Molten salt systems – Towards a sustainable energy future with higher fluid temperatures

The continuous use of solar radiation to provide CO₂-neutral process heat and green electricity sounds like a vision of the future – but this is precisely what the staff at the Institute of Solar Research are working on. The focus is on the use of molten salts as a heat transfer and storage medium. While solar tower power plants already use liquid salt, many existing parabolic trough power plants still use thermal oil. The use of salt opens up completely new possibilities here:

- Higher temperatures: Liquid salt at over 550 degrees Celsius enables steam power processes to be operated efficiently to generate electricity.

- Better efficiency and storability: Salt can absorb the energy directly and store it for the long term, making it available as required.

- New applications: The high system temperatures with molten salt make it possible to provide industrial process heat in an economical and sustainable manner.

The aim is for the solar-generated high-temperature heat to be used not only for climate-friendly electricity, but also to supply energy-intensive industries with heat. Thermal molten salt storage tanks enable a flexible and cost-effective energy supply around the clock.

Parabolic trough power plants rethought

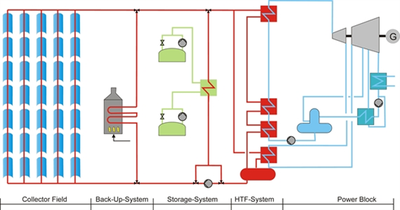

Conventional parabolic trough power plants use thermal oil as a heat transfer medium, which is heated to a maximum of around 400 degrees Celsius. The heat is transferred via heat exchangers to a steam power process to generate electricity. Excess heat can be temporarily stored in salt storage tanks and utilised later. The problem is that the process temperature is limited by the oil - whereas the molten salt in the storage tanks would allow much higher temperatures. In addition, an oil-salt heat exchanger is always required to transfer the heat to the thermal salt storage tanks. This increases the investment costs, the system complexity and reduces the overall efficiency of the system.

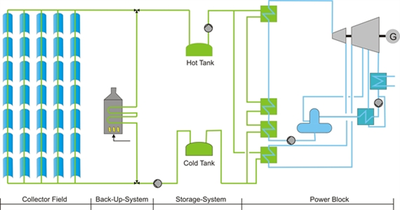

Researchers at the Institute of Solar Research are therefore developing the next generation of parabolic trough power plants, in which the thermal oil is completely replaced by molten salt. This allows significantly higher temperatures to be achieved, which:

- improves the efficiency of steam power processes,

- opens up new industrial applications for process heat,

- and increases system efficiency by eliminating the need for additional heat exchangers.

Lower costs and greater benefits

Liquid salt offers decisive economic advantages over thermal oil:

- Cheaper procurement: salt is cheaper than thermal oil.

- Fewer technical components: There is no need for heat exchangers between the oil and salt circuits, which reduces investment costs and system complexity.

- Higher operating temperatures: This reduces electricity and heat generation costs.

Established concepts rethought

The use of liquid salt is not new:

- The US "Solar Two" project (1996) and the Spanish Gemasolar power plant (2011) already used molten salts for heat storage.

- The experience gained from these projects provided valuable insights into trace heating, material resistance and operational safety.

However, molten salt technology is still in its infancy in parabolic trough systems. Pilot and demonstration projects are therefore essential in order to further develop the technology and enable it to be used on an industrial scale. Our research approach at the German Aerospace Centre (DLR) builds on this experience and translates it into parabolic trough power plants operated directly with salt, which can provide not only electricity but also process heat for industrial applications.

Technical and economic challenges

Handling and operational safety

- Liquid salts require new operating strategies, for example for filling and emptying the system.

- Emergency plans and blackout strategies must be developed specifically for operation with salt.

- Freeze protection: Liquid salts must not be allowed to freeze in pipework and storage tanks.

More efficient salt handling: Dilution with water lowers the melting point and reduces losses

- The melting temperature of solar salt at around 235 degrees Celsius requires technical expertise to prevent solidification.

- By adding water, the solidification temperature of the salt can be lowered to below 50 degrees Celsius, which reduces heat losses and makes handling easier.

- The long-term stability and corrosion resistance of diluted salt mixtures must be investigated further in order to control material degradation and vapour pressure effects.

Development of suitable collectors

- Parabolic trough collectors need to be adapted for higher temperatures.

- The mechanical resistance and tightness of flexible pipe connections must be further developed and tested.

Solar preheating of the receivers

- The receivers can be additionally heated with "impedance heaters" (direct electric heating of liquid salt), for example, to prevent the salt from freezing when filling the solar field, but also to thaw frozen salt locally.

- Solar preheating of the receiver pipes is a new approach to eliminate the need for additional technical and financial expenditure for heated receivers in the future.

Improved salt mixtures

- The optimum salt system must combine a low solidification temperature with high thermal stability in the upper temperature range.

Corrosion and material selection

- Salt reacts with certain materials. Coatings and new materials are necessary to ensure the longevity of the systems.

Large-scale demonstration

- While solar tower power plants already work with molten salt, there is a lack of large-scale reference projects for parabolic trough systems.

- Pilot plants are needed to establish the technology on a broad scale.

Molten salt – a key to the energy transition

Molten salt systems offer enormous potential for the combination of solar energy, efficient power generation and industrial process heat.

- Social benefits: A clean, affordable and independent energy supply

- Economic benefit: Lower operating costs and new business areas for plant engineers and component manufacturers

- Political relevance: An important building block for achieving climate targets through the decarbonisation of industrial processes

- Sustainable energy supply: Concentrated Solar Power plants with molten salt can be optimally combined with wind and photovoltaics to create a flexible, stable and climate-friendly energy system.

- Backup heaters utilised to serve the grid: In addition to bridging solar deficits, the electrical backup heater can in future absorb surplus electricity from the grid and store it as heat in molten salt. This will enable solar thermal power plants to actively contribute to grid stabilisation in a renewable energy system in the future.

The DLR Institute of Solar Research is convinced that molten salt systems, with their high operating temperatures and excellent storage capabilities, will play a central role in the global energy transition. Together with industrial partners and research institutions, they are developing practical solutions that combine sustainability and cost-effectiveness – for a low-carbon, future-proof energy supply.