Increasing the efficiency of hybrid solar power plants

Concentrating solar power plants are considered an essential part of the renewable energy mix due to their high efficiency and cost-effective energy storage options. Solar tower systems that use solid particles as a heat transfer and storage medium, in combination with concentrating photovoltaics (CPV), offer the potential to reduce weighted energy costs.

The researchers evaluate the cost saving potential of hybridising concentrating solar power plants by integrating CPV modules into the radiation shield of a particle receiver to utilise otherwise lost scattered radiation. Simulation results for a commercial configuration show that annual electricity generation can be increased by up to 12 per cent, with the weighted Levelized Cost of Energy (LCOE) of the CPV component ranging from 0.02 to 0.024 euros per kilowatt hour.

Increasing the energy yield by integrating CPV modules

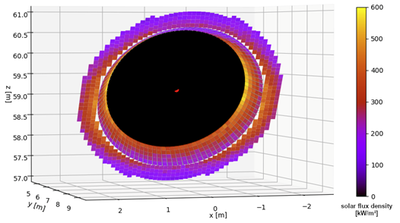

In solar high-temperature receivers, a relevant proportion of the concentrated solar radiation is lost as so-called spillage loss because it does not hit the actual receiver but the radiation shield at the edge of the aperture. As high radiation flux densities still occur in this area, special photovoltaic modules with multi-junction cells can convert this edge radiation directly into electricity with a high degree of efficiency.

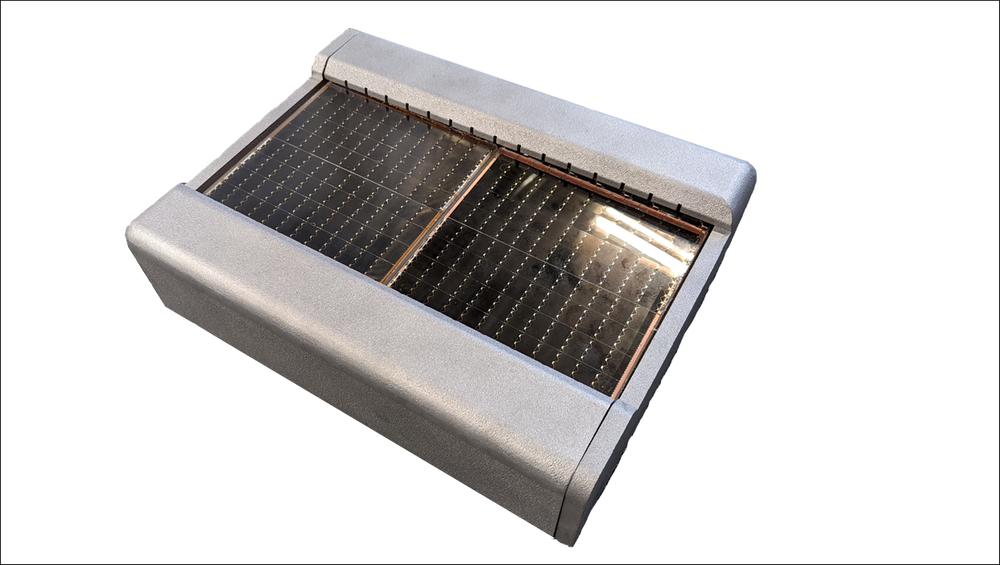

The techno-economic optimisation of high-temperature receivers leads to receiver designs in which up to 25 percent of the concentrated solar radiation hits the aperture edge constructed as a radiation shield and is therefore normally lost. This radiation can be utilised with so-called CPV cells (Concentrating PV). These CPV cells are optimised for high solar irradiance and can convert it directly into electricity with efficiencies of over 40 percent. Due to the high radiation flux densities, the CPV modules, on whose surface the cells are arranged, must be operated with efficient water cooling.

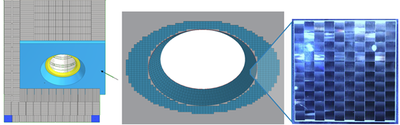

The following graphic shows the aperture surround of a high-temperature receiver, which consists of a conical part and a flat part. Each of the blue areas represents a CPV module with an area of 10 by 10 centimetres, a typical size for such modules. As part of the techno-economic optimisation, the additional electricity yields from the CPV modules are evaluated in conjunction with the additional costs in the overall system. In addition to the costs for the CPV modules, further costs are incurred for the water cooling and the electrical wiring.

Technical and economic evaluation and tests under real solar conditions

The potential of CPV modules was evaluated in the example of a modular solar power plant with a particle receiver. The receiver has an aperture diameter of 3.1 metres and a thermal output of 12 megawatts at the time of design. The spillage loss without CPV modules is around 24 per cent.

In an optimised configuration with a CPV system, over 1,200 CPV modules are used in the conical and flat parts of the aperture perimeter. This allows the annual electricity yield to be increased by almost 24 per cent, while the electricity generation costs are reduced by over 13 per cent in this case. However, the additional electricity generation via the CPV modules roughly corresponds to the thermal receiver output when the sun is shining. In contrast, electricity can also be generated at night from the thermal receiver output via a heat storage system.

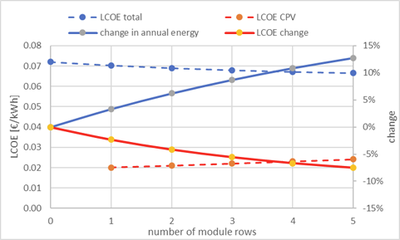

For the annual assessment, the additional electrical energy and the associated costs were calculated for a different number of CPV rows in the conical section.

The figure above shows the results of the evaluation. Depending on the number of CPV rows installed, up to 12 per cent more energy can be generated per year by using the otherwise lost scattered radiation. Extracting the LCOE of the CPV subsystem results in a range that starts at around 0.02 euros per kilowatt hour and rises to around 0.024 euros per kilowatt hour if more CPV modules are installed in less irradiated regions further away from the opening. This is an attractive cost level for the additional power. With the additional cost of the CPV subsystem, the LCOE cost of the hybrid system is reduced by up to 7.5 per cent.