Aeroelastic Experiments

The department “Aeroelastic Experiments” is committed to the planning, realization and analysis of challenging experiments in wind tunnels.

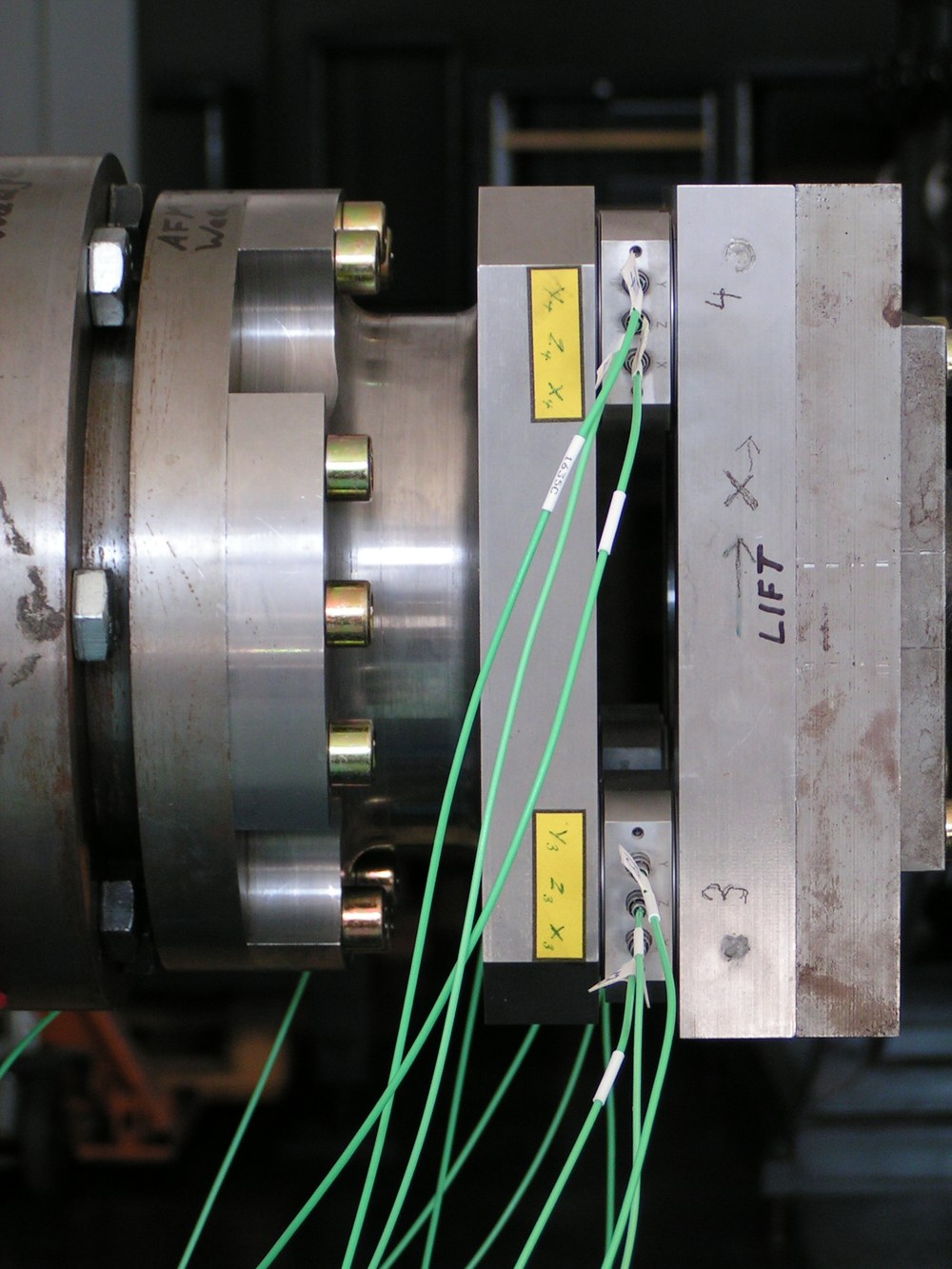

The piezoelectric sensors operate according to the piezoelectric effect: electric polarisation occurs upon mechanical deformation of crystals with polar axes. Depending on the cross section, in quartz, the piezoelectric effect manifests itself as a longitudinal, transversal or shear effect. Hence, it is possible to build force measurement elements made of properly cut slices of quartz that can be used to measure one or several components or moments, depending on the requirements. In most cases, the force measurement element will take the form of a washer containing several quartz discs under a light pre-stress in a mechanical series. Electrodes located between the quartz discs record the charges and transmit them to charge amplifiers and integrators.

Due to the systemic advantages of piezoelectric measurement technology, these kinds of sensors deliver a large dynamic response range, low crosstalk and high stiffness. Effective zero correction ensures that zero point drift errors are low, hence permitting quasi-static measurements over longer periods. Current sensors allow six-component measurements of the static and dynamic external forces. The full resolution capability is available independent of preload for the measurement of small fluctuations by means of short-circuiting the loads created by a stationary preload, therefore enabling force measurement across several magnitudes at constant resolution.

High stiffness leads firstly to low crosstalk between the individual force components, and secondly to a high natural frequency of the system as a whole. Both of these properties are of vital importance in the measurement of aerodynamic loads during wind tunnel experiments and are equally crucial during aeroelastic experiments.