High temperature laboratory HITS

In solar thermal power plants, the concentrated solar radiation generates very high temperatures. The components used here must therefore be particularly heat-resistant. Whether they are suitable for use at extreme temperatures can be tested in advance in the laboratory. The Stuttgart High Temperature Laboratory (HITS) at the Institute of Solar Research has a suitable infrastructure for this.

This infrastructure enables tests with different heat transfer materials at over 1,000 degrees Celsius. Various test stand components, a measurement data acquisition system and measurement and control hardware that can be flexibly adapted to the needs of the user are available for test operation.

The following test infrastructure is available:

Hot air supply

Hot air flows through the components to be tested in a test section. With the help of a side channel compressor, volume flows of up to 80 cubic meters per hour are possible here. The maximum achievable overpressure is 500 millibar. The downstream electric air heater with an output of up to 40 kilowatt can heat the air flow up to 1,200 degrees Celsius.

Infrared heater

The Stuttgart high-temperature laboratory has six infrared emitters, each measuring 150 x 230 millimeters, which can be arranged as required. The emitters can each be operated with up to 10 kilowatt power and achieve radiation flux densities of up to 300 kilowatts per square meters. The wavelength at the radiation maximum is 1.2 micrometer. The infrared heaters can be combined with the hot air test section.

The system can provide a total heating output of up to 100 kilowatt.

CentRec300® test setup

To advance and validate innovative materials and design concepts for centrifugal solar thermal particle receivers, a dedicated test rig has been established at the DLR laboratory in Stuttgart. This test facility enables comprehensive evaluation of various particle types, feeding mechanisms, collector structures, transport systems, and inliner components. The surface on which particles move from the inlet to the receiver and are heated by solar radiation is referred to as the inliner.

Designed with modularity in mind, the test rig allows for the interchangeable replacement of all components within the rotating cavity, facilitating flexible testing protocols for emerging concepts. Furthermore, the receiver’s angle of inclination can be precisely adjusted to simulate a range of realistic operating conditions.

This test rig constitutes a critical intermediate step towards the upscaling of the receiver technology, paving the way for subsequent validation in the large-scale testing facility located in Jülich.

The key dimensions of the CentRec300® system are as follows:

- Aperture diameter: variable

- Diameter of the receiver inliner: 0.8 meter

- Length of the receiver inliner: 1.2 meter

- Design thermal power: 300 kilowatt thermal (used in Stuttgart only for cold testing)

- Particle mass flow rate: up to 1 kilogram per second

- Design rotational speed: up to 70 revolutions per minute

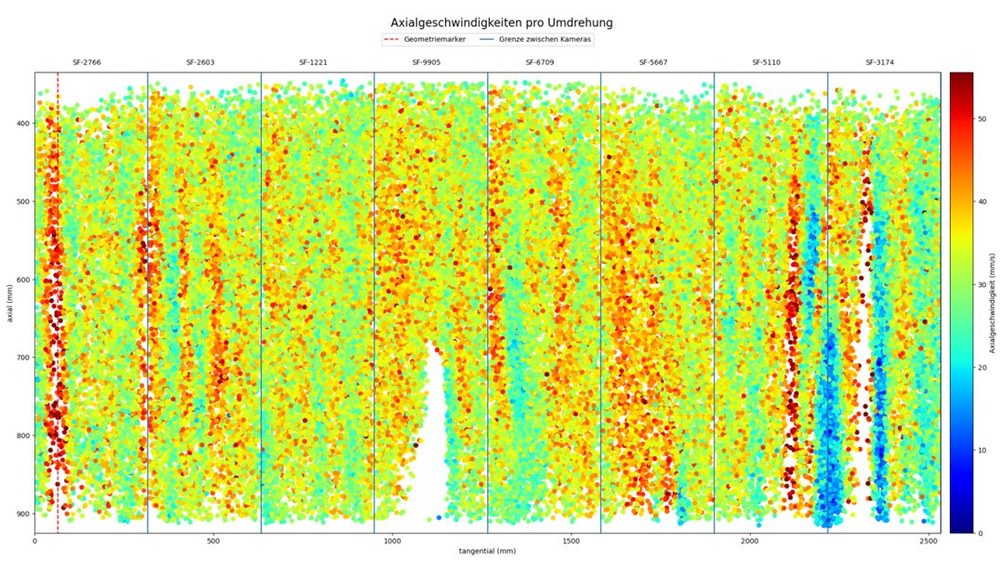

Particle measuring devices and the qualification of inliner concepts

To determine the quality of the particle film flowing in the centrifugal receiver, the DLR particle team has developed, built and patented measuring devices to measure the particle film velocity and particle thickness.

During operation of the centrifugal receiver (CentRec®), it is essential to maintain a homogeneous particle film on the inliner surface in order to avoid the formation of so-called hot spots, which would lead to material deformation, inhomogeneous film quality and consequently to lower efficiencies and output temperatures.

Trickle-Flow Heat-Exchanger (TFHX)

Ceramic particles represent a viable alternative as heat transfer and storage medium in concentrating solar tower systems. The particles are heated in solar-receivers close to 1,000 degrees Celsius. To transfer the stored heat in the particles the principles of a trickle flow reactor, was considered to be superior compared to state-of-the-art technologies, like fluidised bed- or cyclone-HX. The trickle-flow heat exchanger (TFHX), i.e. a particle-gas heat exchanger, provides a relative high power density at a relative low pressure drop, meeting the requirement for the use in a CSP tower system.

In the Stuttgart test Lab, for the highest air inlet temperature, the power density of the investigated TFHX was determined over 1,000 kilowatts per cubic meter. The volumetric heat transfer coefficient ranges in the same flow conditions at approximately 15 kilowatts per cubic meter, with a Number of Transfer Units (NTU) for the particle and air flow of approximately five and eight respectively.

It was shown and discussed, that the developed TFHX in this work is capable to increase the determined power densities, volumetric heat transfer coefficients, and NTU values by approximately 100 percent compared to the available data in literature. It is assumed, that the increase in performance can be deduced by an increased surface of the trickling particles within the packed column, or conversely by a reduced sink velocity of the grains of approximately 0.1 meter per second, compared to the determined velocities of roughly 0.2 meter per second in the literature. This leads to the assumption that an optimised packing structure in a trickle flow reactor is capable to increase the surface that interacts with the gas flow and therefore can enhance the heat transfer capabilities substantially.