Virtual Tester

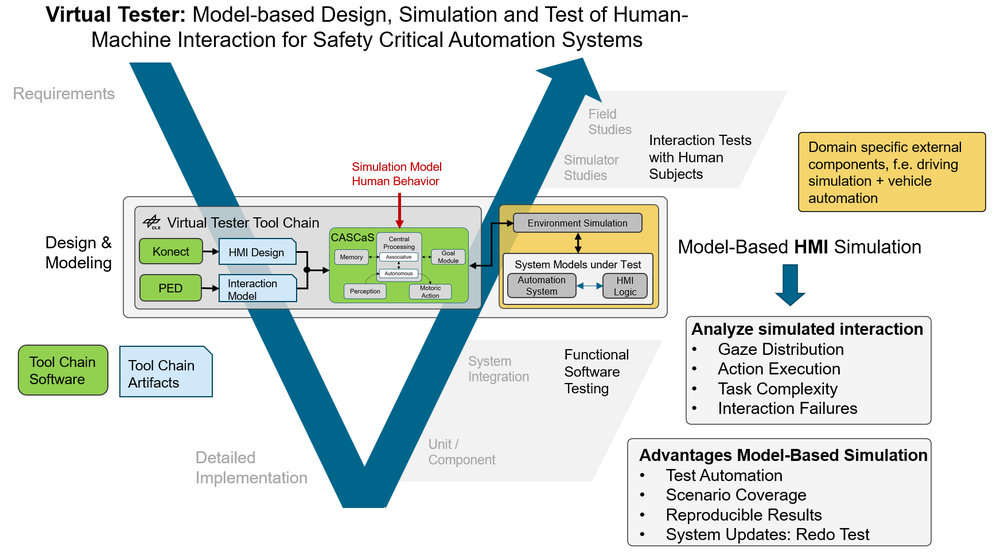

The Virtual Tester is a model-based tool chain which allows to evaluate various Human-Machine Interface (HMI) concepts in the early development stages of an automation system.

Model-Based HMI Simulation for Efficient Development of Automated Systems

In the context of a development process, the tool chain fits between pure functional software testing of the automation system and late field study testing involving human participants and real physical systems. To investigate f.e. suitable handover times, different measures can be assessed based on the simulation results, e.g. gaze distribution, action execution times or task complexity.

Consisting of three different software tools, HMI designers, automation system developers and test engineers can systematically design, model, simulate and analyze the interaction between the automation system, the HMI and the human user. Starting with an HMI design prototype using Konect and a formal specification of the interaction task in PED, the human interaction behavior can be simulated by the cognitive architecture CASCaS. Connecting CASCaS to a domain specific simulation environment (e.g. automotive, aerospace, maritime) allows the integration into existing simulation and test environments used by OEMs and suppliers of automation systems.

The advantages of a model-based tool chain include test automation, large scenario coverage This allows for more efficient testing with the objective of reducing the time-to-market of such systems and their updates, while in parallel increasing their quality.

Read More

SafetyLoop Lab – Motion Simulator

More about the SafetyLoop Lab, a high-dynamic test platform featuring a hexapod motion simulator, test vehicle, and state-of-the-art human–machine interaction environment:To SafetyLoop Lab – Motion Simulator