ATHEAt

Within ATHEAt, the DLR Institute of Software Technology is responsible for analysing selected ground test and rocket flight data using algorithms from the field of artificial intelligence. The analysis is divided into several detailed tasks, ranging from the evaluation of optical measurements to the detection of anomalies in flight data.

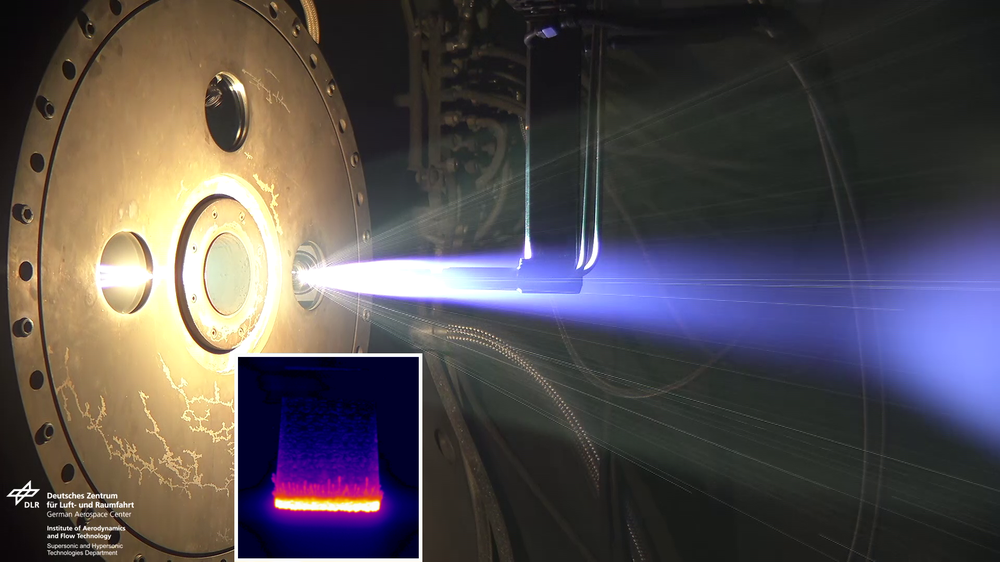

During the project, various wind-tunnel experiments are performed in preparation for the planned sounding rocket launches. Image 1 shows in the upper half one such experiment with a small section of the leading edge of a rocket fin in the L2K wind tunnel. During this experiment, a hot gas stream is injected from the right onto the leading edge, creating conditions comparable to those during atmospheric re-entry. In this specific case, the fin was manufactured from a composite material, which deforms under these extreme conditions, while melted material accumulates at the sides of the structure.

DLR-Institut für Aerodynamik und Strömungstechnik, DLR-Institut für Softwaretechnologie

The Institute of Software Technology develops algorithms to analyse the deformation and melting of materials observed in the experiments. Our goal is to quantify changes in the leading-edge shape as well as the extent and distribution of melted material. As a first step, we segment the images to identify the different parts of the fin, enabling detailed quantitative analysis. The lower image shows such a segmentation, where each pixel is classified into distinct regions of the fin and the background. We use neural networks based on a U-Net architecture automatically create these segmentations. Furthermore, the uncertainties of these detection results are estimated using statistical methods of uncertainty quantification.

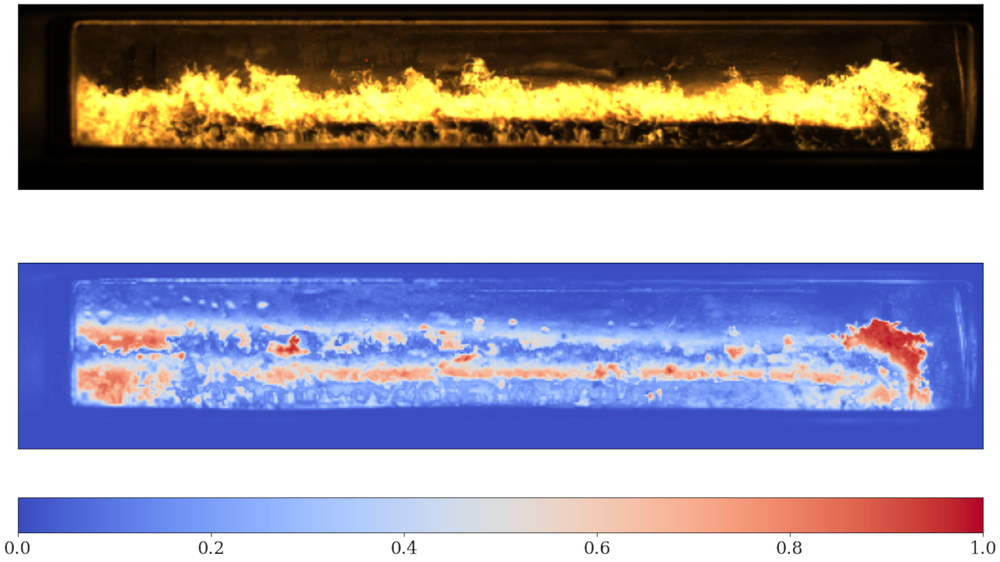

In addition to these wind-tunnel experiments, the Institute also analyses combustion experiments with hybrid rocket fuels. The upper half of image 2 shows a frame from a high-speed video capturing such a combustion test. In these experiments, a solid fuel block is placed inside a special combustion chamber with optical access, while a fluid oxidizer is injected from the right. After ignition, the combustion process is recorded with several sensors, including a high-speed camera.

DLR-Institut für Aerodynamik und Strömungstechnik, DLR-Institut für Softwaretechnologie

The Institute of Software Technology develops algorithms to detect combustion instabilities in such video data using both density-based algorithms as well as customised neural networks based on autoencoders and vision transformers. The lower image shows the result of one algorithm, highlighting regions where pixel behaviour deviates from expectation. At a recording rate of 10,000 frames per second, detecting even small local deviations requires substantial computational effort.

Project runtime:

- 2021-2026

Scientific participants: