Heat transfer medium – ceramic particles

Thanks to their high thermal stability and storage capacity, ceramic materials offer a promising alternative to conventional systems for solar thermal applications at high temperatures. Ceramic particles made of sintered bauxite are currently favored as heat transfer media. The reasons for this are:

- High temperature resistance up to over 1,000 degrees Celsius

- Due to their almost black color and the associated high absorptivity of 0.8 - 0.95, they are ideally suited for the direct absorption of solar radiation.

- They have a high heat storage capacity due to their high heat capacity and high temperature spread between the lower and upper operating temperatures.

- The particles are available in industrial quantities as they are used in the oil and gas industry to keep hydraulically created cracks open (fracking).

The particle costs are comparable to those of molten salt, the current standard storage material in the concentrated solar power sector.

Current work at DLR

- Analysis of novel concepts for particle receivers

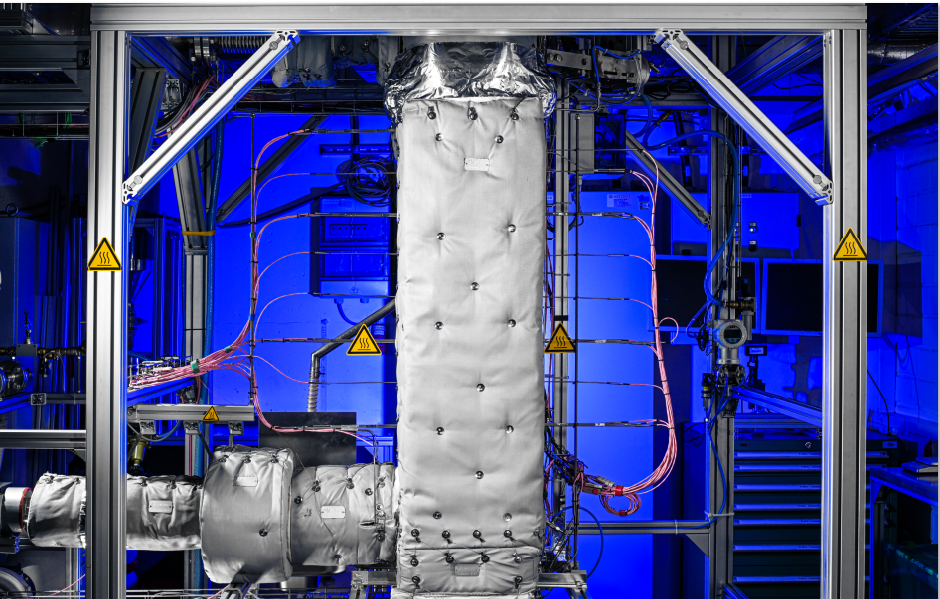

- Development, design, construction and production of:

- components for laboratory tests

- prototype receivers

- receivers for demonstration facilities

- Development of calculation models for

- Deisgn

- Construction

- Efficiency evaluation and determination

The DLR solar researchers are pursuing two application paths with the new technology:

- For solar thermal power generation, the increased operating temperature of the heat transfer and storage medium opens up the new possibility of driving state-of-the-art, highly efficient steam power plants with steam temperatures of up to 620 degrees Celsius exclusively with solar energy and generating electricity flexibly as required thanks to the integrated heat storage system. With the molten salt used as a heat transfer medium in current commercial solar tower power plants, solar power plants currently only reach steam temperatures of a maximum of 540 degrees Celsius. The higher operating temperature leads to higher overall conversion efficiencies and thus reduced electricity generation costs.

- The second area of application is in the field of solar high-temperature process heat with high energy requirements and high CO2 emissions. Cost estimates for the use of particle technology have shown attractive amortization times for foundries, for example.

The cost reductions are achieved by several factors. Firstly, direct irradiation of the particles in the receiver avoids the need to use expensive metal pipes through which the heat transfer medium flows. At the same time, high receiver efficiencies are achieved through direct irradiation. On the other hand, the largely free choice of temperature range allows techno-economic optimization, which leads to a significant reduction in heat exchanger and storage costs. Further advantages are the ceramic particles consisting of bauxite (essentially aluminum oxide), which are environmentally harmless. As the particles – unlike the liquid salt currently used – cannot freeze, the otherwise necessary heating of pipes and components during downtimes can also be dispensed with. This saves costs and eliminates the energy required for heating.