ProCo - Propulsion and Coupling

Goals

ProCo pursues a holistic, integrated approach to the drive and chassis technology of rail vehicles. In order to enable climate-friendly, resource-efficient, economical and user-orientated rail transport, the following four cornerstones have been established:

- Energy - development of modular, scalable hybrid drive systems (hydrogen + battery) as a replacement for diesel.

- Efficiency - lightweight construction, low-loss traction, virtual coupling, digital twins.

- Economy - reduction of life cycle costs (LCC) through automation, energy optimisation and wear reduction.

- Ecology - CO₂ reduction, moving away from diesel, environmentally friendly operating strategies

Energy

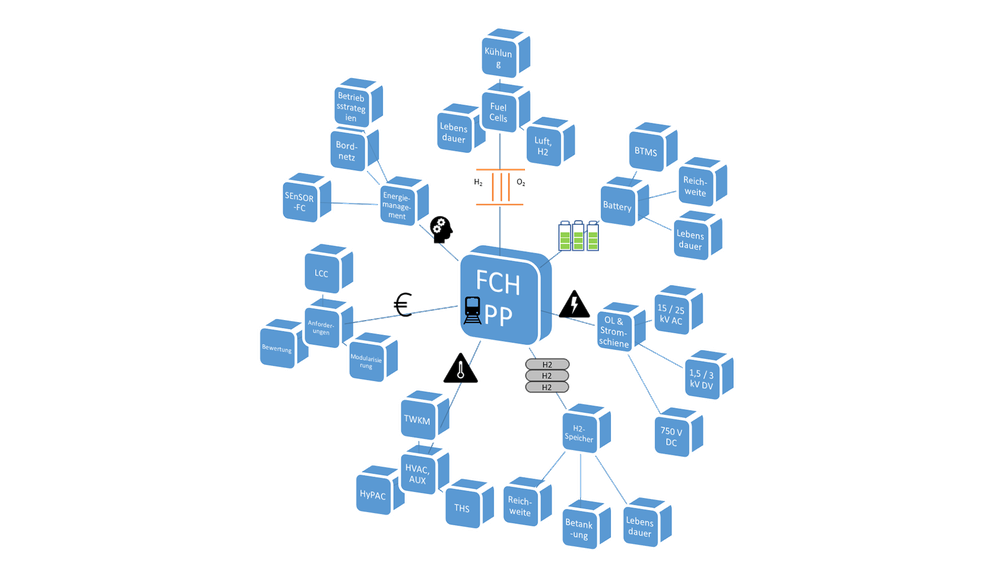

The replacement of diesel trains for environmental reasons and the recommissioning of closed lines have raised the question of which hybrid drive concept is best suited to each individual non-electrified railway line. Battery and/or hydrogen trains enable the transition to environmentally friendly energy sources. Energy storage is the key to train concepts with hybrid drives. New intelligent solutions for hybrid energy supply concepts need to be investigated in order to optimise overall performance from cradle to grave. The aim is to develop and demonstrate a scalable, modular system kit for hybrid drive systems with standardised interfaces.

Efficiency

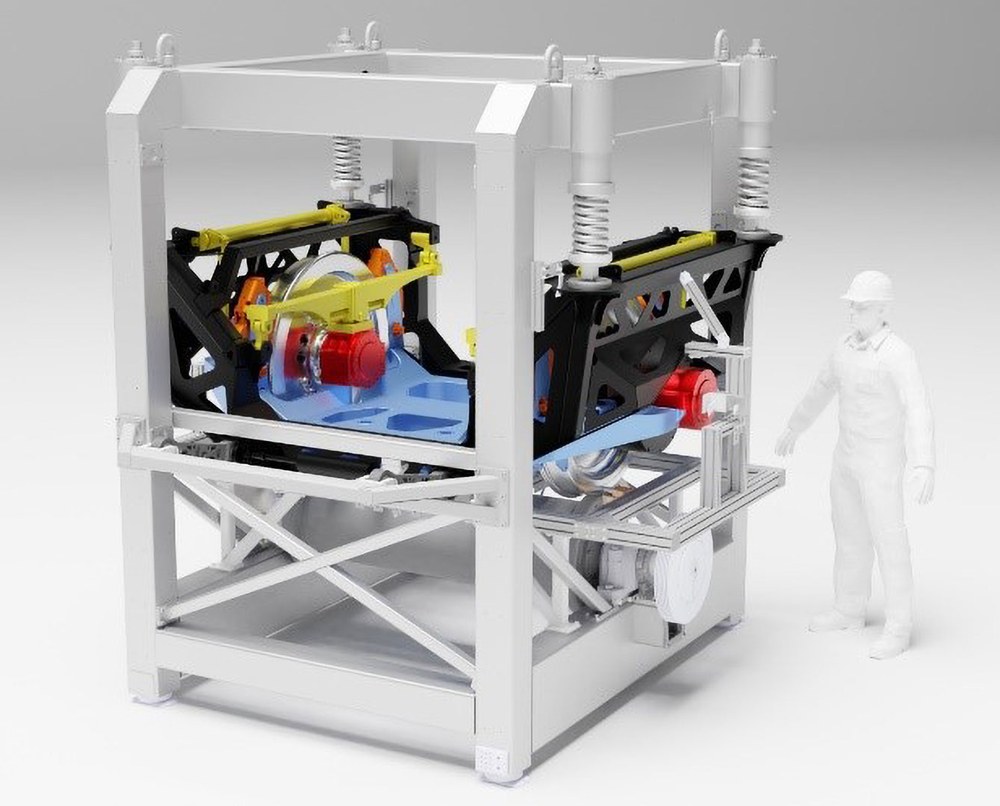

Advanced technologies such as low-loss traction must be investigated and applied to the requirements of railway applications, with the NGT family of trains serving as lead concepts and demonstrators. Accompanied by an extensive investment project, the full-size single-wheel bogie is being built and tested both on a rolling test rig and on track systems in order to advance and demonstrate the technological maturity of the implemented technologies.

Economy

It is essential for railway operators to realise economical operation. Potential for reducing life cycle costs in the rail system lies in the optimisation and automation of operational processes, e.g. through virtual coupling, in the reduction of energy requirements and in the reduction of wear and associated maintenance costs. The systematic and targeted organisation of their technical design and the corresponding technologies is necessary for the economical use of future rail vehicle drives that are tailored to requirements. To make this possible, the intelligent use of methods and tools to determine the LCC and its development is indispensable.

Ecology

Reducing emissions and the carbon footprint in the mobility sector, particularly in rail transport, is a challenging task and plays an important role in increasing the acceptance of new technologies in society. The integrated consideration of energy supply and drive components and driving modes / manoeuvres will consistently reduce the environmental impact. Furthermore, the replacement of diesel traction is being driven forward, which is an important lever for reducing the CO2 footprint. The aim is to develop and optimise operating strategies and suitable tools to reduce energy requirements and emissions.

Technological focus

NGT-Bogie

Mechatronic lightweight single-wheel running gear with direct drive close to the wheel (TRL 6). Advantages: less wear, quieter, more energy-efficient, better track guidance. Tested on the NGT-FuN test bench and later under real-life conditions.

High-tech bogie for the train of the future

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

Virtual coupling (VCTS) Enables the dynamic winging (joining/separating) of trains during the journey. Goal: higher route utilisation, more flexible train compositions, automation. Use of precise self-localisation (e.g. magnetic field sensors).

Video : Future technologies for rail transport - measurement campaign in the laboratory train, March 2021 (engl.)

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

DLR

Fuel Cell and Hybrid Power Pack (FCHPP)

Modular construction kit for scalable hydrogen/battery hybrid drives. Objective: requirement-orientated energy supply for non-electrified routes. Focus on interface standardisation, energy and cost efficiency.

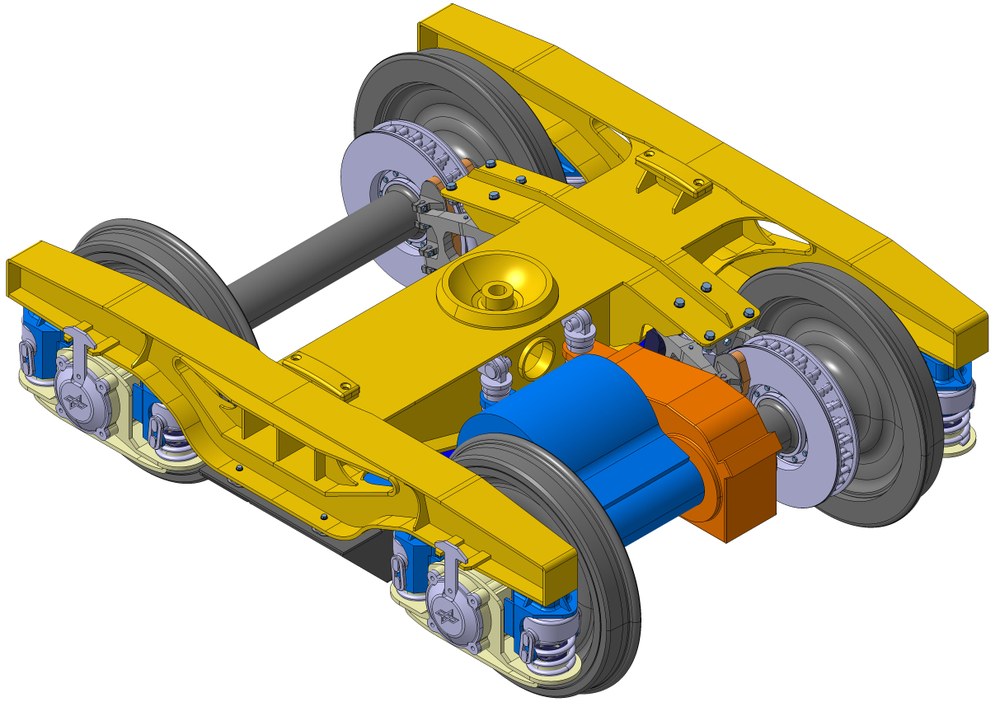

Self-propelled goods wagon bogie (ASINO-DG)

Drive and energy system integrated directly into the freight wagon bogie. Application: Self-sufficient operation on the "last mile", without shunting locomotives. Advantages: More flexible logistics, reduced operating costs, plug-and-play solution

Methodology

- Digital twins as a central development and optimisation tool

- Modelling of vehicle, infrastructure and operation.

- Sensitivity analyses, multi-objective optimisation between energy, efficiency, economy, ecology,

- Combination of simulation, test bench trials and demonstrators,

- Synergies with other DLR and EU projects (e.g. FCH2RAIL, Shift2Rail).

Overall objective

Technological innovations in propulsion, running gear, energy supply and digital networking are intended to make rail transport in the passenger and freight sector

- more attractive for users and operators,

- more cost-efficient,

- more energy and resource efficient,

- and more climate-friendly.

Beyond the boundaries of the ProCo project, there is close cooperation with other projects in the programme themes of rail transport (InTra, TraCo and RoSto), transport systems (Vmo4Orte) and road transport (FFAE). At European level, the ProCo project is closely linked to the Europe's Next Rail Joint Undertaking and the FCH2RAIL project funded by the Clean Hydrogen Partnership.

Runtime

2022 - 2025

Total budget approx.

14 Mio. €

Participating institutes

- Institut für Fahrzeugkonzepte

- Institut für Aerodynamik und Strömungstechnik

- Institut für Bauweisen und Strukturtechnologie

- Institut für Faserverbundleichtbau und Adaptronik

- Institut für Instandhaltung und Modifikation

- Institut für Softwaretechnologie

- Institut Systems Engineering für zukünftige Mobilität

- Systemhaus Technik

- Institut für Systemdynamik und Regelungstechnik