The advantages of air systems are obvious: air is non-toxic, freely available, stable and remains gaseous over a very wide temperature range. It therefore makes sense to use air as a heat transfer medium in solar thermal systems. A considerable proportion of conventional plant technology can also be used in solar thermal systems.

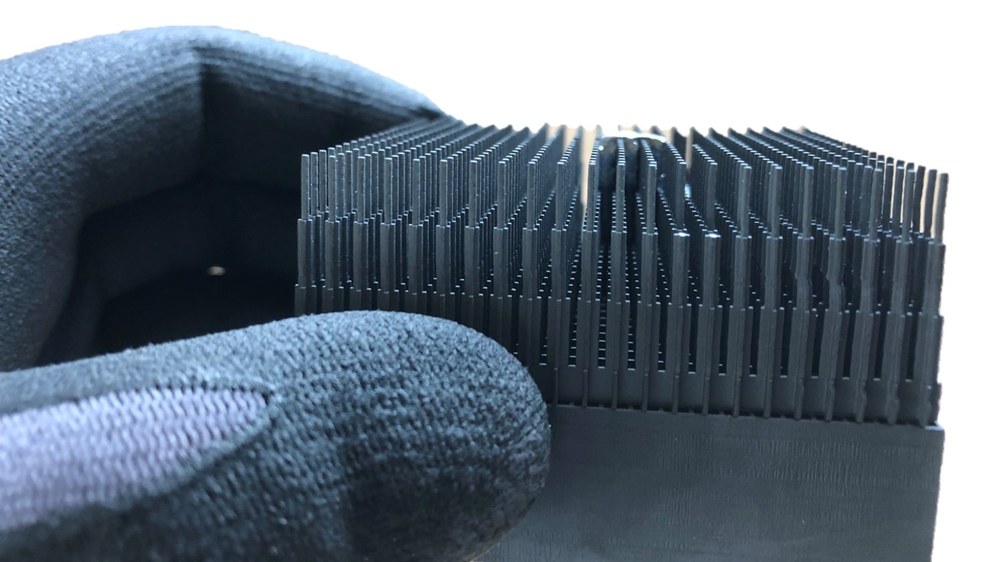

Nevertheless, the fundamental problem of the poor thermal conductivity of air remains. How can solar heat be transferred to air without having to accept extremely high temperature differences? The key lies in the surface used: a porous structure whose inner surface is several orders of magnitude larger than the irradiated frontal surface serves as an absorber. The concentrated solar radiation is absorbed in the depth of the structure and transferred as heat to the air flowing through it. We therefore speak of volumetric radiation receivers. If it is possible to absorb the radiation very deeply in the porous structure, the losses are minimised and the conversion efficiency reaches values of over 90 percent.

Two fundamentally different types of receiver systems have been developed to date: Closed (pressurised) and open receivers.

Closed volumetric receiver

The central element of the closed volumetric receiver is the internally insulated pressure vessel, which is sealed off from the environment by a domed quartz glass window. In the inside are ceramic or metallic volumetric absorber elements. The concentrated solar radiation penetrates the quartz glass window, is absorbed by the absorber structure located behind it and transferred as heat to the air flowing through.

This type of receiver is used to transfer solar energy to the heat transfer medium air in the high-pressure section of a gas turbine process. The compressed air (10 to 15 bar) is fed into the receiver and heated to around 600 degrees Celsius with metallic absorber material or to over 1000 degrees Celsius with ceramic absorber material. If the air temperature is below the defined turbine inlet temperature, it is heated even further in a downstream burner.

The maximum size and output of this type of receiver is limited due to its design. In order to achieve higher outputs, several receivers must be arranged next to each other and connected in parallel. For this purpose, they are equipped with a secondary concentrator, which allows many receivers to be arranged on one tower without any gaps.

Open volumetric receiver

With the open volumetric receiver, the porous absorber modules are exposed so that they can be directly exposed to concentrated solar radiation and the ambient air can simply penetrate. Here too, both metallic and ceramic materials are used as absorber materials.

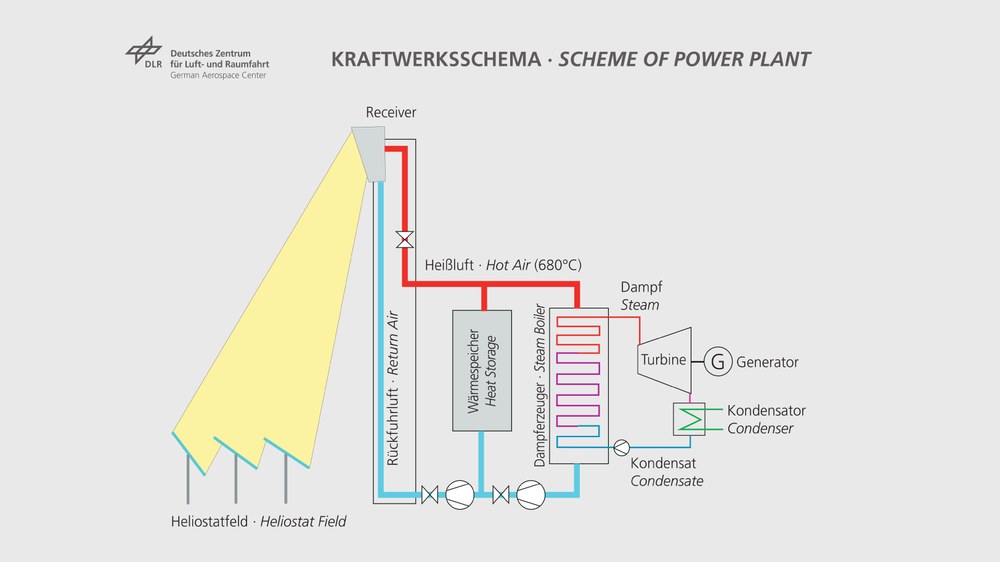

For power plant applications, the air is heated to around 700 degrees Celsius. It is then fed into the boiler of a water-steam cycle to convert water into steam, which drives a steam turbine to generate electricity. Alternatively, the heat can also be transferred to a thermal store. The cooled air from the boiler or storage tank is returned to the receiver with a residual heat of 100 to 150 degrees Celsius and directed in front of the irradiated receiver surface to be utilised again. As not all of the air can be drawn back in, this is a non-closed air circuit.

The open volumetric receiver has a modular design consisting of a few basic components for easy scaling to different output sizes. The central component is the absorber module, consisting of the absorber structure, which is mounted in a retaining cup. These absorber modules are held in a metal support structure and grouped together to form a receiver surface of any size.

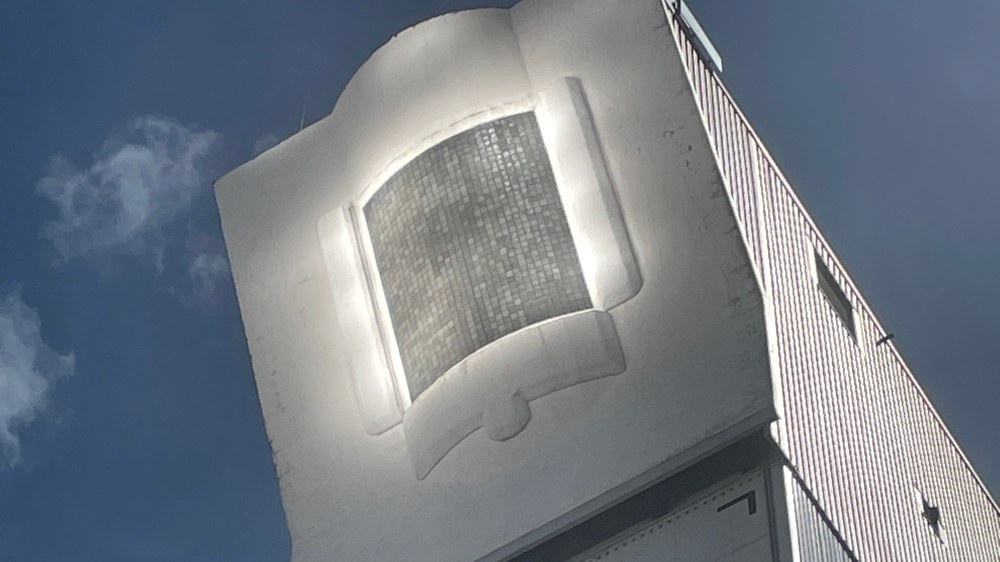

Solar Towers Jülich

The technology of volumetric receivers has been continuously developed at DLR since the 1990s. The first of the two Solar Towers Jülich, the largest system to date, was built in 2009 as a demonstration and test facility for open volumetric receiver technology and has been operated by DLR since 2011.

In research projects, our scientists are investigating, among other things, how the efficiency of these technologies can be improved. For example, they analysed the influence of wind currents on the open volumetric receiver and how this can be reduced. In addition, new ceramic 3D screen printing techniques were used to create delicate absorber structures for higher efficiency.

Advantages of air systems

- Non-critical heat transfer medium

- Largely conventional plant construction

- Simple, cost-effective solid heat storage available (open system)

- Easy to hybridise with gas/biogas

- Well suited for retrofitting existing steam power plants

The open air system can also be used very well to provide process heat at any temperature level between 400 and 800 degrees Celsius. This can be used for drying processes, for example. This can be interesting for drying processes in mining and the chemical industry, for example.