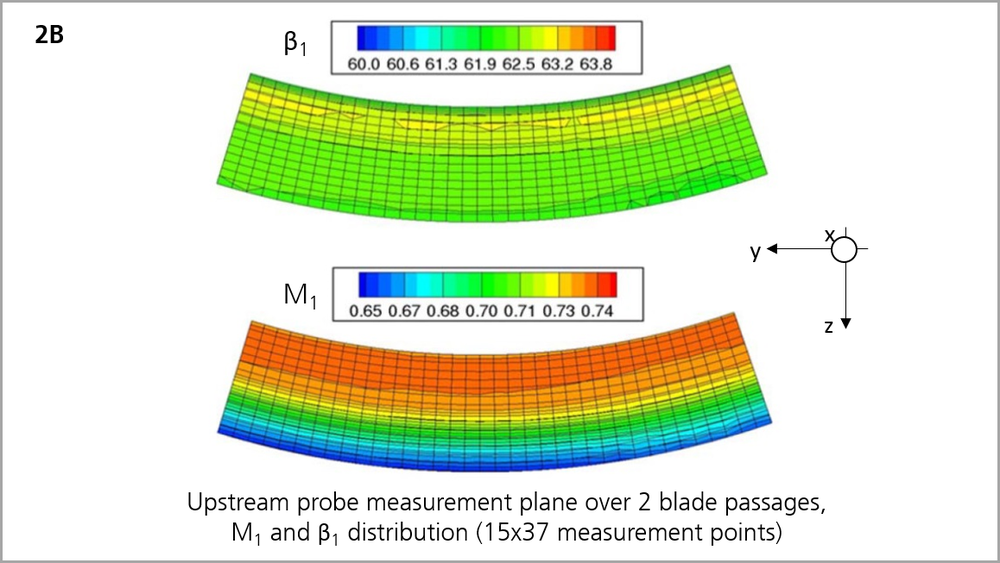

Two aerodynamic probes scan the flow field upstream and downstream of the annular cascade. By pivoting the cascade and adjusting the probes radially, we gather data at 15 radial positions and in 1° steps across two blade passages (Fig. 2A). This creates a high-resolution map of Mach number and inflow angle in one axial plane (Fig. 2B). Measuring across two adjacent passages allows us to assess flow periodicity and better identify local disturbances.

Next, we excite the cascade into vibration: The hydraulic brake is released, and displacement sensors begin tracking amplitude and phase of each blade’s motion in real-time.

Each blade is excited at its natural frequency – depending on the cascade setup, either in 1F or 1T mode. A central reference oscillator provides the excitation signal, distributed evenly across 20 blades. By adjusting and regulating the interblade phase angle (IBPA) and ensuring uniform amplitude, a traveling wave pattern emerges – like a "wave" in a stadium (Fig. 2C). This simulates realistic vibrations found in actual turbomachinery.

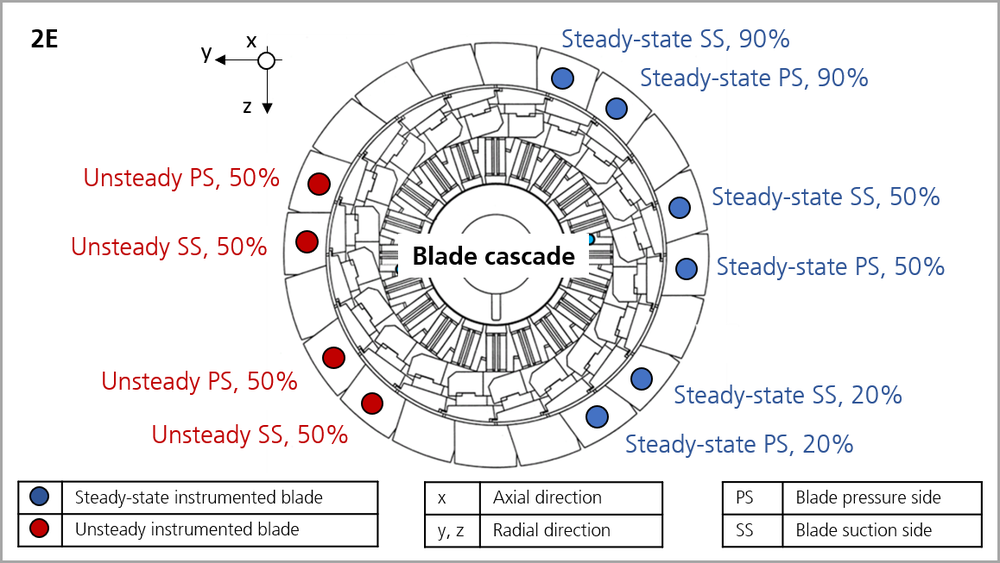

Aerodynamic forces on the blade surfaces are captured using:

Due to limited space inside the blades, pressure and suction sides are measured on separate, adjacent blades. This way, we reconstruct a full 2D pressure distribution around the blade profile – typically from 20 measurement points per blade.

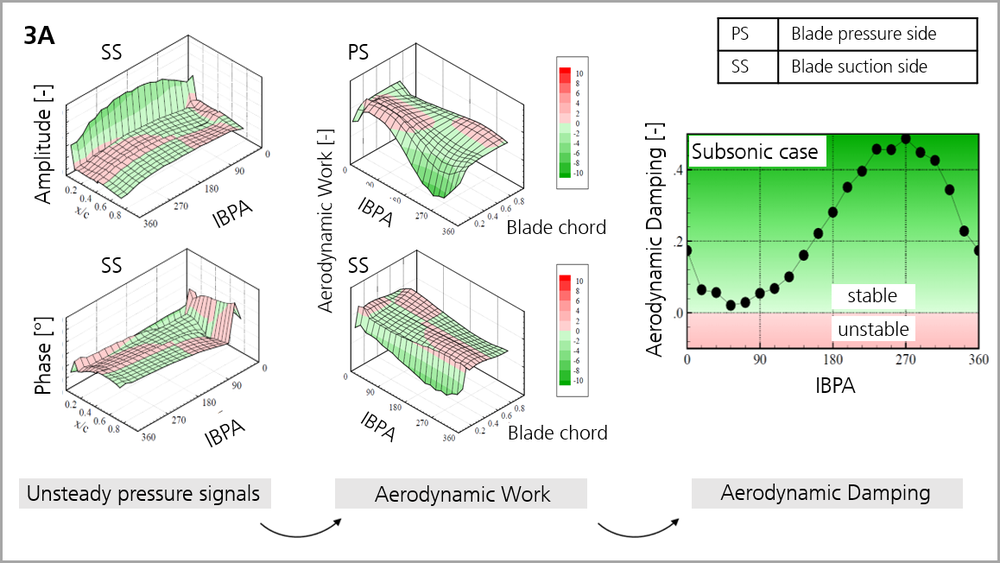

The central question of any aeroelastic investigation: Does the blade absorb energy from the flow – or release energy into it?

To answer this, we analyze (Fig. 3A):

This analysis is repeated for every IBPA, each flow condition in the measurement matrix, and both vibration modes (1F and 1T). A full measurement campaign typically takes about three weeks.

The combination of:

makes the Non-Rotating Annular Test Facility (RPG) a vital tool for validating CFD methods, understanding aeroelastic effects – and ultimately, designing more robust compressor and turbine blades.

In the upcoming articles of this series, we’ll show how operating conditions are precisely controlled, present typical results from steady and unsteady measurements, and explain how this data support the design of blades that are more robust against flutter. Stay tuned!

Virginie Chenaux, Department Aeroelastic Experiments, DLR-Institute of Aeroelasticity