The Institute of Solar Research develops appropriate testing methods to ensure the reliable operation of the systems. They minimise the risk of material and component failure so that solar energy systems remain efficient throughout their entire service life, even under the influence of environmental factors.

Lifetime derivation through accelerated tests

Accelerated ageing tests under more stringent conditions are a common test method for checking the quality of materials and manufacturing processes. The tests simulate the influence of moisture, radiation and temperature, for example.

One difficulty is to derive the expected service life from the test results, as the conditions during the tests are not necessarily representative of the actual environmental conditions. In our research, we focus on determining material-dependent constants through targeted accelerated tests. The constants serve as input for lifetime models that allow predictions about the durability of materials.

Accelerated ageing is also a useful tool for selecting between different material options or manufacturers for specific applications. For material manufacturers, accelerated ageing is an important quality control tool. It helps to identify potential problems in the coating lines and ensure that the materials produced meet high standards.

Research into component durability at various locations

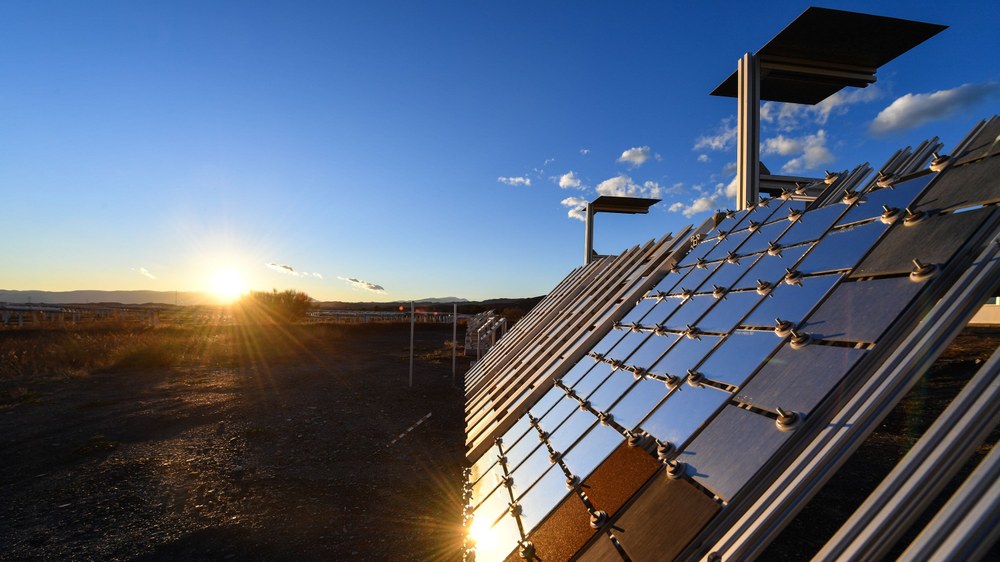

Research into component durability focuses on the ageing behaviour of materials with optical coatings. Our scientists investigate reflectors, absorbers and glasses with anti-reflective or protective coatings against soiling for solar power plants, photovoltaics or other energy technology applications to ensure their durability and efficiency.

The researchers are testing the resistance of materials and their coatings by exposing samples at twelve locations in different countries, including Spain, Portugal, Morocco, Chile and the United Arab Emirates. The Institute of Solar Research has set up this outdoor weathering network in collaboration with various partner institutions.

In the OPAC laboratory of the Plataforma Solar de Almería (owned and operated by CIEMAT), scientists from the German Aerospace Center (DLR) and CIEMAT investigate and characterise the degradation effects resulting from the exposure of the samples. Various measuring devices are used here, including prototypes developed by DLR and CIEMAT. In addition, climatic chambers are available to carry out accelerated ageing tests.

Goal: Service life estimates and standardisation

The overarching goal of the research group is to develop service life estimates for materials and coatings. These estimates enable predictions to be made about how the efficiency of the materials will change at different locations during operation.

The scientific findings also serve to standardise suitable measurement and test protocols in order to standardise the performance assessment of materials and make it comparable. The standards make it easier to derive suitable measures for improving the performance of solar technologies and are thus intended to improve the data basis for service life predictions.